|

Project: Flux XL |

|

|

(#1)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

Project: Flux XL -

05.08.2010, 07:40 PM

This project is already a few months along so it might take me a bit to catch up. I'll be posting some pics but most will be on photobucket.

The main focus of this project is to build a simplified Flux basher by removing legacy parts (gearbox, radiobox) and to use a single large battery with the TVPs. I was happy with the length of the Flux, the XL chassis is just a necessity for having a battery within the TVPs. Initially i looked at conversion kits but all of the XL ones had limitations that i did not want. Like small battery compartments and they all still used the gearbox. So i started investigating if it would be possible to have a decent sized battery compartment within a custom XL TVP layout. Initially i was inspired by Janezki's Savage XL-E build and various center diff builds. Whatever i looked at it either had a small battery compartment, batteries still in boxes, batteries or motor mounted high. After testing layouts with a cardboard prototype i discovered the limiting factor was the steering assembly. It limited a front mounted motor from being moved forward and\or forced it to be mounted rather high. So the real crux of this build is that i have reversed the servo saver arm to move the steering linkage away from the center of the chassis. I tried various other solutions but this was the only one that looked like it might work. Initial cardboard protoype  This the first project thread i've ever done so please feel free ask questions, make suggestions or critique etc

|

|

|

|

|

|

(#2)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

05.08.2010, 08:15 PM

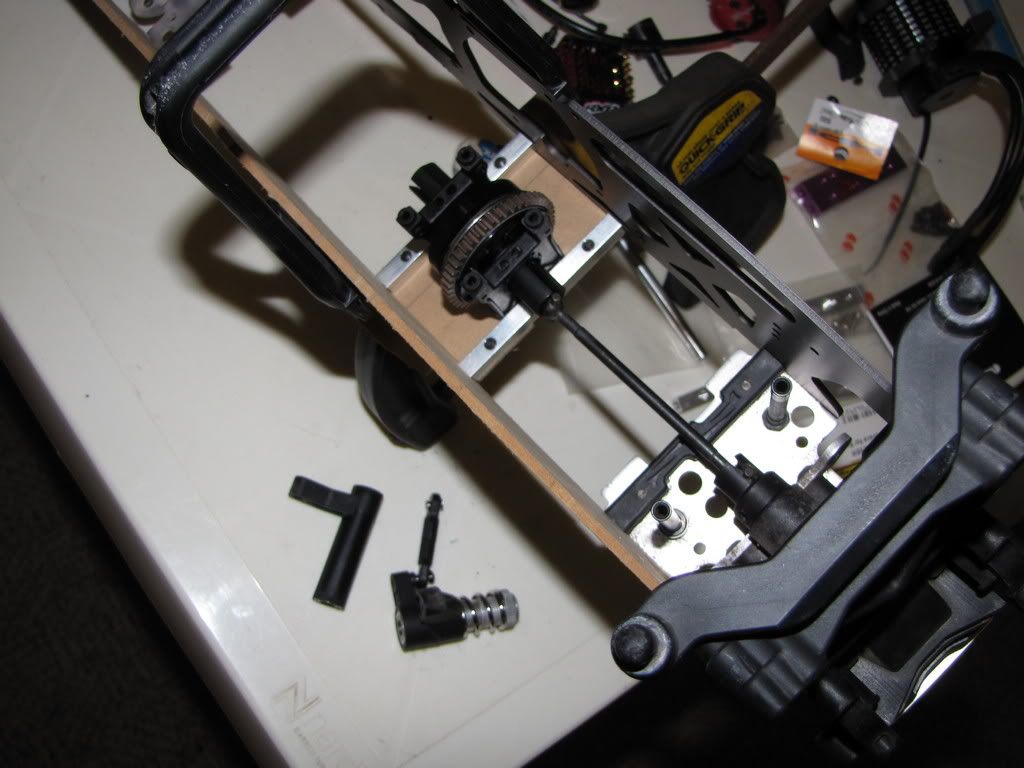

Early layout testing. I bought some 3mm MDF to use for further prototyping and thats what is bolted up in the pic. The final layout will be very similar to this. The steering servo will be mounted upside down as i wanted to incorporate the RPM Savage X skidplate mod and the bottom mounted servo would not fit with the skidplate cross brace. The receiver box will also likely be moved to the outside of the TVPs. I planned to use a center diff (under where the receiver box is in the pic) but this later changed when i discovered the slipperential

. Also decided on using a Tekin RX8\T8 system after probs with my MMM. . Also decided on using a Tekin RX8\T8 system after probs with my MMM. More to come when i have time. |

|

|

|

|

|

(#3)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

05.10.2010, 05:55 AM

After I discovered the slipperential and found out what it was i decided to try it over a straight up center diff. Spur is 46 tooth to keep it mounted low. I plan to use a 14t pinion with a 1550kv motor.

Assembly. Used 100K diff fluid as this will be basher.  Had a few probs during assembly. 1) Slipper pads didn't fit and they required a fair bit of filing 2) Burs around the outside of the thrust washers ..more filing 3) Was very difficult to get the pin in the spur gear side diff cup, there just wasn't adequate room. It's also leaking on the non-spur side so i will have to take that side off and try to fix. Slipperential mounted on test MDF\crossbrace bracket in place in the chassis. Diff mounts are Vorza\Hot Bodies. I'd really like custom single piece aluminium mounts that hold a bearing and bolt directly to the TVPs ..maybe later.

|

|

|

|

|

|

(#4)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

05.11.2010, 08:59 AM

The battery tray from the Vorza looked like a good way to keep the battery secure in the TVPs. Took me some time to track one down but unfortunately once i got it i found it was unsuitable. The expanded areas on one end for the battery wires meant it wouldn't quite fit between the TVPs. The way it mounts also raised the battery up more than i had hoped (see second pic). The holder mounting holes are also not properly asymmetric in that if you wanted to rotate the holder 180 degrees to have the battery wires at the other end you couldn't use the same holes in the mounting surface.

Eventually i found these Tekno battery trays. They are simple, light and should do the job. They take batteries up to 51mm wide and the longer one can handle batteries up to 165mm long. The long one fits in the new XL layout nps

|

|

|

|

|

|

(#5)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

05.11.2010, 07:51 PM

Looks promising

Sorry you had issues with the slipperential, sounds like some parts just werent deburred or whatever after manufacture- rare for an RCM product I can assure you, but stick with it, the end result will be more than worth the hassle at this stage

|

|

|

|

|

|

(#6)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

05.13.2010, 07:33 AM

I've considered quite a few motor mounts for the project. The motor will be mounted directly to one of the TVPs.

Stock Flux clamps - Will work but the bolt side has to go up to avoid the center shaft and one of them must be modified to fit the 42mm front of the Tekin motor. Vorza motor mount - No go. No way to modify it to fit a Tekin motor. It's just to thin and the mounting points are wider apart then i thought and not symmetrical. You can also only mount a motor one way around in this mount.  Tekno motor mount - There is one made specifically for 42mm motor. I'm not a fan of front secured mounts but at least it has the cage to back it up. It will require a little grinding on the corners due to the angle it makes to the center diff drive cup.  What would be great is this mount but made for 40/42mm. Basically a stock flux clamp but without the unecessary bolt bit jutting out one side. I've sent a mail to Mike asking if he can make them. Didn't get a reply to the previous mail i sent asking about modifying a stock mount so i'm not holding my breath.

|

|

|

|

|

|

(#7)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

05.13.2010, 07:50 AM

neil: I will definitely stick with the slipperential and give it a good go. It's a very unique and interesting piece, engineering and capability wise.

I going to try and complete my MDF mockup this weekend. If i get that far i'll post some more pics. I have some quotes for the 3mm aluminium sheet i need. Quite cheap, though so far i can only find 5083 'marine grade' aluminium alloy which is apparently similar strength to 6061 but maybe not as stiff. I might give it a go and try cutting it myself since it's cheap and it won't matter too much if i mess up. Out of interest, here are the weights of some parts that will no longer be used:- Stock gearbox with spur - 366gm Stock battery boxes with foam, mounting blocks - 133gm each Stock radio box - 141gm Total - 773gm ...that's a fair bit considering the replacement parts won't weigh much |

|

|

|

|

|

(#8)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

05.13.2010, 09:30 AM

Interesting design, but by the looks of it you will have the battery mounted in the rear?

I would suggest that you mount the battery up front, as having the battery weight there will help counteract the gyroscopic force of the heavy tires when you are in the air and on throttle. If you have the weight biased backwards you will always jump way nose high and have to use the brakes to land properly. I am working on a stretched chassis setup for savage at the moment. I kept the tranny and flux style motor mount/location. Added the extra length in the front and will have the battery tray act as a servo mount as well. Still need to cut the second tvp and make the battery tray. Bandsaw broke so I have to scare up some parts! |

|

|

|

|

|

(#9)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

05.13.2010, 07:55 PM

They actually have some larger motor mounts on that German site, but they are slightly different:

http://shop.in-racing.de/index.php?p...gc06mlcpng975a ( scroll down ) I'd guess you've seen them though. Mike is always busy in the shop, dont take it too personally if he doesnt respond to emails quickly ( or at all )- got to get the new baja conversion kit done & some revo hybrid diffs etc. And Linc, yeah, you really need to finish that chassis of yours...

|

|

|

|

|

|

(#10)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

05.14.2010, 12:03 PM

motor mounts are tough to find... I decided to just utilise my stock ones and modify them to fit... I feel my more secure using it rather than anything else... Just piece of mind when the truck is flying through the air and taking large jumps

|

|

|

|

|

|

(#11)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

05.17.2010, 04:48 AM

linc: Yes, rear mounted battery. I contemplated forward mounted but i wanted to try a layout with everything as low in the chassis as i could. I assume your layout would have the battery mounted above the steering\servo? With the reversed servo saver in my layout it would be possible to fit a battery down the side of the servo though...

The weight bias is shaping up to be very central, see my next post neil: Yeh i'm a bit tentative about those hose\worm screw style clamps. They might be strong but it would take some convincing to get me to try them I have no issue if Mike replies to me or not. I'll just make do with what i can get hold of. Jahay: Know what you mean. A motor is a fair whack of mass to have cartwheeling at 60 km\hr in your truck. The Tekno mount seem solid enough and it fits once modded so i'm gonna give it a go. I'm going to add two extra motor faceplate holes though so i can secure it with 4 bolts |

|

|

|

|

|

(#12)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

05.17.2010, 04:51 AM

_db when it was time for me to find a motor mount, i was just so unconvinced that those jubilee style clamp motor mounts were ever going to be able to handle the torque brushless motors release!

|

|

|

|

|

|

(#13)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

05.17.2010, 05:26 AM

Didn't quite get to a full mockup on the weekend but i think this is a far as I need to take it. Note the balance point is just a touch forward of central. The distance between diff drive cups is about 40cm. I don't think the balance point will change much with the full build. The battery i bought has helped with this a bit. I ordered a ZIPPY Flightmax 5800mAh 5S1P 30C 145x50x49mm, 776g. Fortunately for me the actual stats when it arrived were 145x49x44mm, 727g. You can see how much space i have for larger batteries but this battery pushed forward will help keep a good balance point. The battery can be mounted 'sideways' (as shown) to lower CoG. The battery tray is also mounted a bit high ..it could be lowered another 4mm or so. I went with an EC5 connector for the battery. Sure made soldering the 8 gauge battery wire easy. Anyone else use these? ESC was going to be mounted above the servo but the servo has to come up a bit as the servo horn bolt will just touch the casing on full lock with how it's mounted now. So it will be in the position in the pic. There are two joint posts between the roll bar atm. I'll probably devise a custom bracket instead to mount the ESC to. The receiver will either just be double sided inside the TVPs or stuck in a small Team Associated box and mounted on the outside of the TVP. The modified Tekno mounted fits well. There is about 1.5mm between where i ground the corner of off it and the slipperential diff cup but the mesh is too tight atm so it will likely be about 2mm. Thats with the 14t pinion which will be as small as i go. Even though the mock chassis is MDF it's very stiff now that i have battery tray bolted in. It's mounted on stock motor deck mounts. I'm thinking i will add another two cross members to bolt the RPM Savage X skidplate to instead of the 'slot in' plastic crossmembers. So the final build should be plenty strong. Well at least i hope so, I have only be able to get hold of 5083 aluminium alloy. linc, what grade is the aluminium for your stretch build? I used drinking straws to test the center driveshaft lengths. Looks like i will need about a 96mm and 161mm shafts. Haven't looked for those yet but if anyone has an idea lemme know. The slipperential diff cups are rather long so i might get away with shorter shafts if i pack them with o-rings. Lastly, you might be wondering about the rod end attached to the shock tower. I've been trying to think of a way to support the shock tower as it bends a lot and eventually becomes permanently deformed. I'm thinking two tie rods one on the end of the shock bolt and the other bolted to a hole in the TVP. Not sure if this will be too stiff though, the tie rods will have some give but i am still considering it. Lots more pics on photobucket |

|

|

|

|

|

(#14)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

05.17.2010, 05:52 AM

looking gd!!! coming together... it is huge!!! Removing that tranny and putting in a centre diff must save weight and increases useable space in the chassis!!!

|

|

|

|

|

|

(#15)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

05.18.2010, 04:13 AM

Picked up my Al alloy plate today. 5083 H321 grade. Has similar mechanical properties to 6061 from what i have read so it should do the job ok. $29 AU for 40x60cm 3mm.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode