|

|

|

|

|

(#1)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

Quote:

Most people I've encountered love Zombies just never buy em. Really. Badlands normally get the job. Although they roll far to much for me as I have said. So I would have likely been happier with Zombies as far as badlands go. My next tire will be a truggy tire for performance when needed around truggs. Tell me about the $! Here's my wish list: UE steering the Proline is great but I need alittle more. 8mm stubs because I bent one of mine Maybe full front and rear racerX with set back high impact style for the 8mm cvds and added length and geometry and bling of course MAYBE 7075 t6 billet bulks so that I can use 7075 Knuckleheads 4 more super shocks Lite Racing shoes and wheels Couple more bodies 1 bashing 1 racing RCM cdmotor mount and maybe slipperential Maybe some lighter ball joints. A RX box for the hideous wires everywhere. Fan for MMM Maybe home-made custom made batt boxes Maybe some badlands straped up to some skinny wheels and taped. I've got a crazy idea, check it out: I might cut off the battery trays so that I could lose the weight and could strap the batts to the sides of the chassis rails like on a Flux with some protective batt boxes!!! Would make For some awesome C.O.G! Then if I wanted I could mount the batts up like one set is now behind the tranny over the monoblock inline for some hot bashin! Would be on my way to one ultimate one of a kind truck!  Whats the public opinion on that?!! |

|

|

|

|

|

|

(#2)

|

||

|

RC-Monster Square Tube

Offline

Posts: 1,367

Join Date: Jun 2008

Location: CNY

|

11.20.2009, 11:12 PM

Quote:

I wanted to see if I could do it without inverting the tire. I managed to and they run amazingly true and balance is no worse than it was, at least. I was able to get one full run around the center as the profile is flat enough that there isn't much wrinkling with the tape. As for the outer sections, in order to get it to lay flat I used 3-4" sections overlapped at least 1/4". You have to do a zigzag crosshatch type thing to get the tape where you want it. Major handling improvement, and didn't lose much at all on speed. I was expecting about a 5 mph drop, but apparently the weight on my Mute was keeping the diameter roughly the same on the contact patch, even while the rest of the tire was playing pufferfish. I locked a front wheel to get 2X speed with the diff and got no sign of ballooning, so theoretically they should be good for 60+. Not happening, but nice to know. Strangely after so long with minimal wear, they are showing wear after 3 or 4 runs with the tires taped  Not pretty, but very effective! My Videos: http://vimeo.com/user2236105/videos |

|

|

|

|

|

|

(#3)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

11.20.2009, 11:50 PM

Quote:

|

|

|

|

|

|

|

(#4)

|

|

|

RC-Monster Aluminum

Offline

Posts: 638

Join Date: Sep 2008

|

11.10.2009, 11:30 AM

I like the side saddle idea is there enough room height wise. What do you need about 160 mm with the box and all?. Have you seen the build wher the guy basically made a LCG flm chassis with carbon fiber. That thing was trick.

|

|

|

|

|

|

(#5)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

11.10.2009, 11:44 AM

Quote:

If the braces don't have the height I will just go above, you know let them stick up above the upper deck. I'm thinking of using something off THIS KD PAGE What do you guys think? Maybe the Flux saddle trays? |

|

|

|

|

|

|

(#6)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

11.10.2009, 12:07 PM

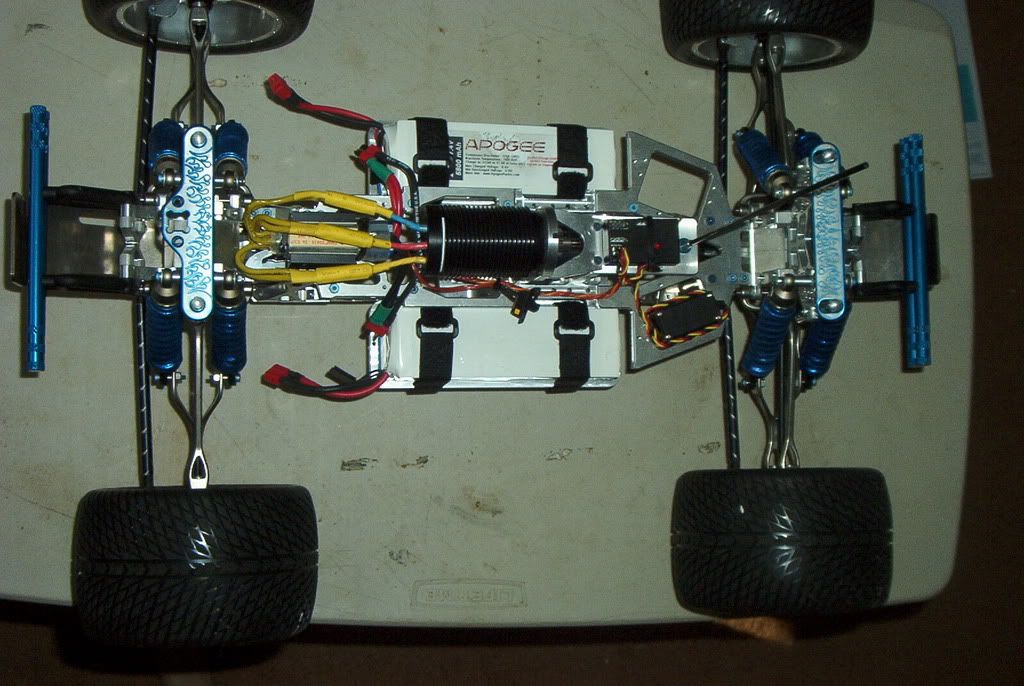

Hey Zack... You can use the below setup as reference for your mod... I know for fact lowering the FLM's CG will make a big difference.

The actual thread - RC-Monster Maxx - Part Deux Hope this helps... |

|

|

|

|

|

(#7)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

11.10.2009, 12:27 PM

WOW I can't stand it!! I will do this!!! Saddle style will be harder than I thought as there is alittle bit of the top plate that can not really be cut off. I think I will widen my center skid to kind of rest the batts on not necessarily use it as a tray though.

Serum Edition! Serum's LOW COG FLM |

|

|

|

|

|

(#8)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

11.10.2009, 12:43 PM

You can make a new gear box skid from a piece of 1/8 aluminum sheet, hang it off spacers and have 'wings' extended from it to facilitate bolting the battery trays on.

|

|

|

|

|

|

(#9)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

11.11.2009, 11:10 PM

BOMB-PROOF comes to mind! Thinking of doing the winged center skid in lexan...

|

|

|

|

|

|

(#10)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

11.12.2009, 01:28 AM

Aluminum!!!

... The finished product will so much better than lexan... ... The finished product will so much better than lexan...

|

|

|

|

|

|

(#11)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

11.12.2009, 08:57 AM

Aluminum is the most difficult for me to get. How do you cut aluminum? I've got lexan and I know people who can cut it for me. (i might can cut it myself) How do you cut it anyway? I could order a big 3mm thick sheet of carbon fiber from FullForce. But how would I cut that? Also how do you countersink the screw holes in all three materials? I see some of how you did the cf but I'd like to know in more detail.

|

|

|

|

|

|

(#12)

|

|

|

RC-Monster Aluminum

Offline

Posts: 638

Join Date: Sep 2008

|

11.12.2009, 11:00 AM

I have cut all three material with a hand held jig saw but a band saw would probably work best. lexan is pretty flimsy if you use that make sure you use at least 1/4". 3MM Carbon fiber would be best though IMO.

|

|

|

|

|

|

(#13)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

11.12.2009, 04:33 PM

Quote:

Can't you find some sort machine shop or garage that will have 'scraps' laying around, you won't need much for this mod. 1/8 - 5/16 thickness will work just fine. Where cutting is concerned, I'm currently using a few simple tools to make shapes out of aluminum. - A nice clamp/vice to hold the material - A hack saw... great for general shapes and lines (cuts through aluminum with no effort) - A Dremel with cutoff wheels, a tungsten carbide cutting bits is always nice and some sanding drums. I draw all my designs in Adobe Illustrator (you can do it by hand if you wish) and print them out... I'll lay a couple strips of masking tape on the aluminum sheet... Then glue the drawings to the taped side (this to allow for easy removal of the paper when I am done cutting the shape). After making my cuts with the hack saw, I'll use the cutoff wheels and sanding drums to fine tune the shape. Carbon fiber is easy enough when you use cutoff wheels.... Just be careful with this material, the dust is not the kind of stuff you want in your longs nor eyes... make sure you wear eye protection and a dust mask (damp)... Also make your cuts in a well ventilated area... Wetting the carbon before your cuts will reduce the amount dust flying around too. Use a sanding drum or sandpaper to clean up edges and lines. Countersinking both materials can be done with a countersink tool you can pick up at your local hardware. With carbon fiber I prefer you an abrasive cone shaped tool... In stead of cutting in the material, it grinds the surface away smoothly and reduces the chances of delamination... it's also a good idea to apply some thin CA (zap) on the area when you are done making the countersink (again reducing the chance of delamination)  A scroll saw would be so sweet for this too. |

|

|

|

|

|

|

(#14)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 132

Join Date: Jan 2008

Location: Quebec Canada

|

11.12.2009, 05:59 PM

Quote:

this is a 4s 5000mah with a lexan homemade box

|

|

|

|

|

|

|

(#15)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

11.17.2009, 05:01 PM

Yeah Quebec I've always liked your truck!

Although I don't see your lexan battery box I do see your homemade spoiler. Nice! ... Bad news:   Hopefully I can get this worked out before too long. Pictures from the mountains should be up 2night. Alien, great advice! It will certainly be my main point of reference! I can't thank you enough! All this is very exciting! Would any of these make a good tungsten carbide cutting bit? |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 2 (0 members and 2 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode