Havok,

Moving the steering servo linkage to the top of the arm works perfectly. Only downside is the the threads for the ball stud that stick out the bottom of the servo saver arm aren't long enough to reach the nylon lock inside the nut that goes on the bottom. So you need to use some threadlock on it. But it works perfect and the linkage alignment is perfect. We payed close attention to get the alignment of the llinkage in the correct position to have ideal geometry.

Mike should have included a couple 3mm flat nuts in the package. take one of those nuts and thread it all the way onto the threads of the ball stud so its up against the flange on the ball stud. Then when you put the stud through the servo saver arm it will fill the gap that was intended for the nut when the linkage is installed on the bottom of the arm.

Durability is not an issue. Ive been driving mine like this for almost a year and have had no problems or ill effects from it.

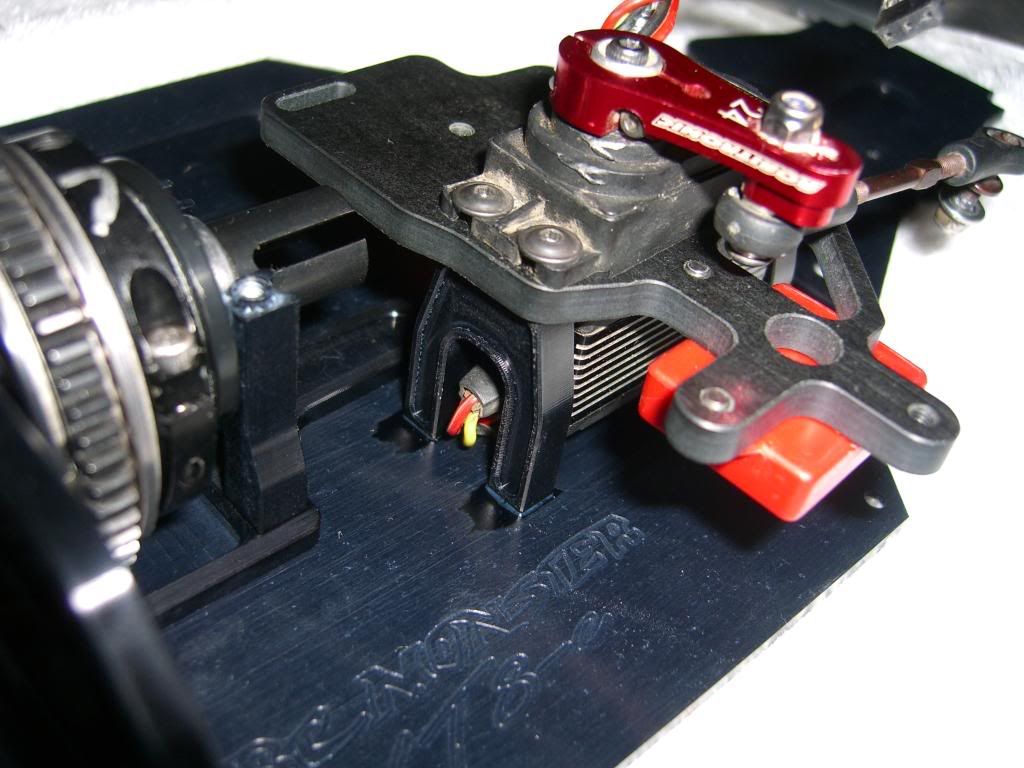

Here is a quick picture of it flipped and installed on mine.

I will post up an instruction sheet on how to do this install in the next day or so to avoid any future confusion.