|

|

|

Krawlin's Mill Review & Upgrades |

|

|

(#1)

|

|||||||||||||||||||||||||||||||||||||

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

Krawlin's Mill Review & Upgrades -

11.24.2010, 04:46 PM

For those of you who follow my MGT build thread you probably know I recently purchased a mini mill. For those of you who don't follow my build thread, I recently purchased a mini mill.

Anyway, long story made short, I've gotten it all setup, and have been using it ALOT since then. I figured making a thread like this (review & upgrades) will help others when considering buying a mini mill. Here is a link to the mill I purchased - https://www.littlemachineshop.com/pr...ory=1387807683 Anyway, long story made short, I've gotten it all setup, and have been using it ALOT since then. I figured making a thread like this (review & upgrades) will help others when considering buying a mini mill. Here is a link to the mill I purchased - https://www.littlemachineshop.com/pr...ory=1387807683So here are some of the key details about the mill I bought -

Something also important to note. The following mills, including the one from LittleMachineShop.com, all come from the same factory. Sadly, made in China, but according to the comparison chart from LittleMachineShop.com, all have about the same general quality, but some have better features (and price points) than others. My personal opinion after comparing a Harbor Frieght mill (in person) to my LittleMachineShop.com mill, the LMS mill is of a higher quality. Take a look at this comparison chart, gives the stats on all of these similar mills - (see next post for the chart, damn this 10,000 character limit!!!) Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

||||||||||||||||||||||||||||||||||||

|

|

|

(#2)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

11.24.2010, 04:52 PM

(first half of comparison chart due to character limit)

Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

(#3)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

11.24.2010, 04:53 PM

(second half of comparison chart due to character limit)

Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

(#4)

|

|

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

11.24.2010, 04:53 PM

"LittleMachineShop.com HiTorque Mini Mill is the best in its class. It has the most power, most torque, and a larger table than other mills in its size range.

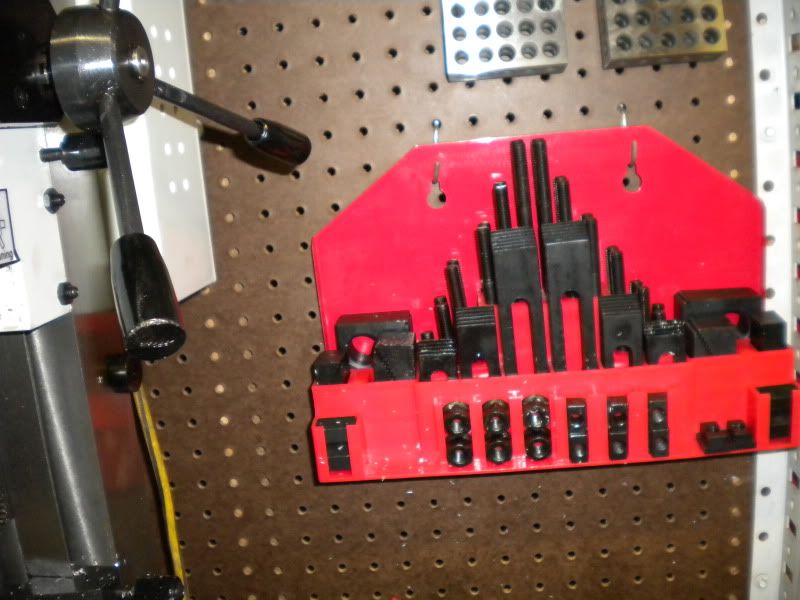

The 500 Watt (0.67 hp) brushless spindle drive motor provides tremendous low end torque. And you can vary the speed from 50 RPM to 2500 RPM continuously. There are no gears to shift. And, with no gears, the HiTorque Mini Mill is the quietest in its class. The large mill table provides 50% more table area than other mini mills. It also has 30% more travel in each direction. The resettable feed dials allow you to zero them at any point. Grizzly Industrial, Inc. sells the Grizzly model G8689 mini mill. The Grizzly mini mill has a 3 Morse taper spindle. It comes with two 3 Morse taper collets; a 3/8 inch collet and a 1/2 inch collet. Harbor Freight Tools distributes the Central Machinery model 44991 mini mill. The Harbor Freight mini mill has an R8 spindle. Micro-Mark carries the MicroLux model 82573 mini mill. The Micro-Mark mini mill has a 3 Morse taper spindle. The MicroLux mini mill has one unique feature; the table feed dials both advance 0.050 inch per revolution. On all the other mini mills the dials advance 1/16 inch per revolution. The 0.050-inch per turn is easier to use than the 0.0625-inch per turn of the other mini mills. Micro-Mark will have you believe that the other mini mills have metric dials, but they do not. Micro-Mark also carries the MicroLux model 84630 R8 mini mill. This mini mill is similar to their other mini mill except it features the 500 watt brushless DC drive system. Homier Mobile Merchants sells the Speedway mini mill model 03947. The Homier mini mill has an R8 spindle. ToolsNow.com (Cummins Industrial Tools) sells the mini mill model 7877. The ToolsNow mini mill has an R8 spindle." Knowing everything above really helped influence my decision. Now if I had the garage space (and a good excuse  ) to purchase a large Bridgeport mill, I would have gone that route in a heartbeat, but since I have neither, this small mill is perfect for me. Its very quiet, it doesn't take up much space, has plenty of power, and great capabilities to do what I need it to do. So far, I love it. Here is a list of some pro's and con's I have found thus far with this mini mill. ) to purchase a large Bridgeport mill, I would have gone that route in a heartbeat, but since I have neither, this small mill is perfect for me. Its very quiet, it doesn't take up much space, has plenty of power, and great capabilities to do what I need it to do. So far, I love it. Here is a list of some pro's and con's I have found thus far with this mini mill.Pros--- - It's Brushless!!! - Great specs on the table travel - Powerful - Quiet - Doesn't arrive slathered in that nasty red assembly grease, just a light coating of oil and a mild grease to prevent rust during shipping - Good price point at $650 - the X-Axis gib is easy to adjust, and the hand wheel has maybe a thousandth of play, if that, and turns very smoothly. - Even when milling steel, it remains very quiet. The motor doesn't even break a sweat, and after a couple hours of a machining newbie (me) playing around with it, the motor was only warm to the touch. - 12mm T-Slots, a common size for most mini mills, so clamping kits and accessories that bolt to the table are easy to find, nothing specialized needed other than a clamping kit meant for 12mm t-slots. - R8 taper spindle is much more forgiving than #3 Morse taper, just unscrew the draw bar a bit, tap it lightly with a hammer, and your collet/endmill holder will drop enough just enough to easily remove the bit you are using. - Comes with a small tool kit with everything you need to adjust the mill. Cons--- - The Y-Axis gib is difficult to adjust, and easy to over-tighten it. - The Y-Axis has a bit more play than I would like, as in, I can turn the handle wheel about 4 thousandths without the table moving. - Each complete turn of the hand wheel moves the table 1/16th of an inch (.0625), would rather have it so each turn of the hand wheel moved the table .050, would be much easier to do alot of the math this way. - No metric option? - The fine feed for the Z-Axis has a good bit of play in it, maybe it just needs to be better lubricated though. - Probably being OCD, but the axis locking levers, particularly on the Y axis, are in dumb places, where you can screw it in about 2/3 of a turn, then have to pull the knob back and twist the opposite way to reset it on the locking bolt so you can turn it the rest of the way to lock it. Here are some pictures of it, as well as an old T-Maxx chassis that became a practice part for my first time using the mill -      My set of endmills, 2 and 4 flute  Clamping kit  All cleaned up, small bottle of Pepsi for size reference  Stay tuned, will be posting about my first upgrade pretty soon, a solid mounted compressed air shavings removal system. Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

|

|

|

(#5)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

11.24.2010, 05:24 PM

Very Nice setup! Can I put in orders now ;)?

R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#6)

|

|

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

11.24.2010, 06:22 PM

Thanks Ben! Not sure if I can say yes or no to that on here, RCM-Mike might not like that. You have my AIM though.

Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

|

|

|

(#7)

|

|

|

roofles.

Offline

Posts: 1,982

Join Date: Oct 2008

Location: Woodland Hills, CA

|

11.24.2010, 08:48 PM

Holy research batman!

Nice mill, I like. Video! |

|

|

|

(#8)

|

|

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

11.24.2010, 09:04 PM

Thanks!

I'll probably make a video tomorrow, going to put a cup type wire brush in it and see if I can get that circular brushed look on my spare MGT chassis. Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

|

|

|

(#9)

|

|

|

RC-Monster Square Tube

Offline

Posts: 1,367

Join Date: Jun 2008

Location: CNY

|

11.24.2010, 09:47 PM

Nice breakdown!

Backlash is an absolute fact of life, the only way to eliminate it would be to use an NC type ballscrew, and that would quadruple the price (at least). .004" backlash is VERY respectable, I deal with machines with an average of .050" and some nearly .1", the older, the worse. I agree with your gripe about the .062"/turn, that really should be .050, the standard for larger equipment is normally .1"/turn. I would work around that by doing your layout & setup according to the .062", kind of a pain but you're stuck with that.... You'll have no lack of uses for it, congrats on the purchase. My Videos: http://vimeo.com/user2236105/videos |

|

|

|

|

|

(#10)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

11.24.2010, 11:17 PM

So how much did everything come to? Ie vice, tooling, etc?

Been looking at these a bit and was looking at the next size up (grizzly 704 equiv.) Had head good things about the mini mark, but also that getting a dro will solve any weird measuring due to the .065 on the other machines. Like that size tho..looks easy to find home for it. |

|

|

|

|

|

(#11)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

11.25.2010, 12:37 AM

Quote:

And actually after doing a quick search, I discovered there is a kit to convert my machine over to .050'' per turn, https://www.littlemachineshop.com/pr...ory=1687114045 , so I'll definitely be purchasing that pretty soon. Quote:

Price for the mill was $763 shipped, Mill without shipping is $649.95 Tooling ended up being $316 shipped. Total with mill and tooling is $1079 shipped. Still need more tooling though. Seems like its one of those never ending things, where you can never have enough tooling for a mill, because one day you will need to use that one special bit, and then it will sit for another year before it gets used, but if you don't have it you're screwed.  Here is a price list of the tooling I bought -

And that starter kit included a clamping kit, edge and center finder, t-slot cleaner, parallels, and 1-2-3 blocks. Also, I wouldn't recommend the vise that I bought, seems kind of low quality, and the degree markings and alignment mark seem poorly cut/laid out. Lots of better vise options out there. I will edit the first post and put a link to the mill in there, I forgot to add it when I made the post. https://www.littlemachineshop.com/pr...ory=1387807683 I looked up that Grizzly 704, that thing looks awesome, now I'm getting buyers remorse and wish I had gone with that.

Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode