|

|

|

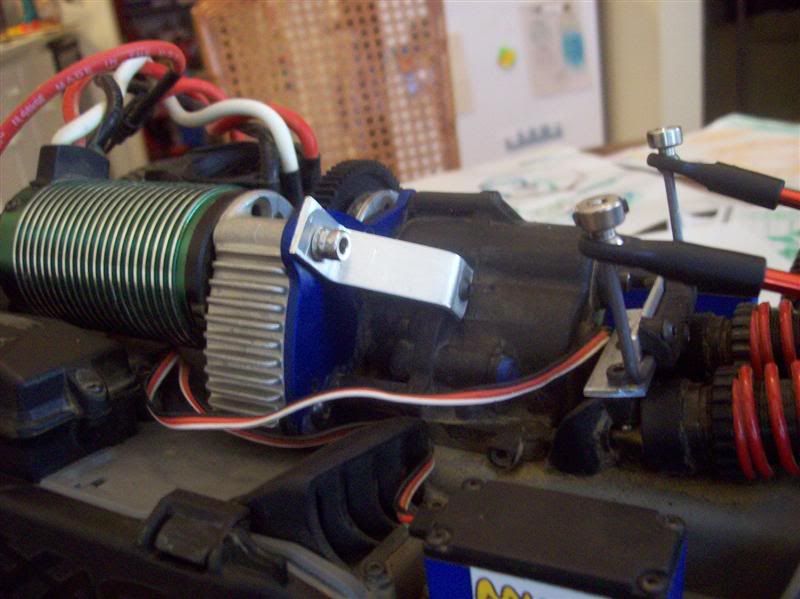

ERBE Motor Plate Brace |

|

|

(#1)

|

|

|

Fat Kid Engineering

Offline

Posts: 3,634

Join Date: Jun 2009

Location: Hot as Hell West Central Coast Florida

|

ERBE Motor Plate Brace -

08.18.2009, 04:07 PM

I don't know about anybody else but I've wasted a few spur gears the last 8-10 months and finially decided to remedy the situation. Landing very large jumps or botched landings the motor mount plate will flex and chip a tooth or two of the spur gear and heres a simple easy fix. I will be testing this mod Weds.

All thats needed is a P2 pushrod and some hardware and a 1/8" bit and drill.

|

|

|

|

|

|

(#2)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

08.18.2009, 04:56 PM

Looks good, I have always wondered about the super thin motor plates on the traxxas stuff. Maybe if they were made of High Strength Steel, but al at that thickness is not really the optimum material. Some redesign or bracing from traxxas would be a good idea.

|

|

|

|

|

|

(#3)

|

|

|

Fat Kid Engineering

Offline

Posts: 3,634

Join Date: Jun 2009

Location: Hot as Hell West Central Coast Florida

|

08.18.2009, 05:29 PM

I'm hearing ya, If this fails to hold up I will make one from a steel. Don't want to double up the AL plate, to many extra mods then.

|

|

|

|

|

|

(#4)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 4,236

Join Date: Dec 2007

Location: Cape Cod, Mass.

|

08.18.2009, 07:26 PM

Just plain sexy!

2. MBX-5T 1520, MMM ON 5S 3. MBX-5 ONROAD CONVERSION 1515, MMM ON 5S 4. MRX-3 ON ROAD CONVERSION 1512, MMM ON 6S 5. TEN T 2650 T8, MMP ON 3S |

|

|

|

|

|

(#5)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 67

Join Date: Jul 2009

Location: Edmonton, Alberta

|

08.18.2009, 08:10 PM

I like it... I look forward to hearing how it works.. I like bracing:

|

|

|

|

|

|

(#6)

|

|

|

Guelph, Canada, eh!

Offline

Posts: 1,083

Join Date: Sep 2007

Location: Guelph, Ontario, Canada

|

08.18.2009, 11:55 PM

That stock motor plate is very flexible, it is some cheap aluminum that is barely 3 mm thick like the aluminum chassis of a nitro Revo. I tried doubling up the motor plates and they still bent. The motor/mount is heavy and they are hanging from that plate. I went back to that 6 mm thick carbon fiber plate I made and it is much stiffer and stronger but CF does not dissipate heat like aluminum does so my motor runs 10 degrees hotter. That rod looks like a good solution. The best would be a 4 mm motor plate machined from billet aluminum. Like 7075 T6 aircraft grade stuff. Strength, stiffness, lightweight and heat dissipation. While you're at it, machine the motor mount also from that same billet aluminum with larger fins for better cooling. Add a brace similar to what you did on top of that and that motor wouldn't budge at all.

|

|

|

|

|

|

(#7)

|

||

|

Fat Kid Engineering

Offline

Posts: 3,634

Join Date: Jun 2009

Location: Hot as Hell West Central Coast Florida

|

08.19.2009, 10:50 AM

Quote:

Sooner or later someone will come out with a CNC'd plate, hopefully ? |

|

|

|

|

|

|

(#8)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,884

Join Date: Jul 2009

|

08.19.2009, 01:02 AM

I'm surprised no one makes a sturdy aftermarket mount for the E-revo. Seems like it would be a no brainer for the aftermarket companies.

Nice work Jeff! |

|

|

|

|

|

(#9)

|

|

|

i pwn nitro

Offline

Posts: 769

Join Date: Nov 2008

Location: with ur GF

|

08.19.2009, 05:14 AM

the E-revo motor mount might be low CG and everything...but i run the E-maxx setup (motor over tranny) and it NEVER bends and i am shocked at how long my spur gear has lasted!!

this spur gear has about...geez....10 race meets and about 5 hours bashing on it and it's STILL going!!!  but everyone running the E-revo style mount at the club is stripping spurs and so are the guys here....wonder if the higher CG is worth it?? the porthole from the noob world an here has been opened!! that's how i got in. |

|

|

|

(#10)

|

||

|

Fat Kid Engineering

Offline

Posts: 3,634

Join Date: Jun 2009

Location: Hot as Hell West Central Coast Florida

|

08.19.2009, 10:46 AM

Quote:

HotRacing makes 2 styles and they are nice looking, but I trust those A-holes as much as that Integy garbage. http://www.hot-racing.com/?c=431 |

|

|

|

|

|

|

(#11)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,884

Join Date: Jul 2009

|

08.20.2009, 03:26 PM

Quote:

|

|

|

|

|

|

|

(#12)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

08.20.2009, 03:40 PM

Are you running the stock body?

|

|

|

|

|

|

(#13)

|

|

|

Fat Kid Engineering

Offline

Posts: 3,634

Join Date: Jun 2009

Location: Hot as Hell West Central Coast Florida

|

08.20.2009, 04:50 PM

|

|

|

|

|

|

(#14)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

08.21.2009, 08:13 AM

OH I see. Right, just several of the guys at the Traxxas forum where have problems with there thin stock bodies collapasing hitting inside componants. Resulting in stripped wires, stripped spurs, bent motor plates. Definently not your problem. Let us know how the bracing works out.

|

|

|

|

|

|

(#15)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

08.23.2009, 03:31 PM

Here is what I just tried:

I liked Bondonutz's idea of bracing the motor that he posted above, but I was concerned about bracing it to the chassis. If the chassis bends, what type of pressure is that going to put on the motor and gears? So I wanted to keep it simpler and eliminate the (possible) variable of chassis flex. The brace I installed definitely cuts down on the amount of flex of the blue motor plate significantly when I push on the motor. Now, the most of the motor movement (which is reduced from before installing the brace) is due to the gray part of the motor mount (attached directly to the motor) separating slightly from the blue motor plate. So, to eliminate this, I would have to do something like Bondonutz did - or figure something else out. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode