|

|

|

|

|

(#1)

|

|

|

RC-Monster Square Tube

Offline

Posts: 1,367

Join Date: Jun 2008

Location: CNY

|

03.05.2010, 08:11 PM

Not bad krawlin, with .023" wire MIG you could get some smaller beads, with just using a small circular motion. Lots of welders will only do that with stick welding, but it's almost always beneficial regardless the process you're using.

With a newer squarewave TIG it's possible to use a 2% Thoriated tungsten ground to a point with AC, which is what you need for some gorgeous aluminum beads. MIG is a great place to start, but once you've done some stainless with a TIG, nothing else compares. Looks pretty good, keep it up. My Videos: http://vimeo.com/user2236105/videos |

|

|

|

|

|

(#2)

|

|||

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

03.06.2010, 12:16 AM

Quote:

Quote:

And actually I am currently using .035'' wire in MIG, didn't think to change it out for thinner wire, but then again I have no idea what wire sizes they have in the welding shop here, probably thinner stuff but I didn't think to look. And I was taught to do the circular motion with MIG to get the nice bead and proper penetration, etc., but like I said before, when I tried it with these motor mounts, I ended up with a big fat glob, so I did a whole bunch of tack welds and very short welds in some places. Like Linc was saying though, probably lowering my settings would have helped, although to really end up with a good small bead I would have had to drop down to smaller wire like you were saying. Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

||

|

|

|

(#3)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,436

Join Date: Nov 2005

Location: Edmonds WA

|

03.06.2010, 12:47 AM

Geez.....Friday night, the wife is out of town, and here i am looking at pictures of your stinking welds.....

Christ I'm old.... Christ I'm old....How did the cuts look on your welds? (I assume they cut through the welds to check porosity and depth>) Is stick welding still taught? Horizontal overheads killed me - aced all the vertical welding - had a knack for the weave, I guess.

|

|

|

|

|

|

(#4)

|

||

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

03.06.2010, 01:22 AM

Quote:

And since this is a "first level" or "beginners/intry/starting out level" GMAW / MIG class, none of the welds I do in this class will be xray'd/tested, the teacher inspects them and signs off on them. The teacher has been welding for like 25 years or so, teaches MIG, TIG, and stick/arc welding, owns a welding business, and is certified for various welding things (not sure what certs. there are, I'm assuming for certain diameters of pipe and such), so he seems to really know his stuff about welding, can tell what it is I am doing wrong on any given weld, very helpful. But anyway, its usually in the upper level classes that they have some kind of independent lab group or VICA, something like that, cant remember exactly who/what, come to the college at the end of the semester, have you do a few welds, and gotta pay like $75, and then they xray the weld and cut it open with a shear I believe to look at it, and if everything looks good, it passes and then you get certified for whatever it is you welded (pipe, structural beam, etc.) And yes, they do still teach stick/arc welding. Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

|

|

|

|

(#5)

|

|

|

No Way....

Offline

Posts: 86

Join Date: Nov 2009

Location: France

|

03.07.2010, 02:22 PM

Hi

Nice conversion !!  it's funny cause I started to convert my MGT... starting of thinking about it !!  here's a pic of my differential support  I gonna use a MMM with a CC-Neu 1518/1Y motor The center diff is a X-Ray from a XB808 and here my MGT (a lot of upgrading...)  follow your post  (sorry for my English...I 'm French  ) )

|

|

|

|

|

|

(#6)

|

|

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

03.07.2010, 06:54 PM

Wow, that looks great! What brand of shock towers are those and where can I get them? Or did you make those yourself? Also, your design was the "final push" for me to update my design a bit, thanks for posting that! I'm looking forward to seeing how yours turns out.

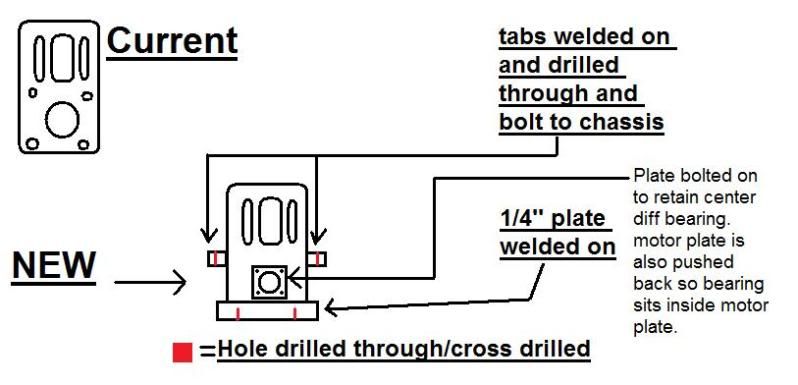

Since my motor plate bolts to a center diff mount, doesn't look as clean as it could, and probably not as strong as it could be either. So I decided to update my design, and used "The Dude"'s motor mount as inspiration for an update.....  Since 3/16'' is a bit on the thin side to drill for M3, I am going to slice a section of the bottom off the motor plate. Then, I am going to cut a piece of 1/4'' plate to the proper height, cross drill it with the same hole spacing as the current diff mount and thread it for M3, then weld it to the motor plate. Next, I will cut out a couple of tabs from 1/4'' plate, drill completely through them, and weld them to the motor plate at chassis level, then drill through the chassis to use a bolt at each tab. Finally, I will weld a thinner plate over the current hole for the outdrive in the motor plate, which happens to be the perfect diameter for the center diff bearing, and put a hole in the welded on plate just big enough for the outdrive to fit through but wont allow the bearing to go through, basically turning this into a center diff mount and motor mount with just 2 separate pieces. Simple, strong, effective, and should look cleaner than the current setup once it's done. I should have some progress on this by the end of the week or this coming weekend, so stay tuned for more updates, and as usual, comments questions, and more importantly, suggestions, are always welcome.

Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

|

|

|

(#7)

|

|

|

No Way....

Offline

Posts: 86

Join Date: Nov 2009

Location: France

|

03.08.2010, 03:35 AM

It's the NewEra tower, not really cheap, but very strong !!

thanks for the comment on my support, it's my first design...w/ google sketchup.... a friend gonna make it on AutoCAD, and after a another friend make it on CNC... it's AL of 6 mm , using M4 screw under the chassis, and I made a ...look a this (I don't know how to explain this in English... ) in blue it's a lexan sheet of 1 mm for protect the central diff..  I stay tuned ... and if you've got another vid'

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 3 (0 members and 3 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode