|

|

|

Center driveshaft questions |

|

|

(#1)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

Center driveshaft questions -

11.06.2007, 10:54 PM

Ok guys, need some assistance here.

I have Metalman's old revo, with the homemade slipperential setup. I need some sort of cvd or dogbone for the front drive. The ends would have to fit the revo diff input (pinion) shaft, and have a revo style end at the trans/center diff. The center diff has mike's custom diff outputs to allow the stock driveshafts to be used. I currently have a stock driveshaft on the from, however it rubs the steering mount, and I have turned it down as much as I can. Mainly wondering if a cvd or dogbone would be better? I have a cvd rear shaft, and would like a cvd front. How would I measure the length needed? Front the non-cvd end to the center pin of the cvd end? Or the entire length without the drive cup? Any suggestions would be very helpful! |

|

|

|

|

|

(#2)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

11.06.2007, 11:12 PM

Did you buy the 1/8-to-Revo shaft adapters from Mike? If not, those are MetalMan-made as well

. But they are essientially the same thing as what Mike makes. . But they are essientially the same thing as what Mike makes.Unfortunately that center-front driveshaft is so large. If you remove the aluminum steering brace that the driveshaft rubs, you'll see that I cut that down about 1/8". Just wanted to add, that center-front driveshaft on there isn't actually stock, it's one from the wheels that I cut up to fit there, for the increased strength due to its larger diameter. Vantage makes a set: http://www.vantageracing.com/site/v2...ges/RE0003.jpg It retails for $35.99. You could ask them for the lengths of the driveshafts in the pic, to see if they would fit, or if they have any of a length that would fit the center-front. http://www.vantageracing.com/site/v2-contact.aspx |

|

|

|

|

|

(#3)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

11.06.2007, 11:27 PM

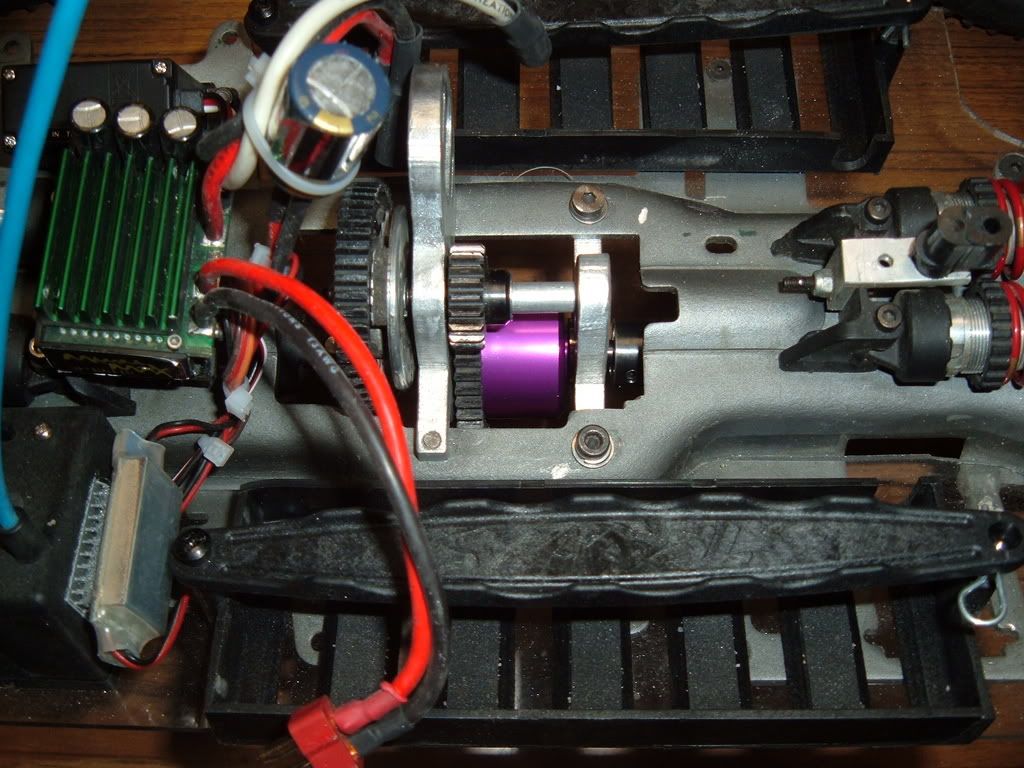

Oh, they looked just like the one that Mailman sent me that he got from mike. I also replaced the diff cup as the one on there had some wear on the cup where the rear shaft exits, had alot of side-to-side play. Heres some pics of what I have done so far, still waiting on some 44 tooth hpi spurs to mod, the 46 t mgt spur rubs on the front driveshaft too much for my liking. I also slotted the rear mount holes so that I could move the rear bulk closed and eliminate some of the spacers. I made a new top shaft spacer out of some al tube too. Nice job on those bulkheads, they must have taken a while to make!

Thanks for the tip, I will have a look at those cvds. I may hit up the lhs and see if they can help me out too. My buddy is the manager!!!   Still need to make a skid plate to mount onto those holes you drilled, and maybe make my dirt guards/battery tray mounts out of something else, they are a bit flexible right now in lexan! |

|

|

|

|

|

(#4)

|

|

|

RC-Monster Mod

Offline

Posts: 6,254

Join Date: May 2005

Location: Baton Rouge

|

11.06.2007, 11:22 PM

Just measure and find a dogbone to fit, or get Mike to have one made. to measure, just put cups on both ends and measure from the center of both drive cups and from the end of both and give those to Mike. That should tell him all he needs to know, but I'm just guessing...

|

|

|

|

(#5)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

11.06.2007, 11:29 PM

Quote:

|

|

|

|

|

|

|

(#6)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

11.06.2007, 11:39 PM

That purple diff cup was a throw-off! But I know what you mean about the wear on the Savage aluminum diff cup, with the wear that developed.

The center diff on there is essentially a Hyper 7/8 diff. That means that you can use pretty much and 1/8 scale diff outputs, that a dogbone would fit into. Like these: http://www3.towerhobbies.com/cgi-bin...?&I=LXCVR6&P=7 This will be a much sturdier way to do it than putting output cups on the current output shafts, and should also lessen wear due to a better fit. As for a center skid plate, just be sure that whatever you make allows the screw heads (of 4mm countersunk screws) to not stick out from the skidplate. Just curious, does the broken portion of the chassis at the rear of the stock motor mounting area not bother you? It didn't bother me, TBH. But that's one reason why I sent along a brand new 3.3 chassis to Mailman when I traded him the truck. |

|

|

|

|

|

(#7)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

11.07.2007, 12:31 AM

Quote:

I did enlarge the hole that the slipper shaft passes through, so that I could use one of the bearing races, that you we using as a spacer, as a spacer between the slipper backing plate and the bearing. I then placed the 20t gear on the slipper shaft with 2 traxxas washers between it and the bearing, so that the slipper shaft was held tightly from both sides of the bearing = no slop there. It also allowed me to use some thin wall al tube to space the other bearing in the rear bulk the correct distance away. Thus the slipper shaft spins very smoothly, and has no front to rear slop, and the backing plate can't contact the front bulk anymore. I guess that I am just improving on your design, which seems well thought out anyway. If you make another one of these may I suggest that you use a 46t spur on the ctr diff and a 20t gear like this setup. That would allow for the use of a mgt 46t spur on the slipper and give enough clearance to use the stock driveshaft with out any clearance issues with the spur. I have found some hpi 44 t spurs that may be able to be converted to use the revo slipper. i will get them tomorrow and see what I can do. The slipper and center diff really make the truck handle well and it does seem easy on the diffs too. I see that Mike is making an integrated center diff and slipper, will be nice for the truggy conversions! |

|

|

|

|

|

|

(#8)

|

|

|

HOOH HUAH HOOH! Aww Baby!

Offline

Posts: 868

Join Date: Oct 2007

Location: olyWA

|

11.06.2007, 11:44 PM

You mean drive cups? IMO, if you really want a bulletproof drivetrain you should use some 1/8 buggy diff cups and some nice steel shafts (read: RC Alloys). Shim your diffs well and you should be set.

|

|

|

|

|

|

(#9)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

11.07.2007, 01:04 AM

I too liked that chassis, that extra room for batteries was nice (especially since I was using a 3s2p A123 pack on the left side, which was about 200mm long).

I forgot that the holes the center diff's output shaft were smaller. Savage diff outputs should work fine. The holes on the bulks will have to be enlarged to 14-15mm, which will be tough without the proper size drill bit. It's great to see that you are improving on my design. The reasoning for the gearing was due to my motor choice, which was a 7XL. Originally, the bulks accommodated 18/44, but I changed it to 20/44 to match Mike's Slipperential ratio and to better suit more motors. Since I no longer have a Revo, it would be difficult to complete another set of these bulks since I have nothing to test-fit them to. I do still have the plans drawn up on my computer, and could easily modify them to alter the gear ratio. Then it's just a matter of printing out the plans, taping them to a piece of aluminum, and cutting/drilling them. |

|

|

|

|

|

(#10)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

11.07.2007, 01:10 AM

I will give the savage cup a try, should have a big enough drill bit handy. What cup should I use for the front diff? I have a variety of cups, generic, dynamite and mip, IIRC. They all look to be very similar, so I guess any will work ok. Thanks for the help and I will post some finished pics too!

|

|

|

|

|

|

(#11)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

11.07.2007, 03:15 AM

I would go with anything that will fit the end of the dogbone, but will depend on the diameter of it.

|

|

|

|

|

|

(#12)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

11.07.2007, 11:08 PM

Ok, I cut and welded an emaxx cvd to the correct length for the front driveshaft. I also filled the center diff with 50k traxxas diff fluid. Runs much smoother now and the spur is no longer hitting the front output shaft of the center diff. I also got my modded MM back from griffinru today and will install that along with a hitec 645mg servo. Should be a good basher now, everything is working well.

|

|

|

|

|

|

(#13)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

11.07.2007, 11:54 PM

Let us know how it performs!

|

|

|

|

|

|

(#14)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

11.08.2007, 12:57 AM

Ran a pack thru it and it seems to work fine. Kind of slow, maybe near 40, but I think closer to 36-38 mph. I will try my radar gun on it tomorrow with a freshly charged pack and see how it does. Other wise it runs great, plenty of steering, and drives very well. Turns on a dime, you can really feel that it has a center diff! I may be thinking that it is slower than it is, due to how smooth and easy to drive it is! Are the diffs stock? I can feel that there is some heavier fluid in the rear, the front feels like grease or light oil. I may move up to a 22 tooth pinion as the motor is barely getting warm with this gearing.

|

|

|

|

|

|

(#15)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

11.08.2007, 02:14 AM

I think Mailman put some fluid in the diffs, so he'd have to say what's in them.

You could also try a smaller spur, like the 40t. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode