|

|

|

Crt.5 plastic spur |

|

|

(#1)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

Crt.5 plastic spur -

04.21.2008, 01:14 AM

Time for all of us to figure out how to get a plastic spur on the crt.5. I am sick of the noise the metal on metal gears make, and do not see any reason to stick with the metal spur.

I am thinking of taking a mod1 46t plastic spur and making it fit over the diff cup and attaching it to the steel spur. BrianG started to do this, but I am not sure if he had any success. I would also like to see a smaller version of mike's slipperential for the .5. I have a machinist who likes odd work, so I may have him make me something like that. Does anyone make a al diff cup for the crt.5? I would make the slipper setup work like the old maxx slipper, with the friction pegs and steel disks to clamp the spur. Any ideas or brainstorming are more than welcome, we should be able to get around this issue! |

|

|

|

|

|

(#2)

|

|

|

TEAM FUSION

Offline

Posts: 2,041

Join Date: Jul 2006

Location: Iowa... Hawkeye country

|

04.21.2008, 01:57 AM

I had a mfg. make a 32p gear for the CRT.5 about a year ago. But, between lazinessa nd delays on their part and the seeming lack of interest due to the hardened pinions I never had a batch of them made.

I can ask if they will still do it. They may not be interested now after not buying a batch at the time. They can't just do a few... it has to be at least 100 pcs for me to bother them with it again. Losi 8IGHT MM/Neu 1512 1900kv Kyosho 777 T4 MM 5700 B4 LRP XX4 MM 7700 old losi xxcr, MM4600 4s lipo 70mph+ |

|

|

|

|

|

(#3)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

04.21.2008, 07:50 AM

Any specific reason you went with 32p?

|

|

|

|

|

|

(#5)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

04.21.2008, 09:50 AM

I did try to come up with a setup that used the Kyosho 46T spur, but the CD mount would have to be moved (new holes redrilled) and the shaft shortened. Also, the outdrive cups used different dogbones. It's easily possible, but not without some custom parts.

|

|

|

|

(#6)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 405

Join Date: Jun 2007

|

04.21.2008, 10:57 AM

I'd like to run a plastic spur. The metal on metal draws a lot of attention on electric days at the local indoor track. I was hoping that Mike would have incorporated the plastic spur into his extended chassis. Maybe that will be a part of his version 2 extended chassis.

E-CRT.5 Stock - Sidewinder/4600/2s, buggy tires E-8ight - Tekin RX8 2000kv/4S E-8ight T- Tekin RX8 1700kv/5S |

|

|

|

|

|

(#7)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

04.21.2008, 11:25 AM

I have an idea that I will try out later. Does anyone know if there is an al diff cup made for the crt.5?

|

|

|

|

|

|

(#8)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

04.21.2008, 12:16 PM

Not sure about the Al diff cup, but a full 8th scale CD shouldn't be hard:

1) Drill two new mounting holes to allow room for the added length of the diff 2) Dremel out a cutout in the chassis for the spur, or raise the diff a couple mm. 3) Use different mounts, or mod the stock ones, since the stock CRT.5 CD bearings are an odd size (1mm smaller in diameter than typical 8th scale). 4) Mod the length of the dogbones or fab new ones up. 5) Out drive cups. I can see a couple options. A) Use 8th scale out drive cups on the F/R diffs if you can find ones the right post diameter B) Mod the stock bones so you can use them for the F/R diffs, but have the CD end use regular 8th scale size. |

|

|

|

(#9)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

04.21.2008, 11:05 PM

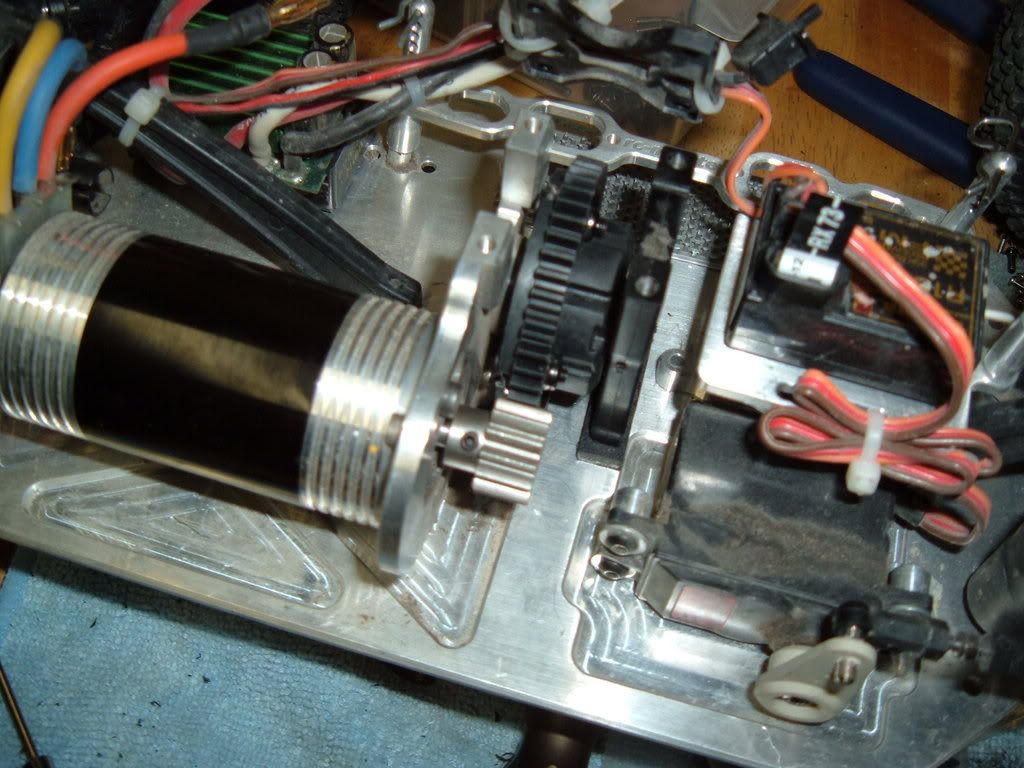

Interesting Brian, I may have found an easier way though...

Here we go, got bored and decided to find a decent plastic mod 1 spur to use. Found this in the tray of oddball spurs that I have laying around: 47t mod1 spur So I cut the inside out of the plastic gear until it fit over the diff cup. Then took the stock steel spur and ground off the teeth and the smoothed the cup side so that it was flat. Then I tried to drill the steel spur for holes to mount the plastic spur. That did not work, as the steel spur is super hard. I even tried to aneal the spur to soften it up, that did not work either. I ended up cutting slots with a fiber disk to place the screws. I clearanced the screw side for the countersunk screws and used nuts to hold the plastic spur on. Not pretty, but it works. I plan to clean it up with the dremel and dust it with some paint. Side pic makes the spur look crooked, but it is not. I plan to have my machinist turn the centers out of a few more of these spurs, as mine is slightly not right, a little bit of wobble side to side, but it runs true front to back. I then made some thin spacers to raise the bulks off the chassis, as the new gear placement does not fit in the chassis cutout. I like the further forward spur gear, as it gives more rooom to get the pinion on properly.    And a shot of it mocked up with the motor in the crt.5.

|

|

|

|

|

|

(#10)

|

||

|

Guest

Posts: n/a

|

04.22.2008, 01:13 AM

Quote:

so be sure to wear safety glasses. No joke I had one bounce off my forehead at very high velocity. so be sure to wear safety glasses. No joke I had one bounce off my forehead at very high velocity.What I did was take a spur. I think it was an ofna 47t steel spur. I stuck the spur in a drill and spun it against a grinder wheel to remove the teeth as evenly as possible. then drilled the holes to hold on a ofna 51t plastic spur. It worked very well. It looks very similar to what you have. |

|

|

|

|

|

|

(#11)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

04.22.2008, 01:23 AM

I had some tin coated bits, but cobalt one would have been better. I actually like the slots, as they let the screw angle a bit, which aids in getting the nuts on. Not much room to work with, I had to use pliers to hold the nut as I screwed it. (can't wait to hear what everyone thinks of that last sentence)

I used a bench grinder to grint the teeth off, then put a screwdriver shaft thru the hole in the spur and held it against the grinding wheel. I used another plastic handle to slow the spin of the spur, and that evened out the area that I ground the teeth off. It is almost perfectly round, and that does not really matter, as nothing touches that edge. |

|

|

|

|

|

(#12)

|

|

|

RC-Monster Mod

Offline

Posts: 6,597

Join Date: Apr 2007

Location: NJ

|

04.21.2008, 11:25 PM

Interesting - It might the pics but it looks a little wonkey...

|

|

|

|

|

|

(#13)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

04.21.2008, 11:27 PM

Yep, think I got too close with the camera. It is on there flat and does not wobble, must be an optical illusion!

|

|

|

|

|

|

(#14)

|

|

|

Guest

Posts: n/a

|

04.22.2008, 12:02 AM

i have the same problem when i run my hvmaxx motor in my crt.5 as well, i think its 2 times louder then my 9l, i just my try this as well, i had a thread awhile back on this but my first attemp didnt work out so i have been putting up with the noise, but my try again

|

|

|

|

|

|

(#15)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

04.22.2008, 12:21 AM

I like the robinson gear, if I had to do this agin I would use that gear as it already has the holes in it. I am going to get everything shimmed up right and give it a try tomorrow. Hope it works!

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode