|

My brushless HPI Nitro MT Project |

|

|

(#1)

|

|

|

RC-Monster Carbon Fiber

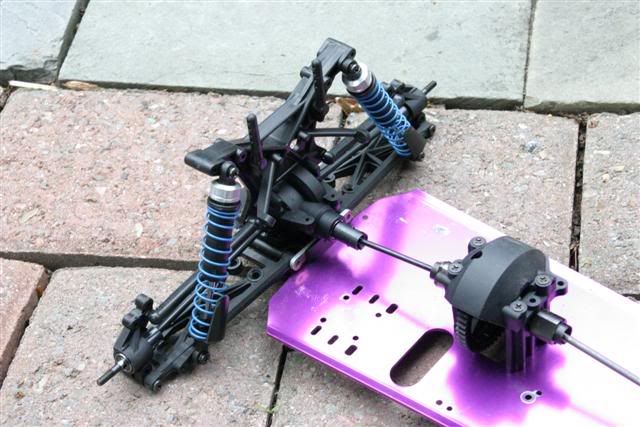

Offline

Posts: 139

Join Date: Oct 2005

Location: NJ

|

Well my first real brushless project has begun with me winning a used HPI MT roller with radio for $60. :eek: My only BL experience is with an RC10T2 with a Novak SS5800. I liked the power but needed more and needed it to be 4WD. I was thinking a 1/8 buggy, but figured a 1/10 would be cheaper and easier. I saw Camel's MT18SS and liked it, but didn't want to spend that much, so I picked up this MT.

I'm thinking a Feigao 380c 6L or 8S (8T here at RCM?) with a Warrior 9920 and 8 cells. My max is 8 cells due to my charger limit, and I'd rather not split it into 2 packs as this makes charging very long. Which is the better choice, the 6L or 8S? What size pinion should I look at? Any other recommendations for a controller? This will be strictly for bashing. I'll update this as it progresses...wish me luck! :dft003: |

|

|

|

|

|

(#2)

|

|

|

RC-Monster Mod

Offline

Posts: 6,254

Join Date: May 2005

Location: Baton Rouge

|

05.22.2006, 08:10 PM

I would go for a 8S since it will have more torque and shouldnt heat up as much.

|

|

|

|

(#3)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 139

Join Date: Oct 2005

Location: NJ

|

05.22.2006, 08:31 PM

I thought the L series would have more torque?

*edit* Or do you mean that a 6 turn L will have less torque than an 8 turn S? I can't find any numbers from Feigao for torque. |

|

|

|

|

|

(#4)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

05.22.2006, 08:52 PM

The 8s won't necessarily have more torque, since it has to do with the number of amps the motors will pull. Unfortunately, Feigao doesn't publish the kt ratings (torque constants) for their motors, so we can't tell which motor will put out the most torque at the same number of amps.

It's relatively tough to decide without actual numbers which motor has the highest kt. The 380C 6L is longer, but the 540 8s is larger in diameter. They have similar kv ratings (by several hundred). If it were my decision, I would pick the 380C 6L. The can of this motor is a heatsink, so it can dissiapate heat well, and it has removable endbells that won't pop off like the 8s's endbells will. This also makes motor maintenance (bearing maintenance) easier. Besides those things, the 380C 6L is less expensive. |

|

|

|

|

|

(#5)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 139

Join Date: Oct 2005

Location: NJ

|

05.22.2006, 09:09 PM

Thanks for the reply. I actually meant the 380c 8S, not the 540. The 6L pulls 69 amps and the 8S 52 if that helps.

|

|

|

|

|

|

(#6)

|

|

|

RC-Monster Mod

Offline

Posts: 6,254

Join Date: May 2005

Location: Baton Rouge

|

05.22.2006, 10:28 PM

Actually, they call them a 8T instead of a S. But yes, out of those 2 I would also choose the 6L.

Metalman, in theory, wouldn't the 540 8S have more torque than a 380C 6L? |

|

|

|

(#7)

|

|

|

"Out of spec" enthusiast

Offline

Posts: 820

Join Date: May 2005

|

05.22.2006, 11:47 PM

kt in oz/inch/amp is 1352/kv. Kt is always proportional to kv. So a higher kv motor will always have less kt. The total torque depends on the number of amps times the kt. In theory, a 540s will have slightly more torque than a 380c 6l. They both will draw about the same amount of amps, but the 8s having ~4400 kv verses the 6l having 4900 kv will have slightly more kt. Once you gear the 8s higher to compensate, both motors should theoretically have the same power output, although the 6l spools up faster in real life.

Sub 7lb, lowest CG of any 1/8 buggy http://www.rc-monster.com/forum/show...894#post367894 Area 52 Ranch Raceway T.R.C.R. |

|

|

|

|

|

(#8)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 139

Join Date: Oct 2005

Location: NJ

|

05.23.2006, 07:50 AM

Hmm, good info. I'll probably go with the 6L. Hell they're cheap enough now that I can just buy another one to play with if I want to.

|

|

|

|

|

|

(#9)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 139

Join Date: Oct 2005

Location: NJ

|

06.04.2006, 06:04 PM

Well I went with the 6L and Mtroniks Truck. Here's a few pics:

How I got it. It looked cleaner it person:    Cleaned up:    First attempt at a mount….lol  That’s better:  Not the sturdiest thing in the world but we’ll see how it holds up. I just bent a stock mount for a Tamiya MaxClimber.  And the modified radio/servo tray:

|

|

|

|

|

|

(#10)

|

|

|

"Out of spec" enthusiast

Offline

Posts: 820

Join Date: May 2005

|

06.04.2006, 08:57 PM

Nice! Let us know how it runs.

Sub 7lb, lowest CG of any 1/8 buggy http://www.rc-monster.com/forum/show...894#post367894 Area 52 Ranch Raceway T.R.C.R. |

|

|

|

|

|

(#11)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 484

Join Date: Dec 2005

|

06.05.2006, 09:36 AM

You may get a lot of flex from that motor mount, which will affect the gear mesh. The mount may need more than two screws holding it to the chassis. Check out this thread to see my motor mount. It's overkill really, but there sure isn't any flex.

http://www.rc-monster.com/forum/show...&highlight=mt2 |

|

|

|

|

|

(#12)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 139

Join Date: Oct 2005

Location: NJ

|

06.05.2006, 11:22 AM

Yeah I saw your MT2 thread. I know the mount isn't great, it's temporary until it causes a problem. I liked cold fusion's but I didn't like people sending money and not having a mount months later. I don't know anyone with a machine shop and e-machine wants $60-$80 and a month to make one so I'm kindof stuck at the moment.

|

|

|

|

|

|

(#13)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 484

Join Date: Dec 2005

|

06.05.2006, 01:30 PM

Yeah, I'm lucky that I've got access to a machine shop at work (plus a lipo charger). :)

|

|

|

|

|

|

(#14)

|

|

|

RC-Monster Mod

Offline

Posts: 6,254

Join Date: May 2005

Location: Baton Rouge

|

06.05.2006, 06:17 PM

I think adding a brace would make it strong enough. I would use something like a Hyper 7 rear chassis brace.

|

|

|

|

(#15)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 139

Join Date: Oct 2005

Location: NJ

|

06.05.2006, 06:59 PM

I was actually thinking about that or maybe something going to the spur gear housing. I don't do 20 ft backflips like a lot of people here that I've seen so it may just be ok, but I'll probably end up with a brace of some sort.

*edited* I DON'T do backflips lol HPI RS4 Nitro MT - Mamba Max 5700 - 2S 5500mah Lipo MRC Thunder King - Mtroniks Truck ESC + Feigao 9L - 3S 6000mah Lipo |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode