|

It's been 21 month since I cleaned up the G3R |

|

|

(#1)

|

|

|

A Horse's Ass

Offline

Posts: 1,065

Join Date: Oct 2007

Location: Spokane WA

|

It's been 21 month since I cleaned up the G3R -

09.20.2009, 07:43 AM

It has been some time since I had the G3R apart. I planned to do it this winter but lost a rear differential and well the screws just kept coming out of it until it was apart. My original plan was last winter, but Shawn’s (TDC57) post of what one is suppose to look like after a good cleaning was just to damn tough of an act to follow. So I put that off until the thread slipped away. It's obvious now it will never go away so I'll have to just face that. It looks like I never posted a build thread for my G3R here at RCM. So just for historical factors this is the build thread that I had at TRX forum.

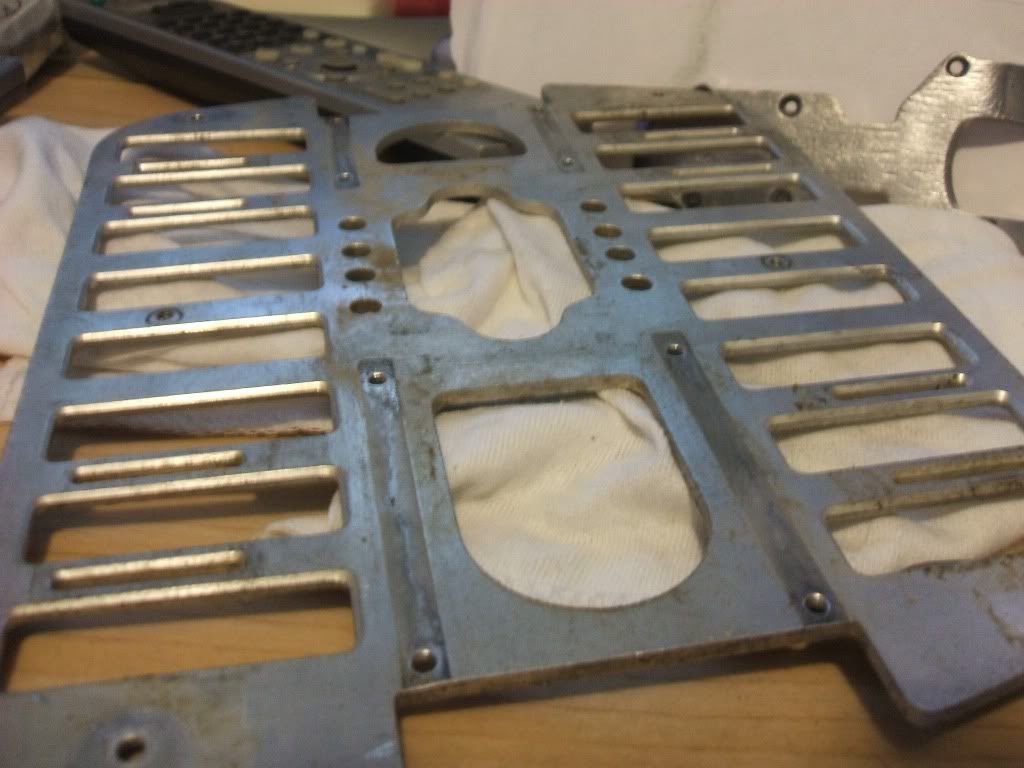

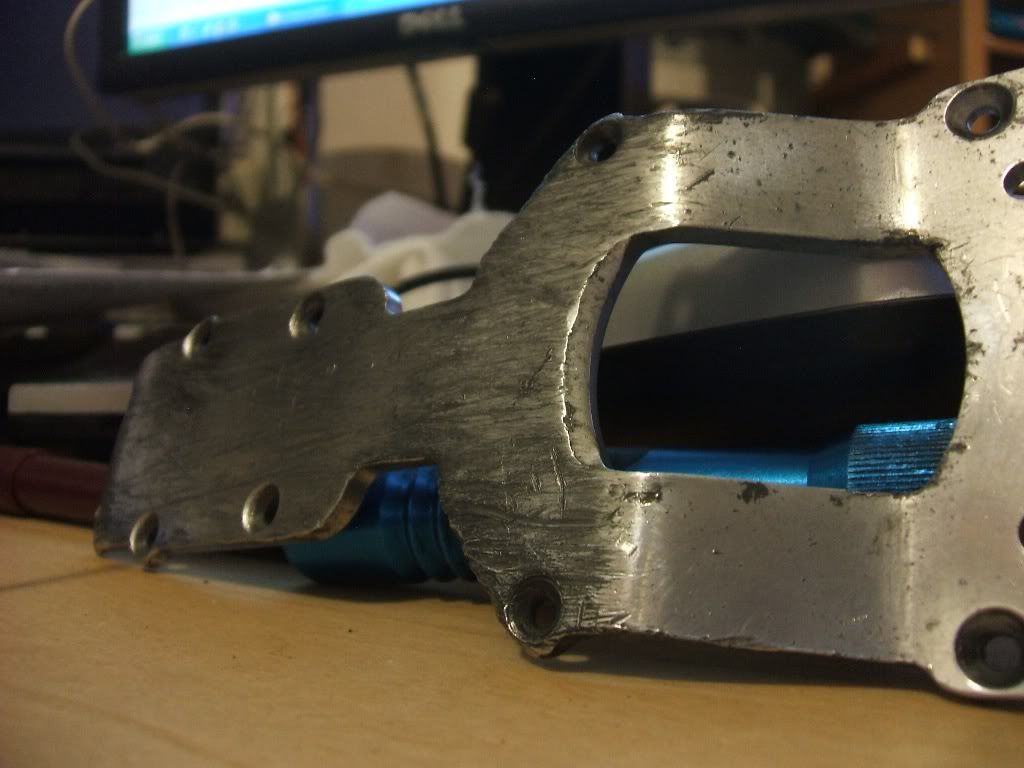

http://monster.traxxas.com/showthread.php?t=395978 It's not a long and drawn out one like Marks (mkrusedc) "My Neu Maxx is almost done" is.  Just kidding you Mark. Although ironically Marks post was the one that got mine to be 2 page long over there and still is only 2 pages. Thanks again Mark. A goal I thought it might never reach. Anyways pics of what the G3R looks like after such neglect. At one time I made some lexan protectors for the g3r skid plates. These eventually broke and never got replaced. I thought back then no big deal. If the two plates get chewed up too bad I will just order up some replacements. Well as the old say goes you only have one set of teeth so take care of them. If I knew I had only one set of skid plates. I may have lived the last 21 month differently. The G3R chassis where the batteries strap onto has a little bit of a bend to it on one side but nothing bad. Got it bent back close to original Just kidding you Mark. Although ironically Marks post was the one that got mine to be 2 page long over there and still is only 2 pages. Thanks again Mark. A goal I thought it might never reach. Anyways pics of what the G3R looks like after such neglect. At one time I made some lexan protectors for the g3r skid plates. These eventually broke and never got replaced. I thought back then no big deal. If the two plates get chewed up too bad I will just order up some replacements. Well as the old say goes you only have one set of teeth so take care of them. If I knew I had only one set of skid plates. I may have lived the last 21 month differently. The G3R chassis where the batteries strap onto has a little bit of a bend to it on one side but nothing bad. Got it bent back close to originalI got some cleaning and polishing tips from Shaun before his sudden departure from us. So I tried some wine and started working on it between 1:00 am and 4:00 am. I think he was pulling my leg. lol If anyone has any tips for the restoration of aluminum product please share. In the meantime I will be substituting his taste for wine with something that I prefer. I started on the front plate and took some off the top to try and smooth out some of the gouges. Looks a little better but is going to take some more work. blah, blah, blah,.....on to the pics.....

|

|

|

|

|

|

(#2)

|

|

|

A Horse's Ass

Offline

Posts: 1,065

Join Date: Oct 2007

Location: Spokane WA

|

09.20.2009, 07:43 AM

|

|

|

|

|

|

(#3)

|

|

|

A Horse's Ass

Offline

Posts: 1,065

Join Date: Oct 2007

Location: Spokane WA

|

09.22.2009, 05:33 AM

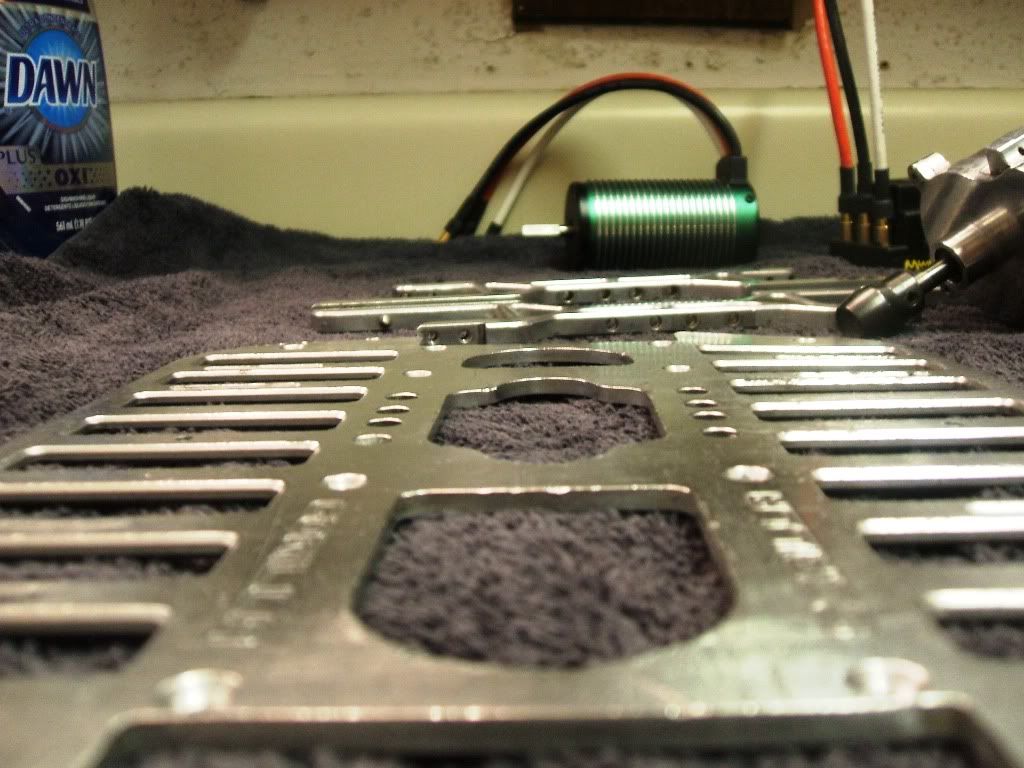

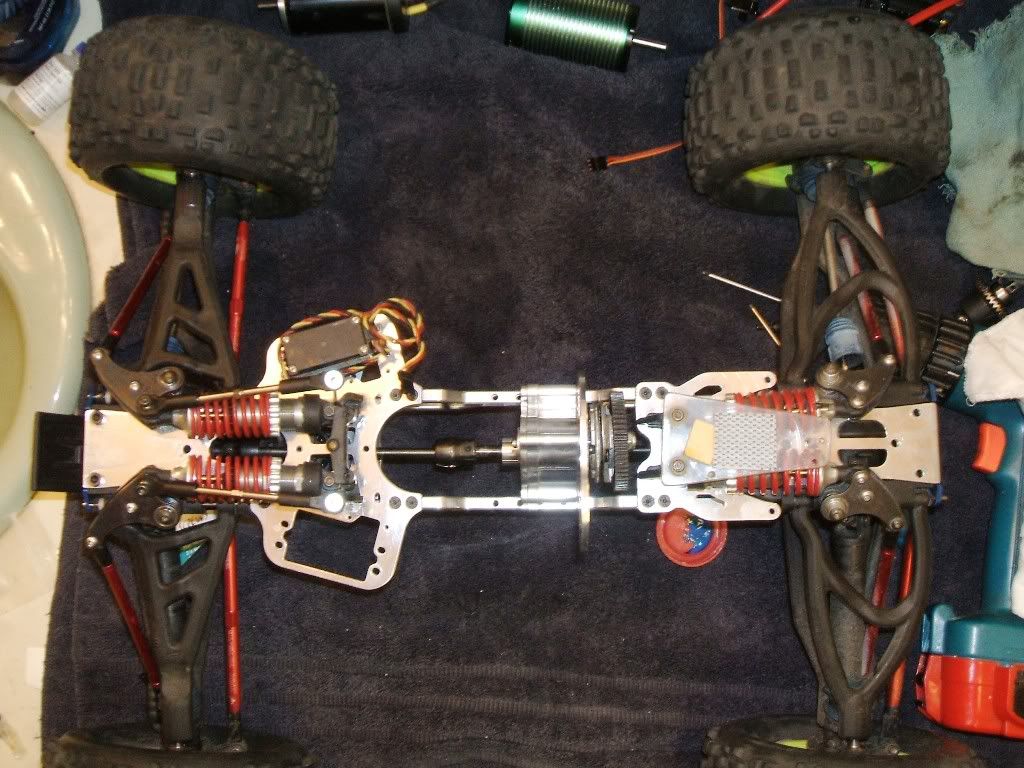

Well I wasn't very far into this cleaning project (no more then 10 minutes) when I started kicking myself for starting it with no snow on the ground. It made it to my long list of projects I started that I wished I hadn't. I let it become a rush job since I really wasn't into doing it after all and I had just got my first Mamba Monster in the mail and it was sitting there waiting to be tried out. Yes, I waited all this time before before I slept with the monster. In some cultures that is still respectable. Anyways the visions of blinding light off of the aluminum and pure mind numbing shine fell a bit short. It was due for a good cleaning and it is a lot faster now. That could be the 6s monstor though.

I got it cleaned and back together before it got dark out that day so I got to test out the monstor. Need stronger diffs now. Speaking of, the diff was how this got started but somehow I got the wrong pinion install. The one I put in was a little longer. It was really hard to tell. It made the rear drive line bind up. I had to take it apart three additional times until I noticed the pinion was sticking farther into the rear cup then another I had. It would bind up so bad my first thought was I installed the diffs backwards. The second time I thought maybe I shimmed the pinon too tight, and third time I was wonder just what the f was going on. Time wasn't on my side and nightime was approaching fast. Don't know how the bathroom counter become the spot to clean this up, but I was getting tired of being in there and not sitting down for such great lengths. When I tell people I spent most of my Satuarday in the bathroom, everyone assumed I was sick. Hmmm, calling in sick to work might be in the near future. Use it or loose it........   I had to take a lot off of the front skid plate to get most of the scratches out. Some are too deep. Would end up with a 1mm skid plate if I kept going.         I was impressed before with the work Shaun did on cleaning his. I have much more respect and appreciation for what an the excellent job he did now. I might have let mine go too long before cleaning or just didn't avoid the rocks well enough. There no taking away the time and dedication he put towards his spit and polish job. So in my book Shaun (where ever you are) you are still the man. I thought it before, I know it now. Thanks for the tips you gave me. Here's a toast to you bud. I miss the late night west coast toasts we use to share. Hope all is well with you and yours. Using the cameras flash gave it a bit more of the glaring reflection I was hoping for. |

|

|

|

|

|

(#5)

|

|

|

Guest

Posts: n/a

|

09.22.2009, 07:59 AM

Nice job cleaning up your chassis there mate. How hot does it get running that gearing?

I am still using the stock E-Maxx slipper on mine with 66/22 gearing. I was just wondering if the smaller spur is ok with the 2200kv motor on 4s? What was involved in converting to the Revo slipper? Are you running stock Revo diffs? |

|

|

|

|

|

(#6)

|

|

|

A Horse's Ass

Offline

Posts: 1,065

Join Date: Oct 2007

Location: Spokane WA

|

10.02.2009, 03:27 PM

Thanks.

I didn't have any problems running the gearing I did. Disclamer* It was rarely ever ran through grass, mostly gravel/dirt road bashing. I ran a fan and extra cap on the MM and the Neu 1515 1y didn't get ever get hot. Even after the hidden fan crapped out.  The smaller spur does limit the size of pinion though. I will be switching to one of the larger mod .08 spurs now. They have them up to 68 and I have s 72t now that uses the revo slipper setup. Depending on which tranny you have (E-Maxx, Gorilla Max G1, or the Gee1 Version http://www.rc-monster.com/forum/show...t=revo+slipper tranny) there are a couple different ways to use the revo slipper with the emaxx. Here's one of them. http://www.rc-monster.com/forum/showthread.php?t=6232 This is another way to use the whole shaft. http://monster.traxxas.com/showthrea...t=revo+slipper There should be a couple other option out there people have come up with. Using the revo slipper is an upgrade worth doing. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode