|

|

|

Who figured out the plastic center diff spur? |

|

|

(#1)

|

|

|

Guest

Posts: n/a

|

Who figured out the plastic center diff spur? -

05.20.2009, 01:30 AM

Just curious what anyone came to?

I may start on my .5 again, and was curious what anyone did. Since my steel spur is messed up, and I dont want to pay for a new gear (pretty pricey) so that and plastic is nice and quiet  I dont mind modding the chassis a little bit. But LMK |

|

|

|

|

|

(#2)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

05.20.2009, 09:48 AM

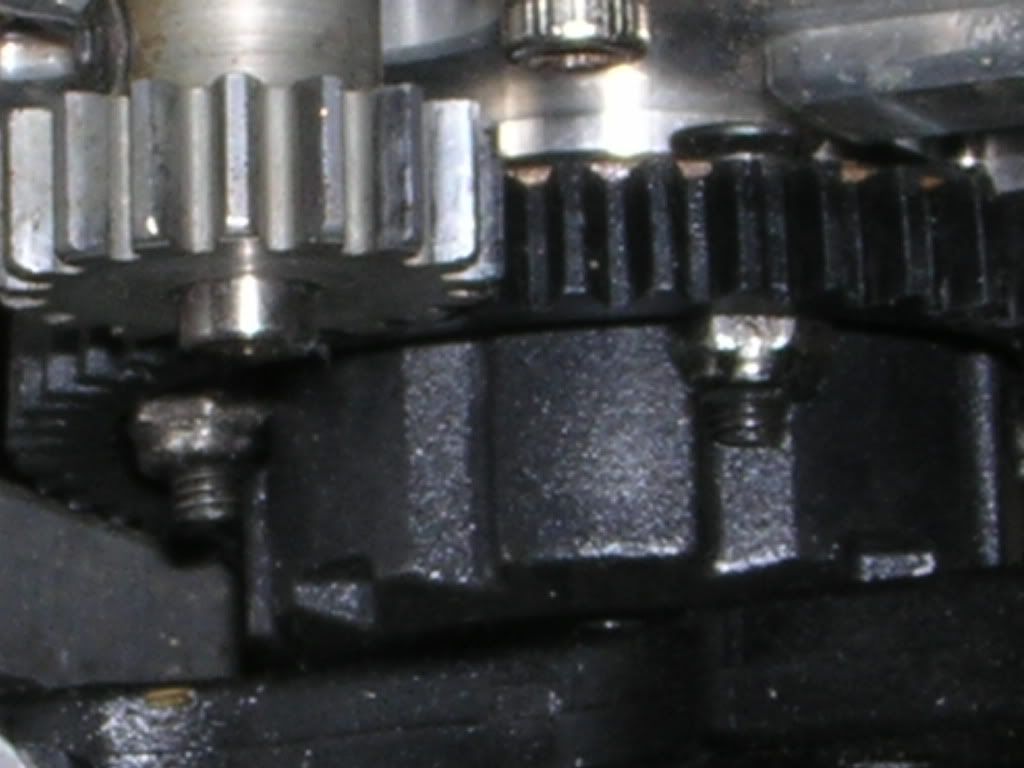

I took a 46t kyosho plastic spur, and had the machinist open up the center hole so that it fit around the diff cup. Then I took the steel spur to the grinder and removed the teeth and a little more. So basically I made a backing plate out of the steel spur. It is hardened so drilling it was not an option. I made 4 slots with a fiber cutting disk, and then drilled 4 holes in the plastic spur. Bolted the spur to the backing plate with nuts and bolts, plastic spur on the diff cup side. Last I made some 1/4" or so plastic spacers to put under the diff bulks to raise the diff enough so that I did not have to enlarge the hole in the chassis.

|

|

|

|

|

|

(#3)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,609

Join Date: Aug 2008

Location: Bozeman, Montana

|

05.20.2009, 10:52 PM

Quote:

EDIT: Pics:

|

|

|

|

|

(#4)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

05.20.2009, 11:54 PM

Yup thats it. Unusullied, you should start taking pictures of Bigfoot or the Loch Ness Monster... That way we can get a slightly better look at them

|

|

|

|

|

|

(#6)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,609

Join Date: Aug 2008

Location: Bozeman, Montana

|

05.20.2009, 11:55 PM

Nobody has been willing to pay my price for those pics

|

|

|

|

(#7)

|

|

|

A Horse's Ass

Offline

Posts: 1,065

Join Date: Oct 2007

Location: Spokane WA

|

06.05.2009, 07:36 AM

Here's a thread that might spawn some ideas for you.

http://www.rc-monster.com/forum/showthread.php?t=17962 |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode