Yeaa brainanator these types of projects takes LOTS of patience. I have been lucky enough with this build where I haven't had to re-make parts because I messed up on the first one..on some projects I have to remake a single part two or three times.

Yep, I definitely don't have the money to get stuff CNC'ed so hand tools it is... amazingly though..to this day I still don't own a Dremel. Perhaps that would make stuff easier.

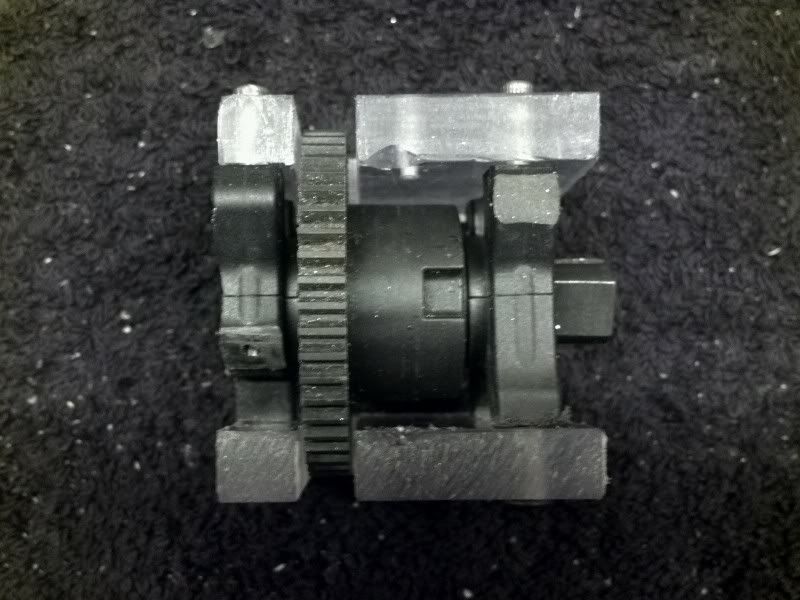

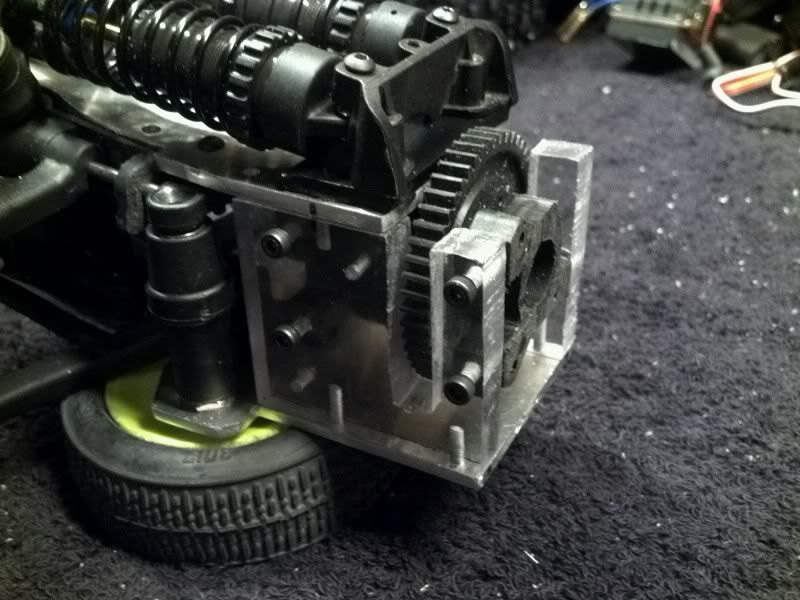

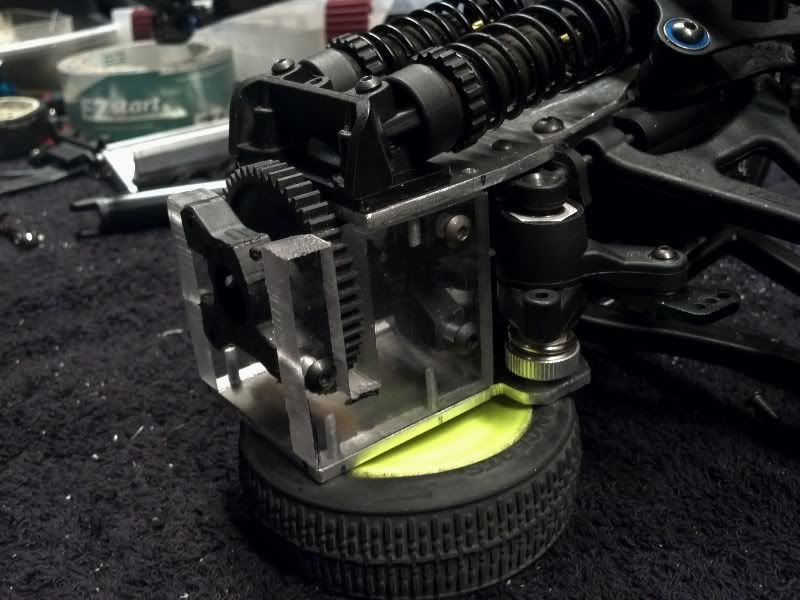

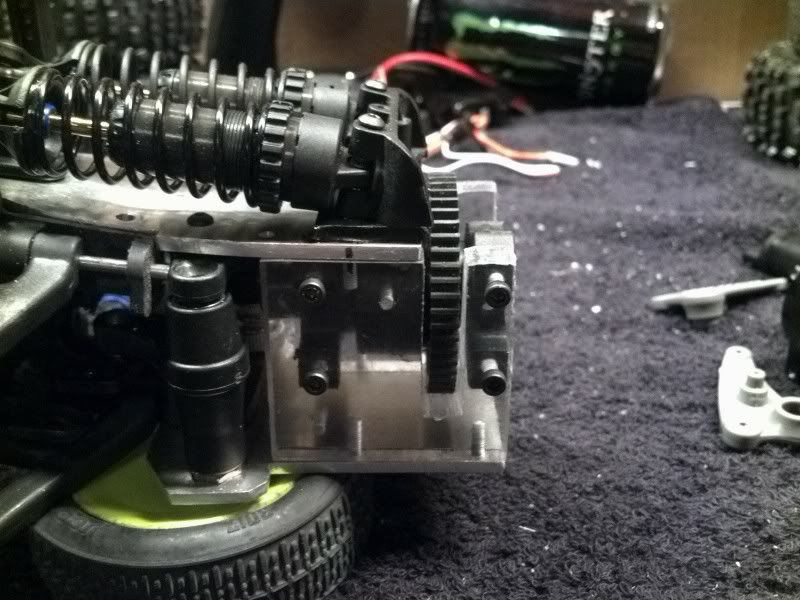

I finally got the front chassis braces done and mounted today. These parts took some time because I had to make sure that I had the holes in exactly the right spots so that that the center differ would be straight and would spin freely. I also had to make sure the tops and bottoms where completely flat and that my cuts where straight so that these parts would fit flush and weren't crooked.

Once I got the pieces cut and drilled then it was another challenge to mount them to the upper and lower chassis. These parts have to be square and straight so that the TVP's will be parallel and won't be crooked.

I think I ended up doing a pretty good job considering that I'm useing hand tools and I'm happy with how it fits together. I think it will prove to be very durable

I also discovered today that Long Travel Rockers fit the front of the Slayer but will NOT fit the rear becuase the push-rods interfere with upper a-arm. So I will be have to use P2 rockers on the front and back.

The front clip as it stands..

Now that I have the majority of the front clip completed I'm going to start working on the rear clip. Once I get the rear clip done I will finally be able to design and fabricate the chassis plates!