|

|

|

(#31)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 135

Join Date: Oct 2007

Location: Munich, Germany

|

02.01.2008, 02:59 PM

So here's a short video just to show you that cogging isn't existing, even when i drive as slowly as i can: http://picasaweb.google.de/Brushless...87508891729186

|

|

|

|

(#32)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

02.01.2008, 03:10 PM

Sweet, that is as smooth as ya like. I cant do that with my sensored inrunner system, so multipole outrunners have a definate advantage so long as the esc is good.

|

|

|

|

|

|

(#33)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.01.2008, 03:25 PM

OMG!

That's the smoothest I've seen! Very Good! I'm becoming more and more convinced on the Kontronik line. That's a different startup routine in the software. Works great! |

|

|

|

|

|

(#34)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 135

Join Date: Oct 2007

Location: Munich, Germany

|

02.01.2008, 03:33 PM

Yeah, it's running really smooth, it think also this is because the Kontronik ESCs have a great car software and are choosing the perfect motor timing automatically.

|

|

|

|

(#35)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,139

Join Date: Sep 2006

|

02.01.2008, 04:03 PM

Kontronik makes a really good controller. I hope the new Jive controllers will come out with the car mode.

|

|

|

|

(#36)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 135

Join Date: Oct 2007

Location: Munich, Germany

|

02.06.2008, 09:58 AM

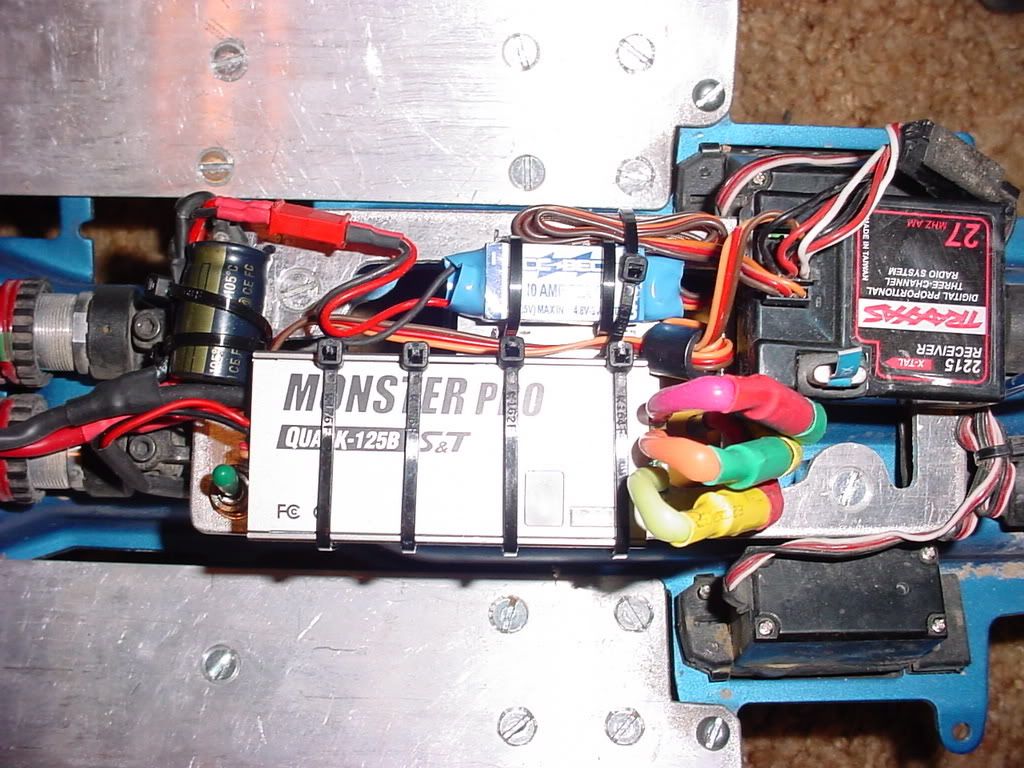

I recieved my Integy diffcases, hardened gears and Maximizer diffcups today:

Yesterday i crashed with 30mph into the tire of a truck and it killed my RPM rear bumper, my wing, my wing mount and my rear body mount....  Now i'm waiting for my spares from liquidrc.... |

|

cool |

|

|

(#37)

|

|

|

speedfreak.dk

Offline

Posts: 15

Join Date: May 2007

Location: denmark copenhagen

|

cool -

02.06.2008, 03:59 PM

i have exact same outrunner :)

i stuffed it in a homebuildt car a little bigger that the pede with rwd and the outrunner coupled direct to diff tru a dogbone.. only testet on 5 cells so far, seeing that it can pull your big truck no wonder im only peaking at 17A in my truck :) gues i will put it in something bigger tires on it then :) nice build |

|

|

|

|

|

(#38)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.07.2008, 10:24 PM

Those are some VERY nice diffs you have there BL!

Any updates? Do you feel like your setup would work well with even higher gearing? Your current gear ratio is 4.6:1 total. I am switching my Direct Drive to Diff Revo from 4.3:1 diff ratio to 3.3:1 diff gear ratio. I'm hoping it will work without cogging. I've also been thinking about buying a Kontronik ESC like yours.

|

|

|

|

|

|

(#39)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 135

Join Date: Oct 2007

Location: Munich, Germany

|

02.08.2008, 04:01 AM

I'm still waiting for my parts from liquidrc and i'm looking for someone who is interested in my CrimeFighters that i can order the Phaltlines. According to Brians calculator my total ratio is 4,9!? I think my setup would also work well with higher gearing. Is your motor cogging only when it is under load in your vehicle or is it also cogging if you let it spin freely?

I can only recommend you buying a Kontronik ESC, you won't be disappointed. |

|

|

|

(#40)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.08.2008, 02:47 PM

Quote:

Let me start at the beginning with my build. It has changed and evolved alot since the start of it. I set my Revo up Direct Drive to Diff. It doesn't have a transmission. I installed a AXI 4130/20 outrunner. It's a pretty big one. Using a Quark 125amp Monster Pro. I noticed it would cog about 50% of the time on startup from a standing stop. If it was rolling at any speed, there was no cogging. I was using the stock diffs with a ratio of 2.85:1. This is when things began to change. I replaced the stock diffs with a pair of RCM's Revo diffs and went with the truggy gear ratio of 4.3:1 The cogging went away and things were looking great. I then rewound my 4130. Factory wind was 20 turns with a Delta Termination. The custom wind that I chose is a 4 turn Wye termination using 6 parrallel strands of 22awg wire. I dropped so many turns because I wanted a higher kv rating. It is now in the 550 to 600kv range. The factory Delta wind was 305kv. I went with the Wye Termination because 8 poles are energized at any given time instead of 4 as with the Delta termination. Wye has 1.73 times less kv, BUT makes 1.73 times more torque. This is the reasoning for the drastic change in the number of turns. I also raised it's amp capacity by using such large winding wire. By adding AXI's motor fan to the endbell, it runs VERY cool and makes tons of power! I have some vids posted if you would like to check it out. The Wye wind starts better. There is no cogging. but here's where the problem sets in. The 4.3:1 truggy gears are spiral cut gears. The pinion tends to load the bearings as if they were thrust bearings. They can't hold this load since it isn't a side load. In less than 2 packs, it will punch the inside race right through the pinion bearing. I know my shimming is correct. I'm going to go back to the regular cut gears. They are 3.3:1 ratio. Still lower than stock, but my fear is startup cogging will come back with the Quark. This is where I will probably go with the Kontronik ESC that you are using. It looks like it has a better startup routine than the Quark for this application. I also like the fact that I can bump on up to 8S Lipo if I want to.

|

|

|

|

|

|

|

(#41)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 135

Join Date: Oct 2007

Location: Munich, Germany

|

02.08.2008, 03:52 PM

Ok, now i understand your problem. I've already seen your Revo, the motor is really large. I don't think that you should get much more cogging if you go up to the 3.3:1 ratio. Have you already added some caps to your Quark? I think that they would help to reduce cogging.

|

|

|

|

(#42)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.08.2008, 04:07 PM

Quote:

In the beginning, I added a huge bank of Capacitors. LOL Now I just have 1 additional Novak 2700uf cap. It seems to work great as the Quark 125 runs very cool.

|

|

|

|

|

|

|

(#43)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 135

Join Date: Oct 2007

Location: Munich, Germany

|

02.08.2008, 04:22 PM

You are using the stock Traxxas radio!? Don't you have range issues or something like that?

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode