Securing the spindles to the front arm, again the hinge pin is captured by a small screw on the back side of the arm (they used the same technique on the spindles as well).

Now it was time to build turnbuckles. This is potentially my least favorite part of building a kit; though it's competing with building shocks and gluing tires. These were actually super easy to build and of a very nice quality. Notice that there is a long end and a ...less long end for each turnbuckle. They looked the same to me until I looked a little harder. I decided to put the long end to the outside on all the turnbuckles and made sure to align the notch in the turnbuckles to one side so they all adjust the same direction. I actually just started them by hand, snapped them on carefully (so they didn't pull out of the ends) and then used pliers to draw them up. Took a lot of the pain out of this step, though a tool from Kyosho for this purpose would have been nice. I will say these are the first turnbuckles I've built where the pliers didn't gall them up. The finish on these is very resiliant.

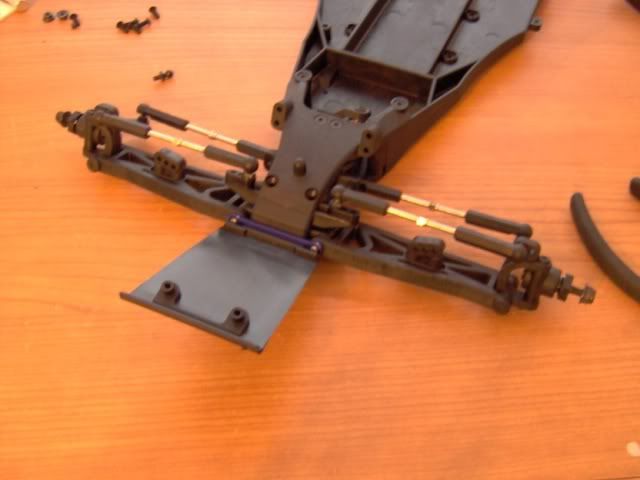

Just another quick shot of the assembled turnbuckles from another angle.

Then we dig through Bag B for some bumper pieces and get those installed. I like these bumpers, though they do seem to have a bit more flex that other trucks I've seem, I wish RPM would release a bumper like they did for the Slash and SC10 for this truck. The ease of only having lower attachment points and the stiffness they built into the plate would be a nice addition to this truck.

Now to the ball diff... the bane of my existance.