|

|

|

(#61)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

04.23.2009, 02:20 AM

Im wondering if all the little 4mm holes I drilled in my chassis at some of the more narrow points has weakened it. How easily do these chassi bend?

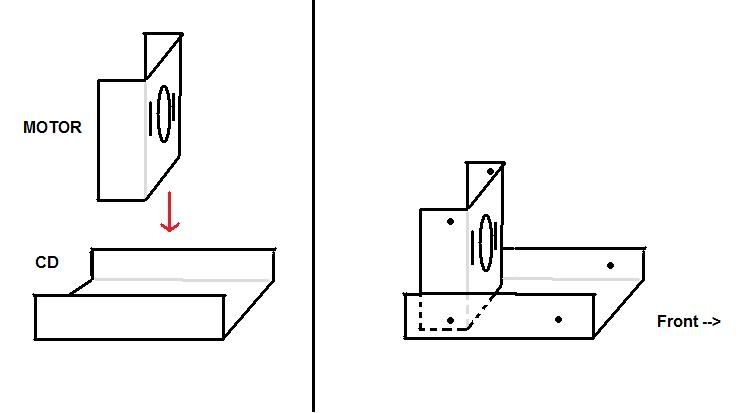

I decided to redo the center area as I just wasnt thrilled with some small mistakes I made. I ordered some 6061 aluminum and am going to re build my CD and motor mounts. Basically there will be two "C" shaped plates, one for the CD and one for the motor. The CD plate will allow me to mount the CD like it should be, screwed in from the bottom. The legs of the C will screw to the chassis. The motor C plate will have the legs attach to the inside of the TVPs and the body of the C will be facing the front so as to be close to the spur. Maybe hard to follow... have a look. I dont know why I didnt think of this in the first place, its so much simpler than what I did before and uses many less parts.

|

|

|

|

|

|

(#62)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

04.23.2009, 04:07 PM

Just found out that 6061 aluminum doesnt like to bend at all. So I wont be bending the alu to shape, just cutting the parts that were going to make the "legs" off and use some L shaped aluminum brackets. Getting more complicated again, but shouldnt be too bad.

|

|

|

|

|

|

(#63)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

05.02.2009, 02:48 PM

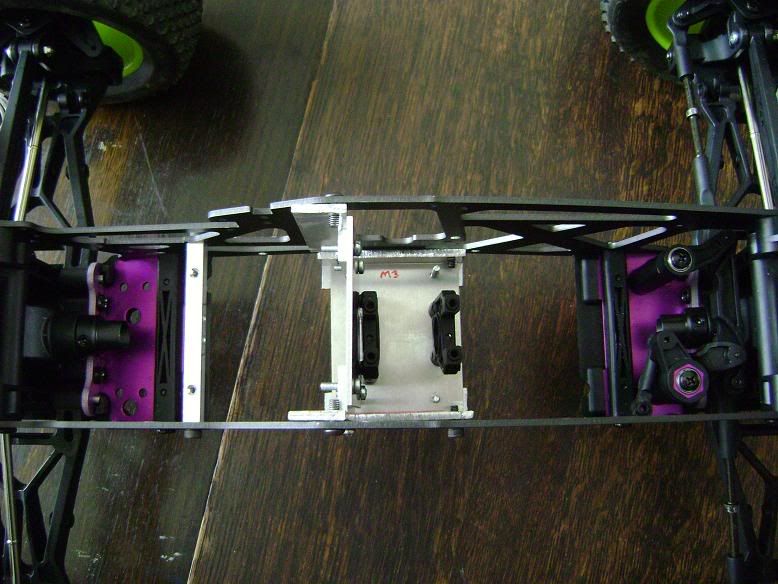

Alright Im about 75% done with the new mounting scheme. I had to use only tools I have here at my moms house since Im home from school now. So all I have to work with is an electric drill, a hacksaw, and some small clamps. No workbench, no metal files... UGH its hard and sloppy but I got the job done.

Its obviously not totally finished and its a rough draft mock-up right now but you'll get the idea. I think its going to work well, I just hope I used thick enough aluminum for the motor mount.

|

|

|

|

|

|

(#64)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

05.02.2009, 10:07 PM

|

|

|

|

|

|

(#65)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

05.04.2009, 04:49 PM

Heres a video so you can hear the noise my diffs are making. It stops for about 1 second if I push the input cup in towards the bulkhead. I can feel it move about a millimeter and when it rolls there is no noise until it moves back out after about a second. Anywhere here it is.

http://www.youtube.com/watch?v=YflTirLdhXQ Dangit, how do you embed video on here??? |

|

|

|

|

|

(#66)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

05.04.2009, 05:52 PM

sounds like the shimming is off... might need to make it a little tighter to et rid of the noise.

R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#67)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

05.07.2009, 10:32 PM

Well I took the rear diff out and put 2 shims between the pinion (? smaller gear of the 2) and the bearing it spins on to keep it pressed more against the big gear (bevel?). This seemed to kill about 50% of the noise, though it still makes a little. Its much better than before so Im happy and am just going to leave it as is. The front still needs it but Im in no mood to take the front apart to get to it right now haha.. (even though they are easy access diffs, my warhead tower mounting bracket is in the way and its a pain to get off...)

The shims I used werent the right size (too big diameter) but they arent big enough to make it a problem... hope not anyway! |

|

|

|

|

|

(#68)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

05.07.2009, 10:34 PM

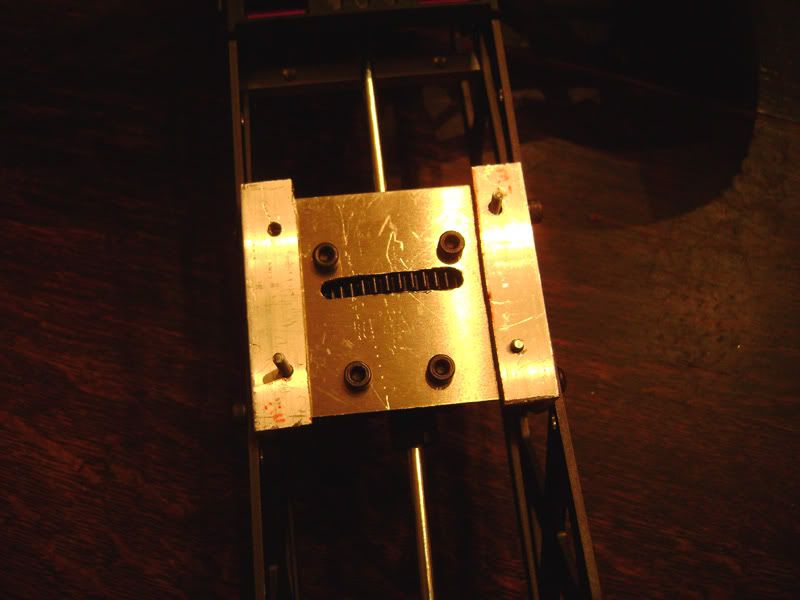

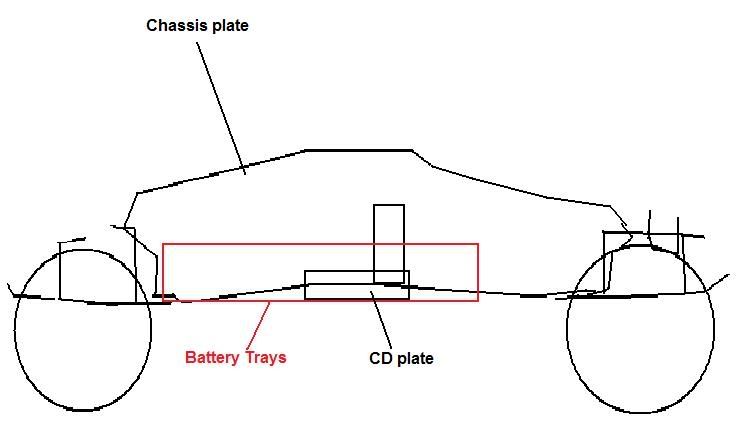

So I decided to mount the battery trays just barely below the CD plate, but just barely above the skid plates. So again if the truck bottoms out the battery trays will be fine, but if I curb the center part it will only hit the platic trays and not the CD plate, at least thats the idea. There will only be about 1 mm to spare on either side if this goes right. This is the only drawback to the way I decided to make this setup, but I dont plan on doing any rediculous bashing. Im going to be pretty careful with it, too big of an investment to trash around.

Heres an idea of what I was saying.  The extra bonus is that it gets the batteries REALLY low on the chassis. All the weight will be very low on this truck to Im hoping itll almost be a Savage Muggy when its all said and done haha...

|

|

|

|

|

|

(#69)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

05.07.2009, 10:35 PM

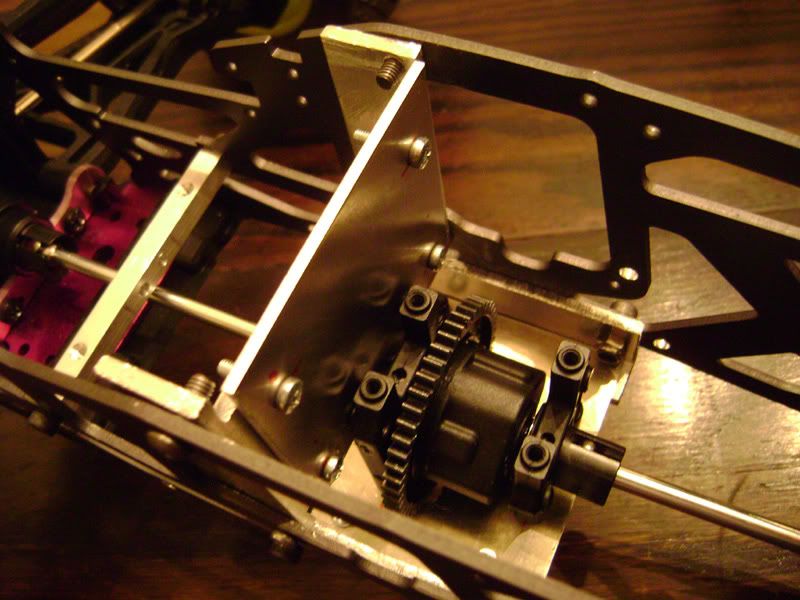

Got the motor plate pretty much done. If I need to drill out the hole a little more for the medusa it wont be a problem.

|

|

|

|

|

|

(#70)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

05.11.2009, 03:21 PM

More stuff came today, getting closer... running out of money fast..!! Good thing I found a part time summer job (still looking for full time...).

I also changed my mind (again) on the "battery tray as a skidplate" thing, it just wasnt a good idea, plus the trays are pretty flimsy. Im just going to order some thin aluminum and make a real skidplate. |

|

|

|

|

|

(#71)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 138

Join Date: May 2009

Location: Denmark

|

05.15.2009, 08:55 AM

Where does that center diff come from?

It looks like a damn easy way to make a brushless savage conversion... and it must save weight as well? Hmm... and on top of that you can center the motor. Nice :) |

|

|

|

|

|

(#72)

|

||

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

05.15.2009, 02:23 PM

Quote:

I wanted to be able to side mount the CD in the chassis so I could lower the motor and mount it on the side opposite the CD, but there wasnt enough room to have them side by side. On the savage-central forums in the project area, theres a guy who made a custom chassis and widened the area between the plates, and he made a CD mount for his nitro truck and has the nitro motor laying next to the CD, very cool idea. |

|

|

|

|

|

|

(#73)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

05.22.2009, 01:15 AM

Got the body all cut and drilled, its an HPI nitro GT-2 with spoiler. Now to decide on a color scheme... I dont want to do something typical, but Im having trouble finding something I like that will match the yellow wheels. These pics are without batteries or motor, so when finished the truck will sit a little lower. I wanted the body to sit as low as possible, and this is it with these towers.

I like what LarsenRacing has done with this body below, might give that a try. Still alot of options to choose from, just gotta pick the right one for me.

|

|

|

|

|

|

(#74)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 165

Join Date: Mar 2009

|

05.22.2009, 03:22 AM

That is one hot looking truck. I like the low stance. Kinda like a truggy now.

I really love the looks of it. |

|

|

|

|

|

(#75)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

05.22.2009, 07:40 AM

Wow I like it, that body looks great on your setup. now all you need is a wing mount :)

Have you decided what your exact setup will be? R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode