|

|

|

|

|

(#1)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.06.2010, 10:10 AM

Been working a bit on it last couple days. Still acquiring parts also. Been really busy, and two small kids takes most of my spare time.

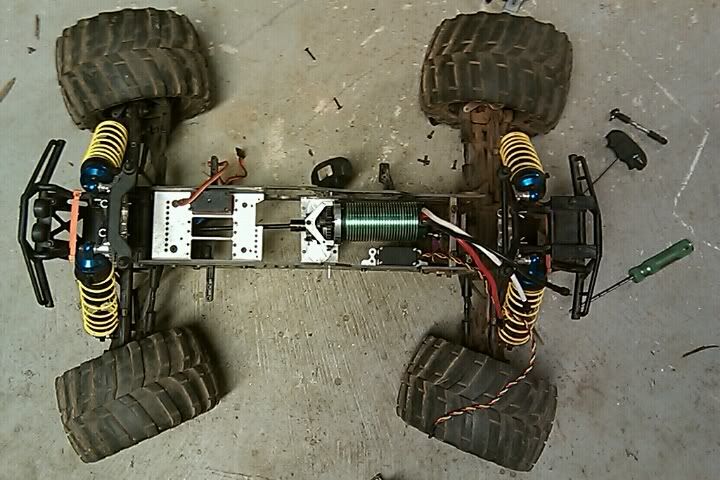

Anyway, I chopped up an old alu skid plate I had from an emaxx way back when. I wanted to build a little platform to mount the RCM UCD and the slipperential to start test fitting and getting an idea of how I want to do the ext tvps. One big trick will be to be able to fit the rear servo in there with the motor. The rear str rack requires a bit of room, and the servo has to mount high if its along the rail to allow for proper travel. I want to move the motor way back to hopefully have room in the center for batts. Getting everything inside the TVPS is going to be a pita. One note: I am using the 50T mod1 spur on the Slipperential. I had to file the hell out of the top plate to clear all the slipperential spur. Also, the tension ring for the diff is also large, so a lot had to be cut out for that to clear as well. I got the plate all done, then stripped the horrid blue ano.     Looks like I will need to offset the UCD in the final version to give clearance to the R servo. Plenty of room to do this. Only other issue I saw was that the CD sits up pretty high compared to the tranny outputs, so angles are more severe. The F bone will end up being quite long, so not so much an issue. The rear one isn't so happy tho, esp if I try to move it back even further from where it is. The cup was wanting to rub the bone already. I may have to drop the TVPs down and mount the whole thing lower. I don't want to give up too much ground clearance in the middle tho. A ~1cm drop makes the diff much happier. * I have on a cvd from my hyper st, as well as the rear XL dogbone. they just happen to fit perfectly. Eventually the F dogbone will have to be about 110mm longer... |

|

|

|

|

|

(#2)

|

|

|

n00b

Offline

Posts: 519

Join Date: Apr 2009

Location: The Netherlands

|

10.06.2010, 12:20 PM

I've also been drawing several sketches to fit a CD in my Flux with a 1717 / 1520. The higher output cups on the CD vs the standard gearbox make it a pita. Also because the LiPo's will have to be placed that much higher.

p.s. Is your ava Michael Jai White in Black Dynamite? |

|

|

|

(#3)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

10.07.2010, 05:20 AM

Quote:

Listen up jive turkey, dont forget to put a decent cutout under that slipper

|

|

|

|

|

|

|

(#4)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.06.2010, 03:42 PM

What kinda rundown is this, you jive turkey? Look man, I got to get back to the streets where I come from, sucka. I told you jive chops, I ain't no snitch!

HAHA! I typed that sh!t before I walked in the room! |

|

|

|

|

|

(#5)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.06.2010, 03:48 PM

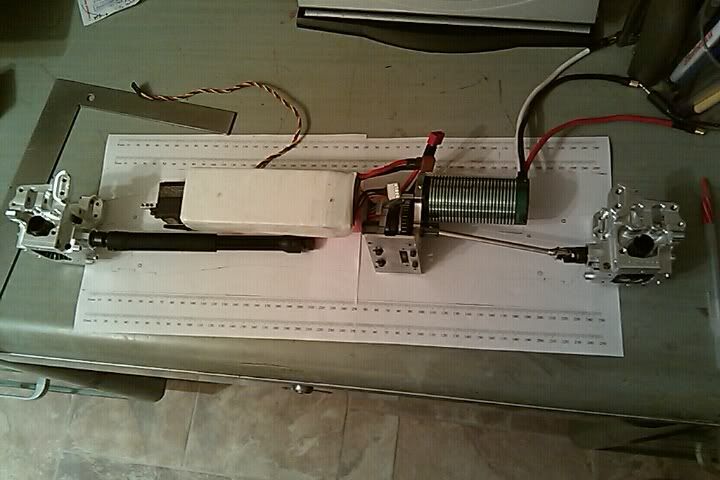

Made a rough tracing of the XL tvps w/ the screw holes I need to keep on a couple peices of paper. I'm then going to separate the pages, line them up, then fill in the middle section later.

I'll take that template and tack it to some thin pressboard so I can cut a couple sample tvps to work on the fitting and placements. Eventually I'll trace those back on paper and use that paper template on the alu tvps I'll cut. Only crappy part is my scanner only does max 14" width, so I have to make overlapping scans. I traced a few of the interior cutouts, but they are just in pencil on the paper. I won't keep them, but just for ref at this point. |

|

|

|

|

|

(#6)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.06.2010, 05:44 PM

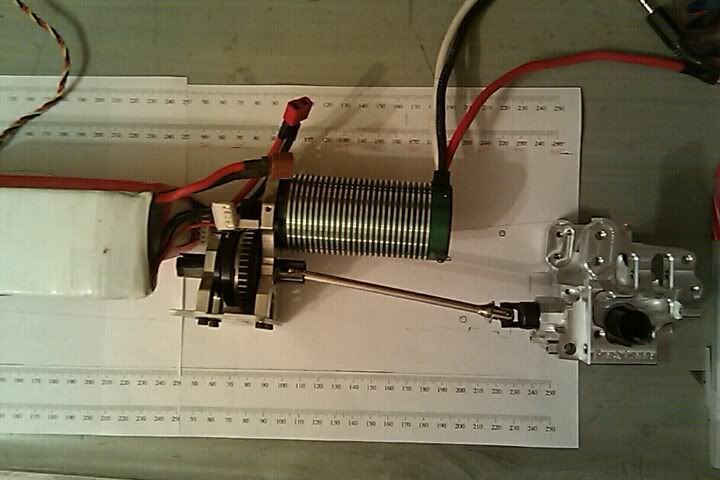

Slight revision to my idea. Made two pages w/ ruler markings and parallel lines all the way across. Pages were overlapped and tvp traced w/ essential screw holes. Pages were then split and scanned separately. The new pages are easier to line up on the ruler markings, so new wheelbase is just made by sliding the pages along to the intended measurement.

The wheelbase I am getting on my XL is ~412mm kingpin to kingpin. Strange as the listed wheelbase is 390mm. My target wheelbase is 520mm. I need to slide the papers back ~110mm. I made scans so I can just print these up, line them up and then overlay them onto my test material. I will need to trace out the new TVP design. The only critical areas are the screw holes and the bulkhead and skid plate fittings. Everything else is nego. |

|

|

|

|

|

(#7)

|

|

|

n00b

Offline

Posts: 519

Join Date: Apr 2009

Location: The Netherlands

|

10.07.2010, 07:40 AM

It's not possible without a lot of modding to fit a CD in my FLM FTC TVP's. Currently I'm just waiting on whatever FLM is coming out with, very anxious to see that.

In the mean while I played a bit with sketch up and got this:  It's going to be ~15cm longer than stock, so it's big :) I would like to make a wooden example of the TVP's for measurements and than perhaps make it in alu if I have / want to spend that amount of money on it. |

|

|

|

(#8)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.07.2010, 10:30 AM

Lol, yeah I cut a little slot for the spur. I wasn't going to post it, but the plate had a funny wtf face by the time I was done.

So I got the paper template laid out @+110mm. I laid down the bulkheads, servo and motor/cd to get a rough idea on the layout.    Even with the extra length. its still going to be pretty tight to get everything within the tvps. One bog challenge is going to be how to arrange the batts. Basically I got a few ideas. Easiest would be to make a batt box above the F driveshaft. It will sit pretty high tho. 2nd idea is to make saddle packs alongside the driveshaft, and fit them low in pockets. I was planning on HV anyway, so having twin packs is likely. The 3rd option is to lay the packs flat and low and build batt boxes to open outside the tvps, sorta e-revo style. Its a bit sacrilegious, and I'm not that thrilled about having to make secure doors to hold the batts. OTOH, it would give the best cg result. Eh.  The first option is the easiest, and with that CC motor sale, I have a very cheap 1717 and 1520 to play with. Its awfully tempting to just use those on 6S or so w/ the MMM. Plenty of power and performance with parts already on hand. Otherwise I'm waiting still for the HVMMM, and who knows when that's done, plus its more money to spend... I did look thru your pix _dV. You had some great ideas and layout. I like what you did with the str servos. That was another thing I was debating, how to mount the servos, as along the rail, the serov horn comes v close to the motor in the rear. I was going to turn them perpendicular to the tvps to clear more space for batts, but I may steal that idea if it doesn't work out well. Need to do it F and R, and its tight in back. |

|

|

|

|

|

(#9)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.07.2010, 05:14 PM

Had some more time to work today. Baby daughter has been sick, so had some time to work while she napped today. Got the tvp template transferred onto the pressboard, then cut it out with my bandsaw. Made quick work of it.

I doubled up two boards and screwed them together with the paper template screwed and taped in. Ended up needing minimal trimming to fit, mostly around the upper bulkhead connection.    Pulled the other tvp off the XL, and just bolted everything onto the new tvps.   So its not massive, but def bigger. Could use a bit of widening tho. 1" per side would be awesome, but parts just not there. I know FLM has a .5" widening kit, but its $$$, only 0.5", and alu. Hopefully the MBX6T parts come soon and everything works w/o too much of a pita. We'll see. |

|

|

|

|

|

(#10)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

10.08.2010, 07:09 PM

Quote:

Will be great to see some vid of it when finished. I enjoyed watching the vid of your previous 4WS build and its unusual look when turning. Btw, you might find that with the cutout you have for the slipper that rocks will get stuck under the adjustment ring as its diameter is much larger that of a normal center diff case. That's why my cutout is as wide as it is. |

|

|

|

|

|

|

(#11)

|

||

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.08.2010, 09:06 PM

Quote:

I'm glad you liked the vid. It was pretty short and crummy, but just something to show the 4ws in action. Meant to make another vid, but have barely drove it this yr. |

|

|

|

|

|

|

(#12)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.12.2010, 06:03 PM

I made a better template using acrobat. The one attached earlier is handdrawn and scanned. This one I added lines digitally to be sure they are square and they print darkly. You have to tell the printer to print comments for the lines to print. Kinda lame, but Adobe is teh ghey.

I may end up cutting another template with a shorter wheelbase. The bug body I want is really suited for 480mm wb and I'm worried it may be too long to look right, but IDK at this point. Since I may bail on the batts inside the tvps, there is not much point to the bit extra length. Prolly buy the body and compare the two templates before I make any cuts into my alu stock tho. |

|

|

|

|

|

(#13)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

10.07.2010, 05:58 PM

nothing some axle extenders couldnt fix :)

Looks like a great size... could you measure the wheel base from axle to axle please... It loos a very similar size to the DB-17 conversion maybe a tiny bit longer? |

|

|

|

|

|

(#14)

|

||

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.07.2010, 06:12 PM

Quote:

What I am hoping for is that the mbx6t arms work well, then I can use other offset truggy hexes to get me out farther. Least it starts on a good foundation. BTW, its ~510mm axle to axle. Almost extactly what an FG truck is |

|

|

|

|

|

|

(#15)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

10.07.2010, 06:32 PM

thats 3" over the DB-17! similar to the 5t conversion...

Maybe you want an extremely long truck, but i honestly believe that you will lose a lot of the nimbleness that this truck doesnt really have in teh first place... Would you consider bringing it down to aroud 18.5" axle to axle? it would still be huge but may be more fun to drive? Not telling you what to do, just thought i would give my 2 cents considering i see plenty of people with the 5t conversion going back to XL Length... |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode