|

Custom Made Motor Plate |

|

|

(#1)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 323

Join Date: Feb 2008

Location: Durham, N.C.

|

Custom Made Motor Plate -

12.02.2009, 11:30 PM

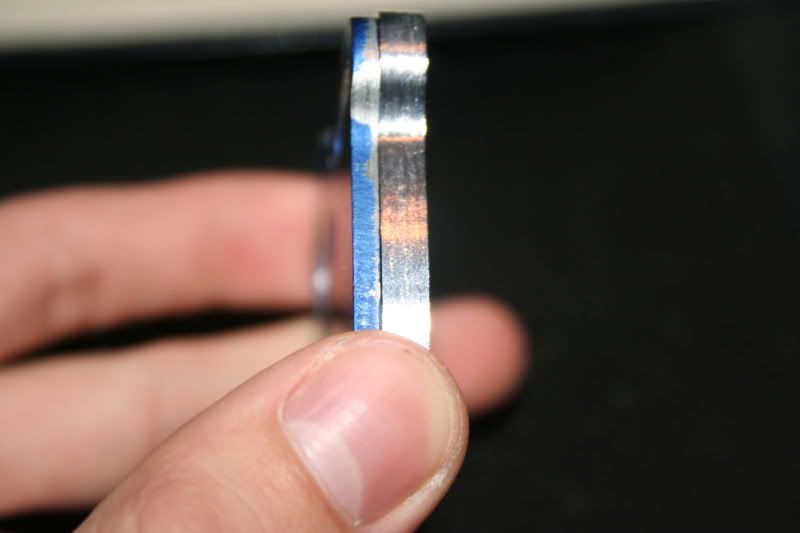

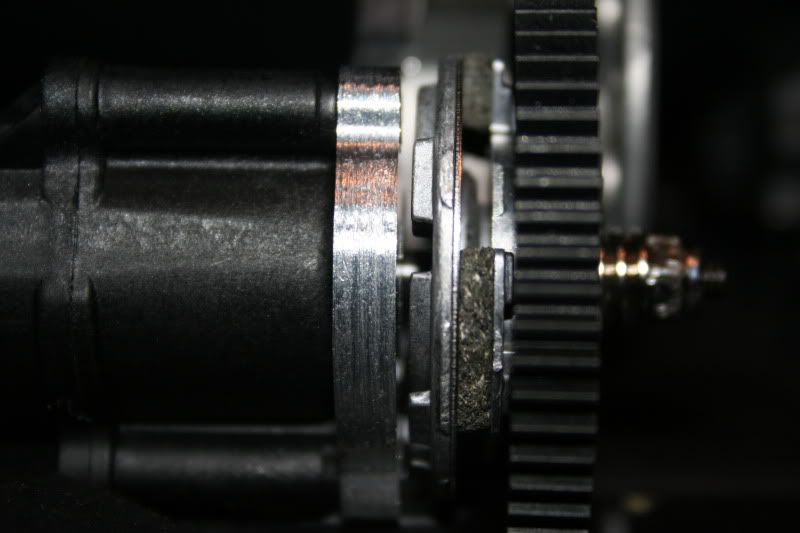

Knowing how the stock plate flexes, I decided to make my own. I made one out of 4.75mm 7075 aluminum. A bit BEEFY I would say lol.

All work was done with a Dremel and tungsten carbide bits. A big thanks to MisterCrash as he answered all of my machining questions as I originally had no idea what I was doing! All work was done with a Dremel and tungsten carbide bits. A big thanks to MisterCrash as he answered all of my machining questions as I originally had no idea what I was doing!  Beefy, eh?     Almost rubs. ;) |

|

|

|

|

|

(#2)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

12.02.2009, 11:42 PM

That's nice work man... did you do it free hand... or did you bolt the dremel to a bench?

|

|

|

|

|

|

(#3)

|

|

|

Guelph, Canada, eh!

Offline

Posts: 1,083

Join Date: Sep 2007

Location: Guelph, Ontario, Canada

|

12.02.2009, 11:55 PM

You have beautiful hands

You did really well, the plate looks awsome. You did really well, the plate looks awsome.

|

|

|

|

|

|

(#4)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

12.02.2009, 11:59 PM

Hand porn alert!

Just curious, but why didn't you just JBWeld two stock plates together? Nice job regardless! |

|

|

|

(#5)

|

||||

|

RC-Monster Carbon Fiber

Offline

Posts: 323

Join Date: Feb 2008

Location: Durham, N.C.

|

12.03.2009, 12:06 AM

Quote:

JK! I used the Dremel router attachment. Not the best router in the world, but you can't beat it for $30.  Quote:

Thanks. I couldn't of done it without you. :) Quote:

Because mistercrash tried it once. He still ended up bending them both. I don't think I'll have that problem now. :) |

|||

|

|

|

|

|

(#6)

|

|

|

Guelph, Canada, eh!

Offline

Posts: 1,083

Join Date: Sep 2007

Location: Guelph, Ontario, Canada

|

12.03.2009, 12:07 AM

The stock plates are made of very cheap aluminum, nothing like T6 7075 aluminum. Even when you double them up, they flex and bend out of shape.

|

|

|

|

|

|

(#7)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

12.03.2009, 12:12 AM

Cool... I was just looking at one of those on ebay... I'm going to need one soon... thanks for sharing rusty.

|

|

|

|

|

|

(#8)

|

|

|

2 KiloWatt RACER

Offline

Posts: 2,496

Join Date: May 2007

Location: Houston

|

12.03.2009, 01:42 AM

Nice work and Nice hands.

GTP-Pletty Big Maxximum+RX8. GTP-C50-6L Hacker+RX8. CRT.5-Pro4+ZTW esc. 24s2p EVG SX 49.6mph Ebike. 18s4p Raptor 60mph Ebike. 11.5KW |

|

|

|

|

|

(#9)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,402

Join Date: Aug 2008

Location: Twin Citys Mn

|

12.03.2009, 02:55 AM

great work

let me know if you want to make one for sale |

|

|

|

|

|

(#10)

|

|

|

RC-Monster Aluminum

Offline

Posts: 702

Join Date: Feb 2005

Location: n.c.

|

12.03.2009, 08:56 AM

nice work! I might be interested also.

Slash 4x4 163mph drc rail 150 mph phildogg6@yahoo.com https://www.youtube.com/channel/UC1g...MR6SqQkehkevwA my youtube channel |

|

|

|

(#11)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 323

Join Date: Feb 2008

Location: Durham, N.C.

|

12.03.2009, 10:06 AM

Lol, you guys are funny about the hands.

I will make a few, but only a few. I have enough metal left over to make 3-4 more. I'm only making them because I have no other use for the extra material. There is no use it letting a $20 6" square piece of metal sit in a box.  I like shaping metal, but it does take a lot of time to make one. I'll only make one at a time so I'll just contact somebody else when I'm ready to make another.

|

|

|

|

|

|

(#12)

|

||

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

12.03.2009, 10:57 AM

Quote:

|

|

|

|

|

(#13)

|

||

|

RC-Monster Brushless

Offline

Posts: 3,156

Join Date: Jul 2005

Location: Gramercy, LA

|

12.03.2009, 11:25 AM

Quote:

I'm sure the Traxxas plates are made in mass production on a huge automated stamp machine. I'm quite sure the machine could handle a little thicker material.... Is the cost of the material the only restriction? |

|

|

|

|

(#14)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

12.03.2009, 02:34 PM

Anything to save a buck, thats Traxxas's motto I believe..

Nice job on the mount dude, might have to look at the dremel router jobby myself- if you give your mount a rubdown with some fine grit sandpaper & 3in1 oil it'll look a million $

|

|

|

|

|

|

(#15)

|

|

|

Soldermaster Extraordinaire

Offline

Posts: 4,529

Join Date: Apr 2007

Location: Plymouth, MA, USA

|

12.03.2009, 02:56 PM

Very nice work!

How many bits did it take you to make that?

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode