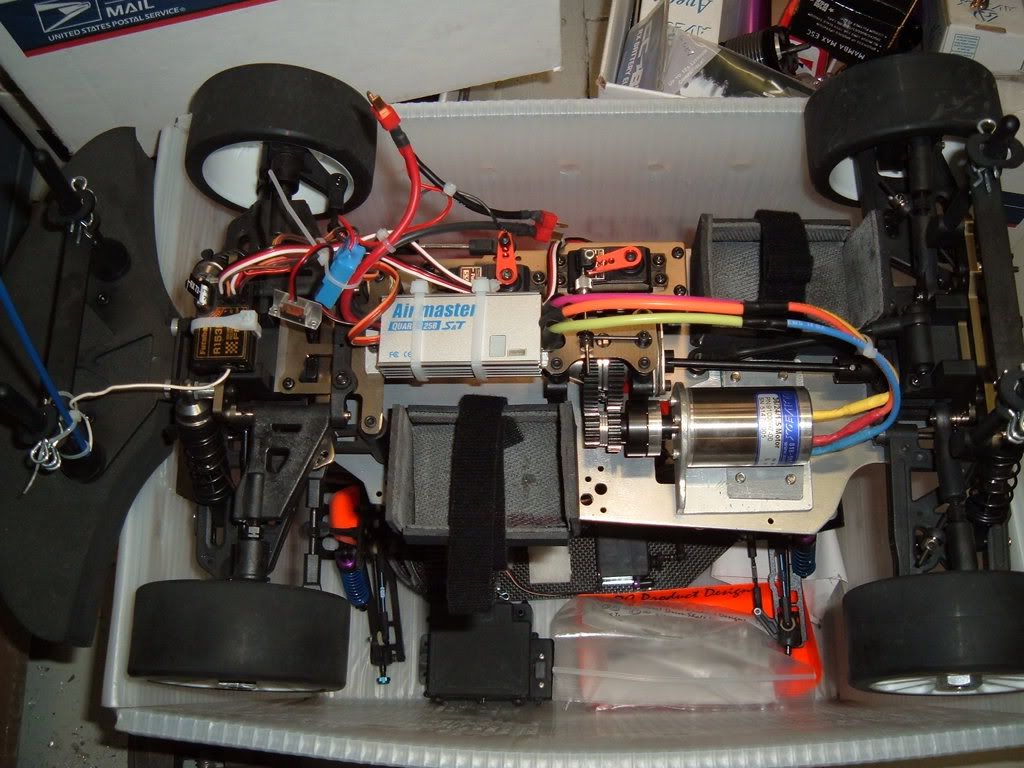

Put some wrench time on this car today. I put the replacement clutch adapter on, and it runs true, no wobbles! Set the mesh, programmed the radio and went out for a test run. I left the quark airmaster 125 and the aveox 2600kv motor in for the time being, and am using a 4s 6000 lipo. Plenty of power from the aveox, but it was not shifting into second. Tried adjusting it, but did not have any success.

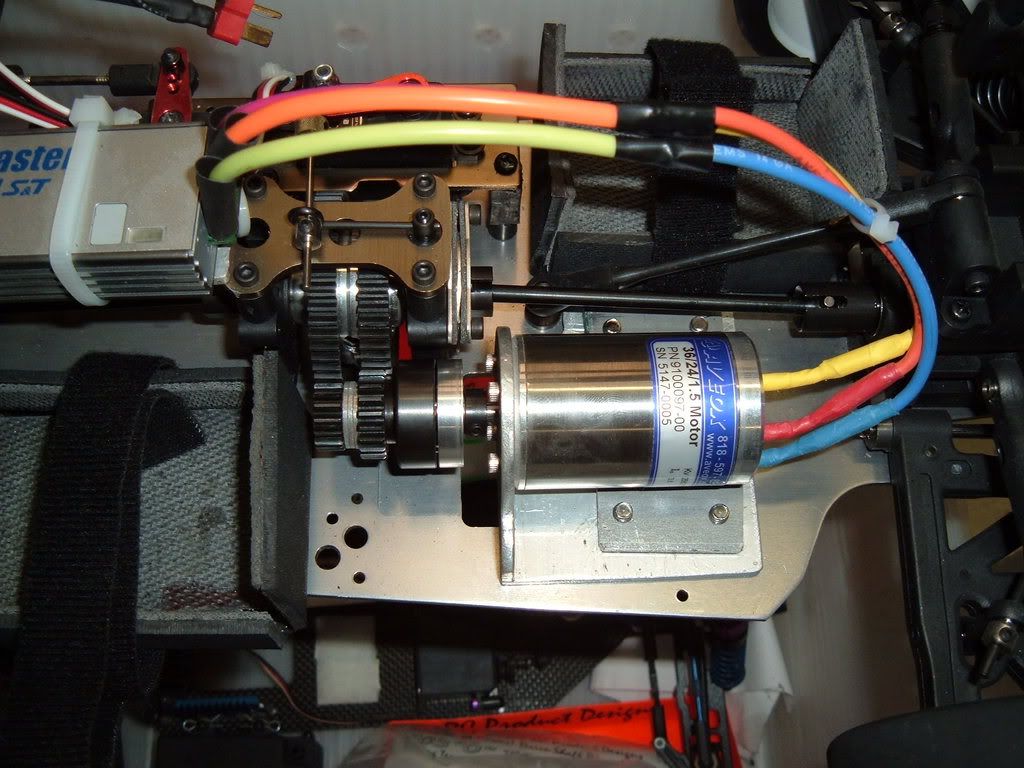

So I took the 2 speed apart, and had a good look at it. What I thought was the adjusting screw was actully not. Turn out the shifting mechanism is controlled by a clutch. It is a circular platic disk about 8mm thick that is cut in half, and has 2 bolts with springs holding the 2 halves together. Those bolts are placed near the ends of the 2 halves. Each side has an adjustment screw in the center of the clutch shoe with a ball bearing behind it. The main shaft has a hub machined on it with 2 flat spots. They act as ramps, and as the spring pressure is relieved by the centifugal force the ball bearings ramp along the flat areas, causing the 2 halves to seperate and make contact with the clutch bell area of the second gear hub.

Problem is, the springs are too heavy, and no amount of playing with it would make it work. I ended up taking one of the bolts and springs out, so that side can open up and grab the bell, much like a drum brake on a car. That worked, and I bench tested the setup a few times. Took it apart and the shoes had a nice wear pattern over almost 360 deg of the surface. Hope this works, as I am anxious to see how well this works on 5s!

Then it rained, so no testing

heres a few pics, the wiring is tempory till I get some performance testing done and decide if I like it this way.