|

|

|

Brushless lightning stadium |

|

|

(#1)

|

|

|

Guest

Posts: n/a

|

Brushless lightning stadium -

06.14.2006, 06:48 PM

I dont see a dedicated thread so far to doing this so I think I shall do one, and hope that it will encourage others to dive in there and get creative.

I am no master machinist or fabricator like alot of people on this forum. I'm simply a 14yr old with a dremel and a bit of common sense. All i needed to do this whole conversion is simply a 12V power drill and a dremel. I received a Lightning Stadium RR today in the mail (My mum wasn't terribly happy!) with the intention of creating the first brushless truggy in Scotland. Firstly, I removed the engine, pipe, fuel tank, radio box and throttle servo. I first cut off the area where the throttle servo was, as it protrudes the area where the cells and centre diff gear will go. Next; for some strange reason, Hot Bodies decided to cut the rectangle for the centre diff to the one side, so I had to cut the chassis at that are so I could reverse the centre diff for the motor to hang towards the front of the truck. Next thing on the list was the motor plate. The first thing you think when you see the motor plate is "This circle in the middle is where the drive cup can go through". Wrong! Because of the motor mounting bolt positions (assuming you have used the old brake mounting holes), they rub against the motor, and it cant be used. ... Continued tomorrow with more info and some pics (It's midnight!) Darren |

|

|

|

|

|

(#2)

|

|

|

RC-Monster Admin

Offline

Posts: 10,480

Join Date: Feb 2005

|

06.15.2006, 04:48 AM

I thought i did one of these? there should be a thread around here somewhere..

|

|

|

|

|

|

(#3)

|

|

|

Guest

Posts: n/a

|

06.15.2006, 01:13 PM

I couldn't see it?

I dont mean that no one else has threads on it, I just want to make one that is really simple. |

|

|

|

|

|

(#4)

|

|

|

Guest

Posts: n/a

|

06.15.2006, 06:41 PM

Continued from last time...

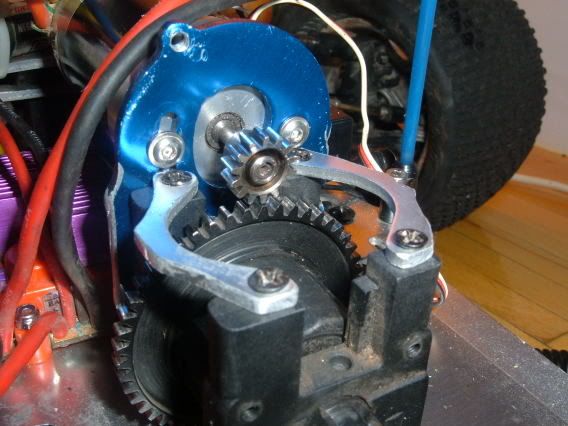

This was because I planned to sit the motor to one side of the centre diff. However, I quickly changed plan and decided to mount the motor ontop of the centre diff. Now by doing this, you can utilize the hole i mentioned earlier. You can see in this picture:  The red line indicates the edge of the circle. If anyone would like a close-up of the motor plate mounted or un-mounted, please ask and I will get one for you. Now, to attatch the motor plate to the centre diff. I didn't think that two 2.5mm self tapping screws would cut it. I took the drill to the holes and enlarged them to 3mm. Then I counter-sunk the inner side (Diff gear side) of that block to bolt the motor plate on. It seems prety solid. Next, the centre diff brace. As standard the centre diff brace is some space ship-shaped item instead of a simple square. If you cut this so that it looks like a bracket, one of these ( then you will be able to use the other side of the bracket to make the new 'bracket'. Now there is no flex in the mount as before. Now we have to mount the esc. From this picture:  You can see the area marked out where the ESC can go, plenty of room. You can velcro this on, use a strap, cable ties, or make a plate and bolt it on. I bolted mine on. Lastly is mounting the batteries. This is an easy step. If you have some battery straps, simply put 4 holes in your chassis (2 per side) and counter-sink them on the underside and put a nut on the battery strap washer. Easy. And that's you pretty much done any other personal touches wont take very much work, cable tie-ing ubec's on etc... All I needed To do this whole conversion was. Maxx Motor plate (Now quarter of original size :018: ) Battery Straps That's it. Simple. Remember, All I had was a dremel and a 12V cordless drill. None of this pro lathe cnc stuff. I didn't even use a vice, I used a person. His thumbs are a little burnt from the heat of the motor plate, but he'll live. Any pics etc..., needed, just ask. |

|

|

|

|

|

(#5)

|

|

|

Guest

Posts: n/a

|

06.15.2006, 07:18 PM

Good job Darren, Heath Robinson would be proud.......,:027:

No seriously, good effort. Its good to show that leccy conversions can be done simply. The maxx motor plate is easily adaptable for most centre diff mounts, I wonder if two screws is enough to hold it on though....Knowing how you drive, like.:030: time will tell I guess. :027: |

|

|

|

|

|

(#6)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 116

Join Date: Aug 2005

|

06.16.2006, 02:06 AM

Nice and clean conversion so far!

But are you going to drive with that steel spur? Don't you change it to a nylon? |

|

|

|

|

|

(#7)

|

||

|

Guest

Posts: n/a

|

06.16.2006, 11:05 AM

Quote:

Jasper, well here's the thing, is kinda a trap for my dad. I actually converted this for him, so I'm hoping that when he puts his HV-Maxx (its spare so might aswell try it) into this truggy, the pinion will get wrecked and he'll be forced to buy an XL with a hardened pinion :005: . Most change it to nylon, but i'll see if Mike can make a centre diff adapter for the ofna 51t spur gear 'after' dad gets the XL. This thing handles so much better than my Maxx. I like how I can use the stock maxx tyres wthout worrying about it tipping over. |

|

|

|

|

|

|

(#8)

|

||

|

Guest

Posts: n/a

|

06.16.2006, 04:26 PM

Quote:

How is DD by the way?? One thing I would say though is If you are Drilling or Dremmling anything, then use a vice or a clamp. Its very easy to make a mess of your fingers if you slip.........I sound like my Dad now :010: |

|

|

|

|

|

|

(#9)

|

|

|

RC-Monster Mod

Offline

Posts: 6,254

Join Date: May 2005

Location: Baton Rouge

|

06.16.2006, 01:51 PM

You might be able to just use the Kyosho spur. I'm almost positive that it will bolt right on.

|

|

|

|

(#10)

|

|

|

Guest

Posts: n/a

|

06.16.2006, 05:10 PM

DD (if you mean dad) is fine, and also has no clue who 'Heath Robinson' is.

Totally get you about the vice, I wasted 6 Dremel cutting discs because it kept back-lashing. Still, it's great when my friend Chris was holding the motor plate, 11 o'clock at night screaming because of how hot it was getting. Amateur engineering at its best! Yeah, you do sound like your dad, go sit in the corner :027: . Squee - Which one? |

|

|

|

|

|

(#11)

|

|

|

RC-Monster Mod

Offline

Posts: 6,254

Join Date: May 2005

Location: Baton Rouge

|

06.16.2006, 05:59 PM

The 44T Mike sells.

|

|

|

|

(#12)

|

|

|

Guest

Posts: n/a

|

06.16.2006, 09:24 PM

Quick history lesson for you and Dad. :dft009: http://www.worldwidewords.org/qa/qa-hea4.htm

do ya get me now :005: |

|

|

|

|

|

(#13)

|

|

|

Guest

Posts: n/a

|

06.17.2006, 09:55 AM

Yeah :) .

Here's a pic of the centre diff brace I was talking about. Bracket shaped thing.  I know, it's a 32p pinion, should have my Mod-1 pitch pinion from Mike on monday. Still haven't convinced dad to buy a real motor though :). |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode