|

|

|

(#16)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

12.18.2007, 03:35 AM

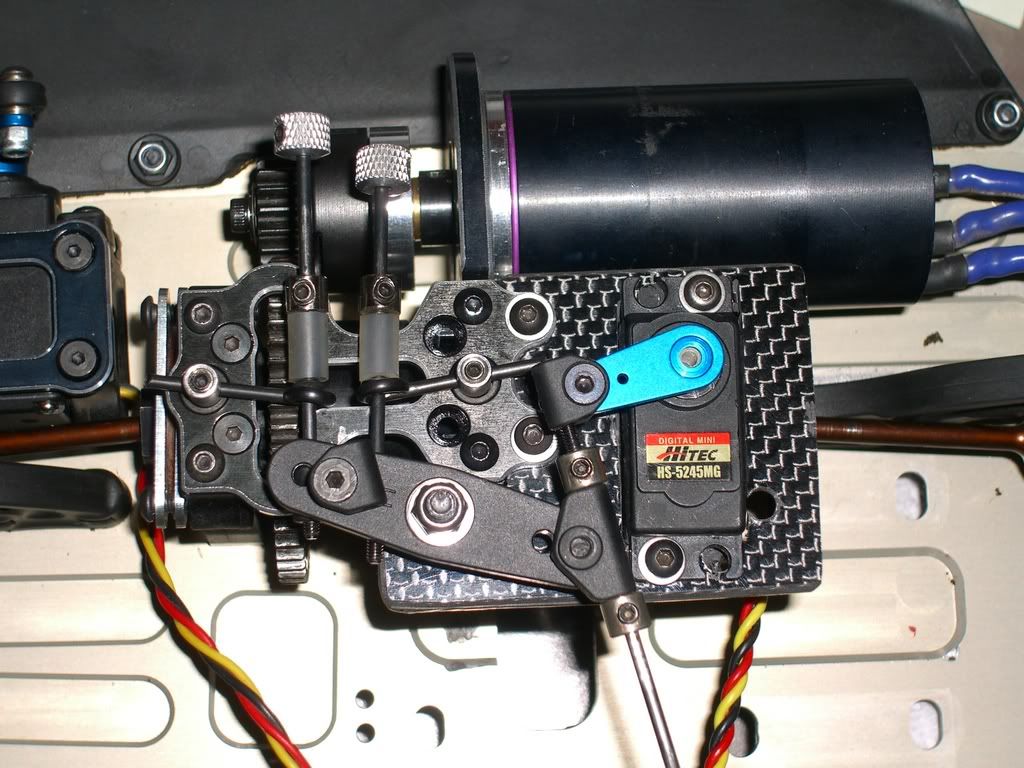

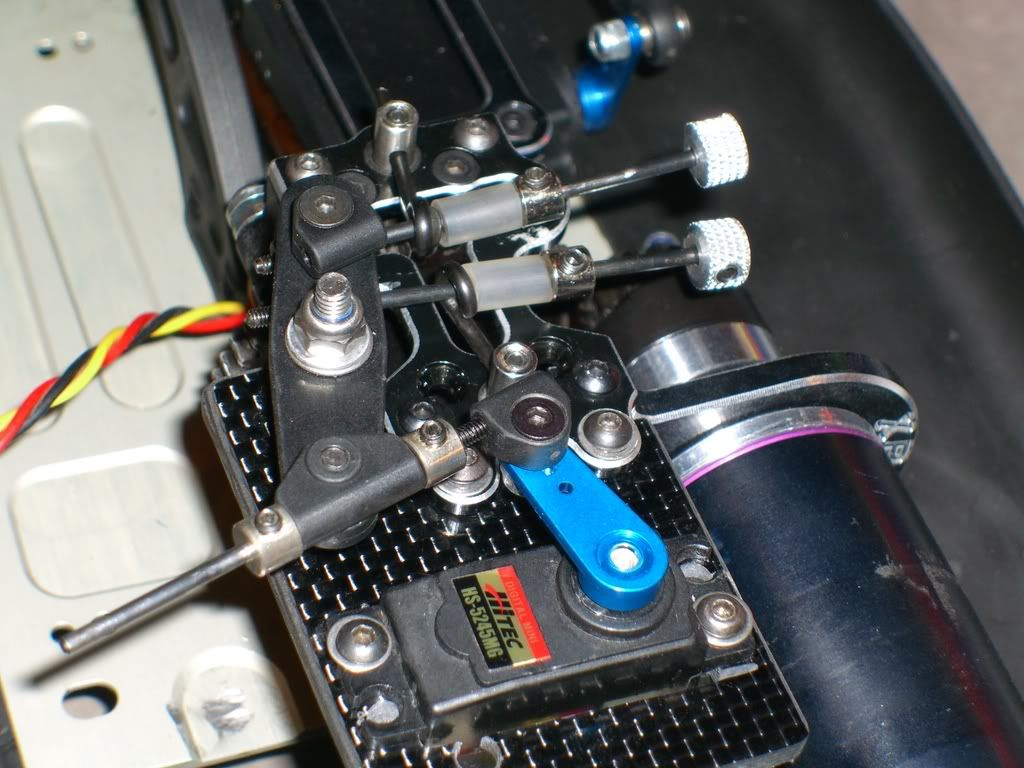

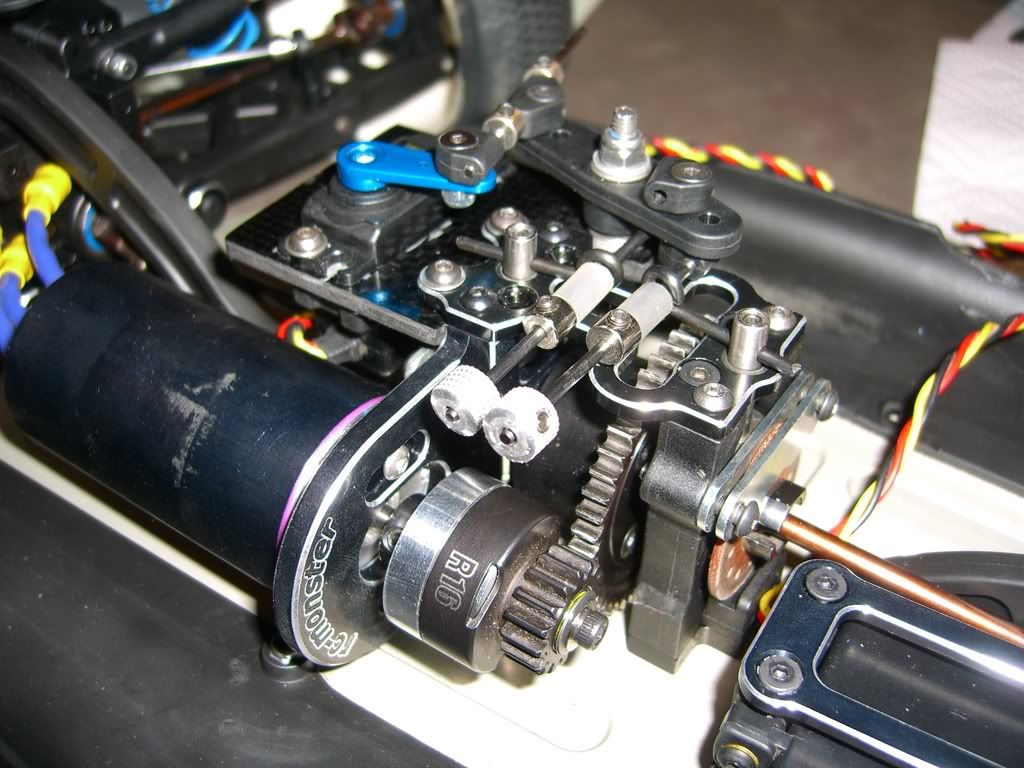

Little update. I think I have the brake servo sorted out. It still needs to have some of the linkages shortened to neaten it all up and I am still missing some screws and using less than ideal screws in other areas just because it was what I had at the momnet, but I just assembled it to test the fit up and see if the mini servo was going to be powerful enough. I'll clean it all up later with the proper fasteners and correct length linages and all.

The goal was to come up with something that would be a compact setup that would take as little valuable chassis space as possible and add as little weight as possible. Again... Thanks for the suggestions Mike!! It can hold the tires locked up when I drag it across the carpet so that should be enough to lock up the tires on any dirt surface. Something I really like about it is, the whole assembly will lift right off for maintenance of the diff just by removing the screws that take the diff top plate off. It all just stays together as one unit. It also gives me easy access to the thumb screws for adjusting brake bias. It should be just as easy to dial in the brakes as it is on a conventional nitro setup. I made a carbon fiber servo plate that mounts to the center diff top plate and mounted the mini servo into it. I then made a lever to attach the the linkages to and used it to reverse the pull direction so I could pull the brake cams in their natural direction. I'm also using the lever arm to generate a little more effective torque by mounting the servo linkage to the farthest out hole on the lever and mounting the brake linkages to a hole a little closer in to the pivot point. I used .125 in. CF plate and it all seems very sturdy. I guess I won't really know until I land a few jumps and crash a few times, but I think it will be robust enough to withstand the abuse. At least I hop it will. Anyway here are a few pictures. Its tough to explain and the pictures will do a much better job.

to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#17)

|

|

|

RC-Monster TQ

Offline

Posts: 703

Join Date: Mar 2005

|

12.18.2007, 07:32 AM

The HS5245 has the perfect size/weight/power for bashing but for racing, I've been using the HS81MG for a few years now. Its all about leverage

I am also ONLY using rear brakes. You still get some front braking power from the center diff but not much (depends on how heavy the diff fluid is) I also picked up a Electrik-Clutch adapter. What type of clutch shoes and springs are you using? I plan to run without the clutch springs so that the shoes will engage sooner. The Flashlight Strikes Again... |

|

|

|

|

|

(#18)

|

|

|

RC-Monster Gold

Offline

Posts: 281

Join Date: Oct 2006

|

12.18.2007, 08:37 AM

I'm running carbon shoes. Half a dozen packs through and no issues as of yet. I think my springs are a bit heavy as well and was considering going to lighter springs. I think I may try just removing one first to see how that works.

|

|

|

|

|

|

(#19)

|

|

|

Guest

Posts: n/a

|

12.18.2007, 09:56 AM

VERY cool. Maybe you guys can make "kits" of all that one needs to make it fly on popular kits...

DM |

|

|

|

|

|

(#21)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,824

Join Date: Apr 2005

Location: largo fl

|

12.18.2007, 12:11 PM

That looks really good.

|

|

|

|

|

|

(#22)

|

||

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

12.18.2007, 01:09 PM

Thanks for the comments guys.

Kits are for the pros like Mike or Tekno to deal with. I think Mike is working on his own (probably much better) Elektri-Clutch setup in a 1/8 buggy to see how it works. If it does work well, I'm sure there will come a time when sombody makes kits, just like the direct drive setups now. But at this point I havent even seen a 1/8 with a fully functional clutch setup in it yet, so who knows if there is even a benefit to it yet. This may all be just a big elaborate waste of time. Quote:

I'm using the M2C 3 shoe Revo clutch setup with the .9 springs and Med. shoes. I bought this kit http://www.m2cracing.com/product.sc?...&productId=175 and turned the flywheel down to the same diameter as the clutch bell because It was in the way and I couldnt make it fit anywhere. to make it... or break it... Silent...But Deadly |

|

|

|

|

|

|

(#23)

|

|

|

RC-Monster TQ

Offline

Posts: 703

Join Date: Mar 2005

|

12.19.2007, 12:57 AM

jhautz,

I made a custom clutch back in January and it was definetly not a waste of time. Here's the link for those that don't remember or never saw it: http://www.rc-monster.com/forum/showthread.php?t=5265 Anyway, I gave up with the project because the Losi 8ight did not have enough room for batts with the configuration I had as well as the motor temps were pretty high. I never tried running the shoes in reverse though. I'm going to give this a try again with the Electiclutch because this adapter seems a little more freindly than my custom setup. I guess I should have put a patent on it back then :) The Flashlight Strikes Again... |

|

|

|

|

|

(#24)

|

|

|

Guest

Posts: n/a

|

12.20.2007, 06:55 PM

have you put any time on this set-up yet, how is it working??

i just won a xray truggy and am getting ideas |

|

|

|

|

|

(#25)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

12.20.2007, 07:58 PM

No... No its not running yet. I have a couple little parts that ordered and I'm waiting for still and I need to get a battery tray worked out and the whole thing wired. I doubt I will spend any time on this untill after after the new year.

I'm pretty much booked from now untill January.  Really sucks cuz I'm die'n to see how it works as well. Really sucks cuz I'm die'n to see how it works as well.

to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#26)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

12.20.2007, 11:52 PM

I like the conversion, looks really good!

I am also going to try out the clutch setup in my yusa rally (inferno gt). I modded a 4tec 2 speed clutch bell to get the correct spacing for the 2 speed spurs. I am also stuck waiting on parts, and I need to make a custom motor mount too. |

|

|

|

|

|

(#27)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 141

Join Date: Oct 2006

Location: Sunny SoCal

|

12.21.2007, 04:59 PM

Very interesting a clutch could also help eliminate cogging by reducing the load at start on the motor?

Q does the adapter have a STD 2 pin configuation so you can try different style clutches? I would be very interested in trying this out in my CRT with the 1515 Neu and MM esc to see if it will eliminate the cogging issue? I was looking at your pic and how you used a bell crank to work the brakes and it seemed a little complicated you can eliminate it by redrilling the holes on the brake cam and moving the brake arms you can push 1 side and pull the other see pic. :) |

|

|

|

|

|

(#28)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

12.21.2007, 05:21 PM

The adapter is just a shaft like a nitro engine output shaft that goes on the motor shaft with a set screw like apinion gear. You can mount whatever traxxas compatable flywheel you want on it. Mine happens to be 3 pin/shoe style clutch from M2C, but a standard Revo 2 pin/shoe flywheel also works. Mike sells a small diameter 2 shoe traxxas flywheel for this made to work in this type of application.

As far as the cogging... The Tekno RC revo conversion uses this setup with a MM and a Neu in a Revo and they have poven it to make a the cogging issue a non-factor. But to me I still wish Castle would fix thMM software. They have been saying they will ever since the MM was released. Typical CC... All talk and no action. I like the push/pull idea IBJammin... I did think of pushing one side and pulling the other but not in that simple config. I didnt go the push pull route cuz I was hesitant to try pushing one of those skinny little rods. I wasnt sure if it would be consistant. I will probably stick with this setup cuz its done already and it seems to work pretty well. I have 4x7 bearings in the middle of the cam lever riding on a 4mm screw and it is very smooth. When I disconnect the linkages and spin the lever it spinns like a wheel with very little drag so I dont feel like I'm loosing much energy in the mechanics. Although your idea would probably be more efficiant even if its just a little. I'll make that plan B. If this doesnt work out. It would be an easy change to make. Thanks for the sugestion

to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#29)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 141

Join Date: Oct 2006

Location: Sunny SoCal

|

12.21.2007, 07:29 PM

I too am tired of waiting for the elusive MM update and this might be the answer I need to look into it and see how hard it will be to get the disc brakes back in there and fit the longer clutch unit in my CRT? I wasn't very happy with the motor braking anyway and wanted to put the brakes back in for more consitant braking and to get the brake bias back. :)

If you dont like to push it you can stack them both on the same side and pull them or use 1 rod for both brake arms? no prob I understand if it works why change it.

|

|

|

|

|

|

(#30)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 130

Join Date: Dec 2006

Location: Oslo

|

12.21.2007, 08:39 PM

Hi

where did you buy the clutch? |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode