|

Laser cut carbon fiber? |

|

|

(#1)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

Laser cut carbon fiber? -

05.01.2009, 08:57 AM

Hi guys,

I'm currently working on a little project with Carbon Fiber that will require some custom cuts (a chassis to be specific) and the only 'CNC machine' I may have access to, is a 120 watt laser. I would like to know your person experiences with this method of cutting... The pros and cons. The Carbon is 4.3mm think and they are quite a few detailed cuts for upper and lower plates. Any help will be appreciated Alien |

|

|

|

|

|

(#2)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

05.01.2009, 05:59 PM

Lazer cuts tend to be more precise due to the smaller cutting 'tool' diameter, though what thickness you can do is another question. I would suggest doing some test cuts of various intricate shapes on a scrap piece of material to see if it leaves a clean finish/edge like you desire. One thought is that the heat of the lazer will either leave a nice clean edge that seels itself, so is less prone to splintering, or it may leave a slightly singed edge- only one way to find out, unless there are websites that offer the same service so could advice you on what to expect.

|

|

|

|

|

|

(#3)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.01.2009, 08:44 PM

Hey Neil, thanks for the suggestions man... I will get some tests done to see how the Carbon reacts to the laser.

Alien |

|

|

|

|

|

(#4)

|

||

|

Second place is the first loser!

Offline

Posts: 899

Join Date: Sep 2008

Location: Utah

|

05.02.2009, 12:44 PM

Quote:

hey dude, DONT USE LAZER TO CUT CARBON. i have been building some custom carbon chassis over the past few months and i initially tried laser to cut them out as it was going to save me money. the cuts were straight and everything but what happens is the laser melted the epoxy ever so slightly along every cut made. this caused the fabric to be frayed really bad along every cut and the the part looked like shit. also, the frayed fabric gets in your skin like fiberglass and is horrible to try to work with after that. i just use a CNC shop to cut all my carbon now and it is 10x better. save yourself the trouble. idk, i have heard of people using laser to cut carbon successfully so i dont know if the piece i had cut was inferior or what but since then i have used the same carbon cut on the CNC for my 1/8 brushless truggies and have been racing with them for weeks without any issues. and this is only 3mm carbon so i would say it is decent carbon to hold up to the abuse i have given it. pm me if you have any other questions. i have been working with custom carbon stuff for the past 6 months and can maybe help you out with any more questions. Losi Ten-T SCT conversion Neu 1512 1y |

|

|

|

|

|

|

(#5)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,139

Join Date: Sep 2006

|

05.02.2009, 12:56 PM

Has anyone thought about waterjet?

|

|

|

|

(#6)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.02.2009, 01:15 PM

Quote:

Hey Ryu, Thanks for sharing your experience man, I'll have to go search for someone here in Jamaica with the appropriate CNC machine to get this done right then... The same company with the laser might have one. The other problem is, if I do find them, it's hard to convince the shop to try a material outside of the list they may already used for their business. Hi Lutach, no waterjets here so far  ... So that's not an option for me right now. ... So that's not an option for me right now.Alien |

|

|

|

|

|

|

(#7)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,139

Join Date: Sep 2006

|

05.02.2009, 01:36 PM

Ok, all I know about carbon fiber and high heat is that carbon fiber burn pretty good. I've heard of people using a CNC machine and placing the CF under some sort of liquid to avoid all the harmful dust. If the same can be used with the laser then it might work.

|

|

|

|

(#8)

|

|

|

Second place is the first loser!

Offline

Posts: 899

Join Date: Sep 2008

Location: Utah

|

05.02.2009, 03:53 PM

i started out using a dremel tool with carbide tungsten bits to make my own carbon parts. then i found a CNC shop to do stuff. just make sure they use carbide tungsten bits. all other bits melt. also, the dust is extremely harmfil to breathe so you need to wear a mask when doing work with carbon. and i think it is better to run the bit at the slowest speed possible that still cuts efficiently. going faster only melts the bits or the carbon. i have found a slow speed cuts much better.

as for waterjets i havent tried it but i have heard that it also frays the carbon resulting in a very ugly part and one that most likely cant be used. CNC is the way to go but may require some experimentation on your part. there are some CNC shops that work with carbon all the time and really have a good system down of how to do it best. i have yet to find one locally but look around as i know there are shops that specialize in working with carbon and have already gone thru the trial and error. Losi Ten-T SCT conversion Neu 1512 1y |

|

|

|

|

|

(#9)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.02.2009, 05:10 PM

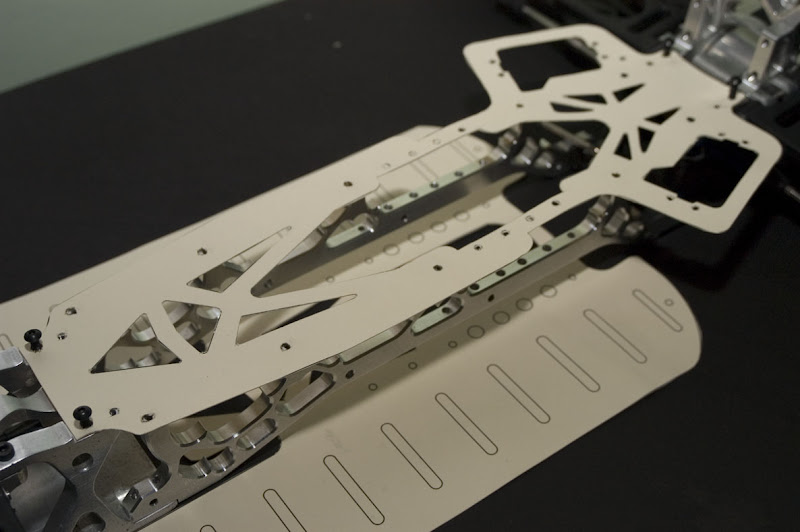

Thanks for all the help guys... Here's a little preview of what I am working on.

Alien |

|

|

|

|

|

(#10)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,061

Join Date: Oct 2007

Location: Thousand Oaks CA

|

05.02.2009, 06:05 PM

That is a very pretty maxx.

|

|

|

|

(#11)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

05.02.2009, 07:47 PM

Very nice deisgn indeed- FLM meets GorillaMaxx. Have you seen Serum's customized FLM chassis, has a similar bottom plate design attached to the FLM braces.

|

|

|

|

|

|

(#12)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.03.2009, 02:35 AM

Thanks BL_RVO... I can't wait to see it in carbon.

Quote:

http://i228.photobucket.com/albums/e...ntruth/top.jpg http://www.unlimitedengineering.com/...6/DSC00532.JPG http://www.unlimitedengineering.com/...is2_375204.JPG Alien |

|

|

|

|

|

|

(#13)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.12.2009, 04:01 PM

Update time.. The laser ( http://www.engravingsolutions.com/ext.html ) did not work so well.

It started etching into the carbon, It started etching into the carbon, but at the same time the epxoy melted causing the fabric to be fray  (same thing Ryu James experienced). (same thing Ryu James experienced). So, for now, I'm going to be using 3/16 Lexan to build the chassis hoping it will hold up until I find another option for cutting the carbon here. Thanks for you help guys Alien |

|

|

|

|

|

(#14)

|

||

|

RC-Monster Dual Brushless

Offline

Posts: 5,139

Join Date: Sep 2006

|

05.12.2009, 07:08 PM

Quote:

|

|

|

|

|

(#15)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.12.2009, 07:48 PM

Quote:

The shop that made the test for me does have a CNC, but it's not easy convincing them to make the cut because of the dangers with the dust and the fact they don't have the appropriate cutting tool.  I explained to them it could work if the carbon is wet and there is a vacuum source pulling the dust away. Where Water Jets are concerned, they are none. I will find a way to cut the carbon soon... Just not by who or when.  Alien |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode