|

|

|

(#32)

|

|

|

Fat Kid Engineering

Offline

Posts: 3,634

Join Date: Jun 2009

Location: Hot as Hell West Central Coast Florida

|

02.03.2011, 12:23 PM

Sway bars on your Stampy;

See how the chassis has 2 tiny grooves just behind the front shock tower and the 2 empty 3mm holes. The grove is for the bar and hardware holes for the hold down screws. This should be behind the rear shcok tower as well on the diff case. Sway bar kits are readily availible via fleabay http://toys.shop.ebay.com/Toys-Hobbi...slash&_kw=sway |

|

|

|

|

|

(#33)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.03.2011, 12:45 PM

Given the terrible weather I have only managed 2 half pack runs. Still pimpin the 12c lipos, not doing too bad. It is 45 or so here and the packs have not gone over 100f. Nothing broken, yet.

Quote:

|

|

|

|

|

|

|

(#34)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.11.2011, 01:14 AM

Ok, so I have about 3 full packs runs altogether. And one broken rear driveshaft. Actually, make that 2.5 runs....

So I decided that the old pre-3.3 maxx driveshafts were the best bet. Real easy mod, except making the hubs hold 6x12 bearings... I really need to invest in a 12mm end mill bit. Any ideas where to get one super cheap, will only be cutting plastic with it in my drill press.. Anyways, I have one driveshaft done but cannot find anymore of the male splined sections. Have plenty of females, and some that look brand new. Anyone have any they don't want? |

|

|

|

|

|

(#35)

|

|

|

Fat Kid Engineering

Offline

Posts: 3,634

Join Date: Jun 2009

Location: Hot as Hell West Central Coast Florida

|

02.11.2011, 03:57 PM

Here ya go fruity pants, hope you can use one of these ??

http://shop.ebay.com/i.html?_kw=12mm&_kw=mill |

|

|

|

|

|

(#36)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.11.2011, 05:34 PM

Quote:

Will have to score one of those. I have only done on side rear driveshaft. We will see how it does. |

|

|

|

|

|

|

(#37)

|

|

|

Guest

Posts: n/a

|

02.12.2011, 12:18 AM

Well thanks, you convinced me. SHHH, don't tell Harold. I went ahead and bit the bullet, and bought the Tekno's all around. I just kept hearing good things, and the Maxx shafts are becoming a commodity. My Castle 3800 is on it's way, which I have different esc options if the Sidewinder can't cut it. But I'm gonna try a bec and cap on it first, maybe it will surprise me.

A little roller pic.

|

|

|

|

|

|

(#38)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.12.2011, 01:46 AM

Well, I blew up the maxx 2.5 slider tonight. About 4 mins into the 1st run. The yoke on the male slider just cracked and tore thru where the joint pin hole is.

I was doing some killer one wheel wheelies and landed on that wheels under full throttle. I think some heavy diff fluid in the rear diff will help, as that back tire was doing some serious rpm due to being off the ground. I do plan to use the 3.3 sliders next, probably use the center shafts from the nitro revo as they are shorter, a bit smaller, and should not require as much clearancing. Will be buying a 12mm endmill bit to mod the other carrier. Even though my "half assed" method works it is only 7 bucks shipped. |

|

|

|

|

|

(#39)

|

|

|

Guest

Posts: n/a

|

02.12.2011, 09:19 AM

I was looking at these Slayer shafts http://cgi.ebay.com/ws/eBayISAPI.dll...=STRK:MEWAX:IT The diff side is easy, just switch out to Revo outputs. But it seems like the axle end wouldn't work with any available axles, maybe you have a plan. When I get my Tekno's , which the rears use a bigger inside bearing 10x15 , like the front, I'm going to see if they can be milled out to use a 12 x 18 bearing, which would then allow the use of the complete driveshaft.

|

|

|

|

|

|

(#40)

|

|

|

Fat Kid Engineering

Offline

Posts: 3,634

Join Date: Jun 2009

Location: Hot as Hell West Central Coast Florida

|

02.12.2011, 11:14 AM

The FML shafts are super beefy but the price tag matches

|

|

|

|

|

|

(#41)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.12.2011, 01:00 PM

Quote:

You can replace the revo/slayer stub axle with the axles from the old maxx. Then all you need is a 6x10 bushing to fit inside of the tekno inner bearing. Already tried to figure out a way to use the tekno hubs to my benefit. May just buy a set and try, as that will be easier than just about anything else. |

|

|

|

|

|

|

(#42)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.12.2011, 03:52 PM

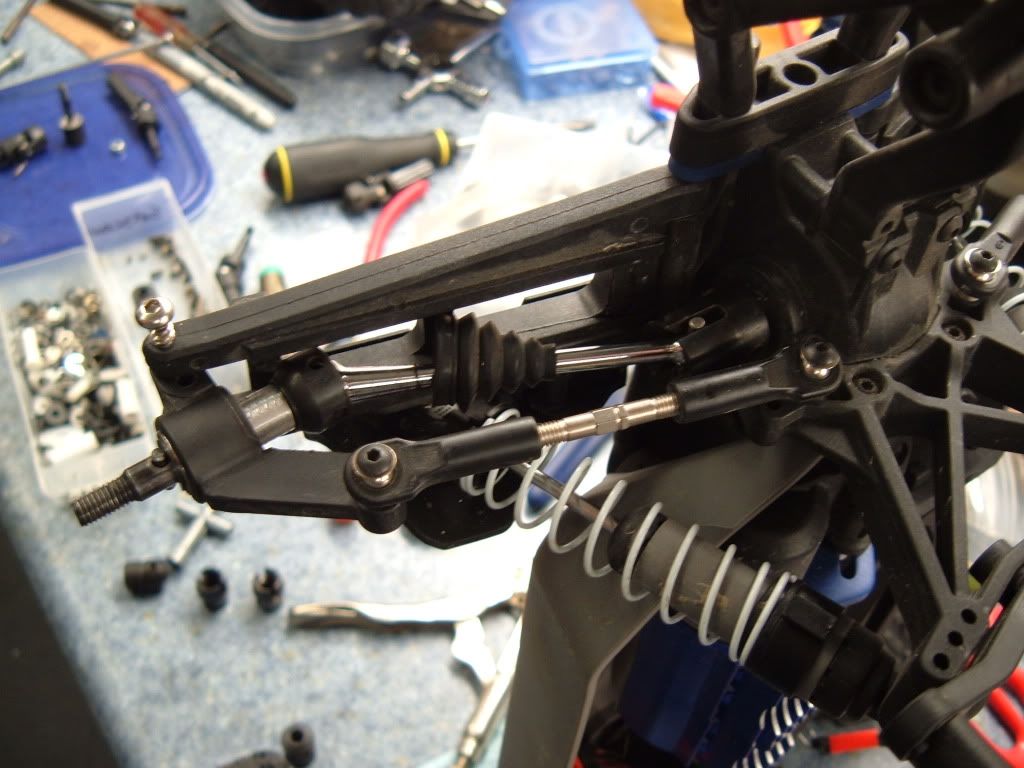

Ok, here are the destruction pics. The motor side rear diff output last all of 2 packs, and the other side rear output made it thru about 20mins more. The other shaft is the maxx 2.5 one that I grenaded last night. I replaced it with another just like it and we will see.

I also removed the rear diff and filled it with traxxas 50k diff fluid. Seems a bit better, does not go "one wheel" during wheelies as much as it used to. Now I did some tinkering with my selection of cvds. Since I have gone to 6x12 bearing I can run any cvd for an older maxx truck, but they will be too long. So i figured i would get a cheap "shiny" set of ebay, and cut them down. I have had good success with these cvds, I have them in the 6x6 maxx and they work fine. I have also cut/welded them before with good success. I would like to find an "off the shelf" option, so i will research that too. |

|

|

|

|

|

(#43)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.12.2011, 05:06 PM

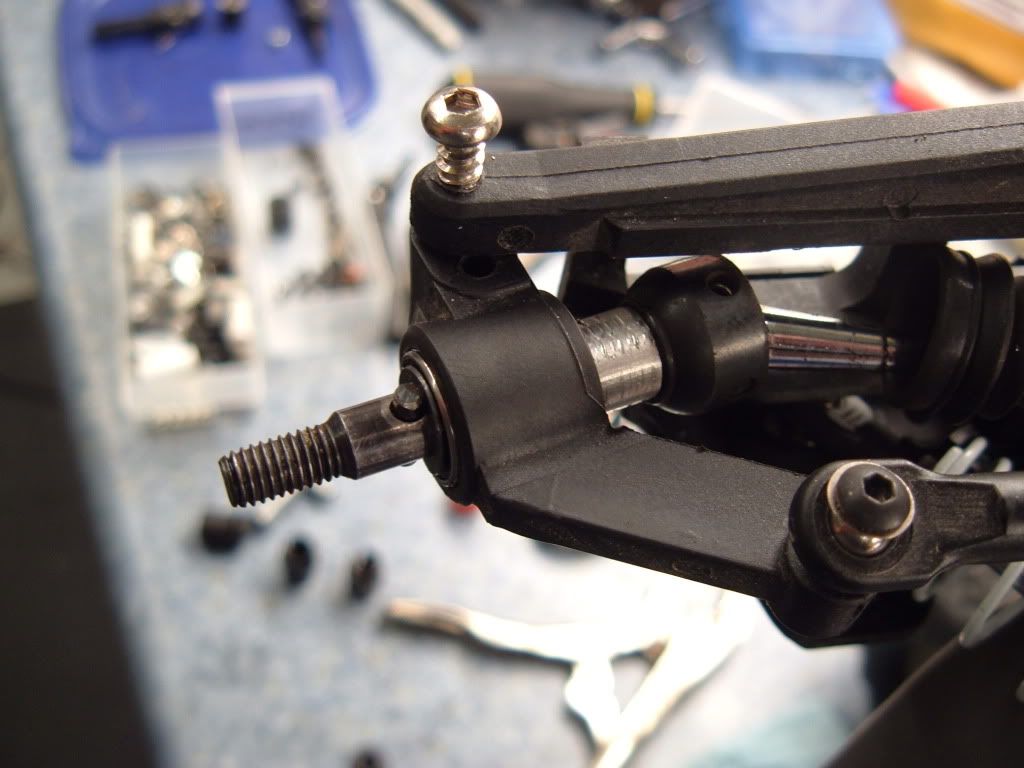

Ok, figured how to make a useable cvd setup.

Big mixture of parts here, I had all of it laying around. There may be a better way to do this, but I do not have the parts to make it happen at hand. So start by picking up a set of original emaxx center cvds : http://cgi.ebay.com/Traxxas-E-Maxx-1...item53de2b8356 And 2 lst axles, these are lst1 parts, the sliver and black ones have different handed threads, so one would be better placed on the right side and the other on the left, to keep the wheel nuts from backing off. I am not sure which is which but will check. http://cgi.ebay.com/LOSI-LOSB3503-FR...item43a15e64eb http://cgi.ebay.com/LOSI-LOSB3504-FR...item3ef83edcff Now the emaxx cvd shafts will fit with the lst axles. So well they must be exactly the same. You can even use the rubber boots that come with the maxx cvds, nice to keep the grease in. Now the lst axles are 6mm, so you will have to be running 6mm bearing and enlare the hexes to 6mm. And the lst axle is too long, so you need to make/find a 7.5mm long 6mm id spacer to slide over the lst axle before you put it in the hub. This places the axle pin hole just where you need it, and should allow for a traxxas 6mm id teflon washer to fit between the pin and the outer bearing. The spacer also places the dog bone end of the cvd the correct distance in the drive cup. Here is the issue, I tried a bunch of different loose drive cups that I had laying around. The ones that came with the emaxx cvd kit are too shallow, and the slots are not cut deep enough into the cup. They were 5mm id so the bolted up directly to the 5mm diff outputs on the stampy (kinda weird, as I though emaxx pinions were 6mm od, so the cups should have been that size?). So I tried a bunch more and found some diff cups from a no name brand of revo cvds. They are 6mm id, so you will have to swap the stampy diff outputs over to revo diff outputs (those are 6mm). So not optimum, but workable. And you end up with stuff designed for a much bigger truck, so they "should" last. I have had excellent success with the cvds that I linked, even though they are not name brand. Pics on the way. |

|

|

|

|

|

(#44)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.12.2011, 06:08 PM

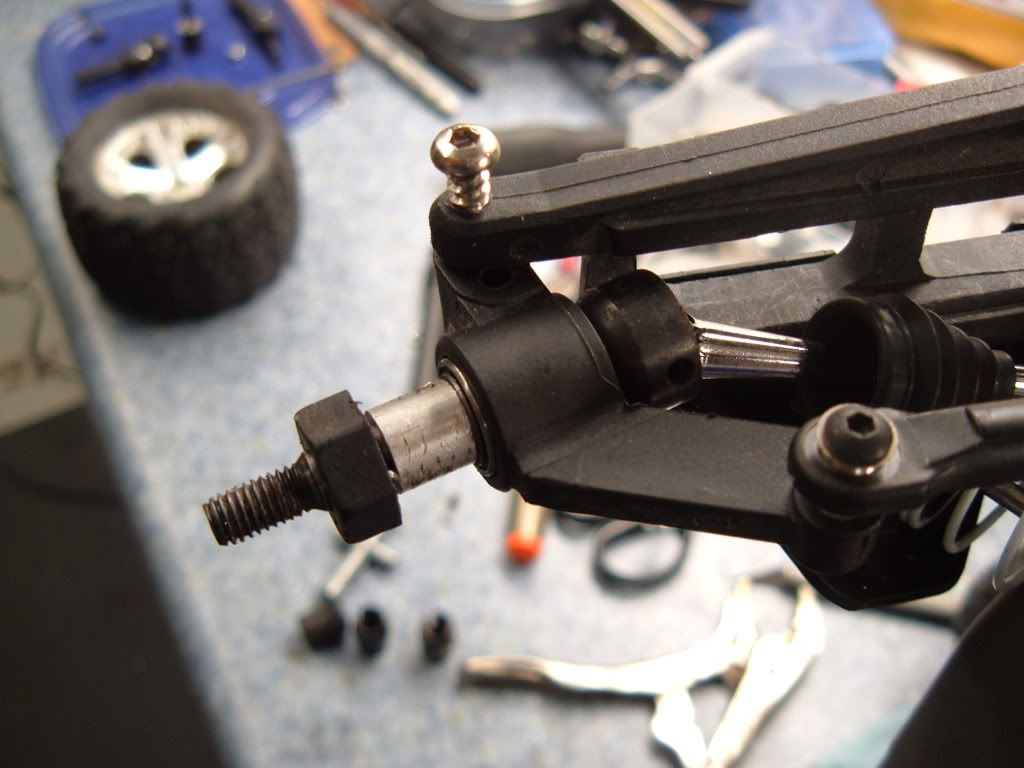

Picture time!!!

Ok, these show the lst axle with the spacer so that the emaxx center cvd will sit correctly in the revo diff output cup.    And these show the spacer on the other side of the hub, this will not work with the emaxx cvd, but if you had a 8mm longer cvd it would. I plan to cut and weld a lst cvd and use the lst axle this way. I can run a 2wd pede rear wheel (different offset to the 4x4 pede, as it uses 2wd pede front wheels all around) and give the other 2 front wheels i have back to my 1/7th scale pede based tube buggy. With the 8mm spacer on the outside the 2wd rear wheels have excatly the same width as the stock 4x4 pede setup. Nice how that worked out.   Not sure what to do with the front, but I think the stock sliders will be just fine. After the few packs i have run they are not worn or twisted at all. If they do crap out I will likely mod up some lst cvd/axles to work there as well. Or I could use old tmaxx cvd axles and the lst cvd shafts cut and welded. Here is a pic that shows the old maxx axles v/s the lst axle. As you can see the maxx axle is much shorter and the pin hole is closer to the cvd joint.

|

|

|

|

|

|

(#45)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.12.2011, 06:19 PM

Just in case anyone was wondering, the spacer I use was a cable stop that I found at the local hardware store. It is made of al, and is designed to be crimped on a cable, looks like the stock hole in it is about 1/4". All I did was drill it out to 6mm with a 6mm drill bit. It was just the right length, right at 8mm. Depending on how you mod your hubs to handle the 6x12 bearings you may have to sand some material off this spacer, or add a shim or 2. Fow me it was just about right, I removed some material so I could use a 6mm id traxxas teflon washer behind the axle pin.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode