|

Another LST XXL Conversion |

|

|

(#1)

|

|

|

Guest

Posts: n/a

|

Another LST XXL Conversion -

01.12.2011, 04:47 PM

Hi everyone,

After following MC's XXL build since the start i bought a XXL roller and converted it. It has gone through a few stages so i'll give you a brief history. To begin with i converted it by using the losi conversion kit. I had many issues with this kit but the main ones were the motor mount and the battery tray. After that i made my own battery tray and placed it between the tranny and the RX box/steering servo. For this stage i was still using the Losi motor mount. I then made my own motor mount out of 3mm thick ally angle. After this i lost interest in my XXL and thought about selling it. However i thought about MC's build and decide i would do a similar build myself. So over the past 4~6 weeks (thanks school hols) i made a somewhat custom chassis. I know that many of the ideas used for my conversion (if not all) are form other people but i'm not sure if someone has done a build exactly like mine. I will start to upload pics soon as i will copy them from the original thread on a different forum. This is the original thread if anyone wants to read pages and pages of random waffle. http://www.ausrc.com/forum/showthrea...XXL-Conversion Thanks, B-M |

|

|

|

|

|

(#2)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 04:56 PM

1st Stage

Motor: Losi 1300kv ESC: EZ-Run 150a Servos: Dual Ace 1015's

|

|

|

|

|

|

(#3)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 04:58 PM

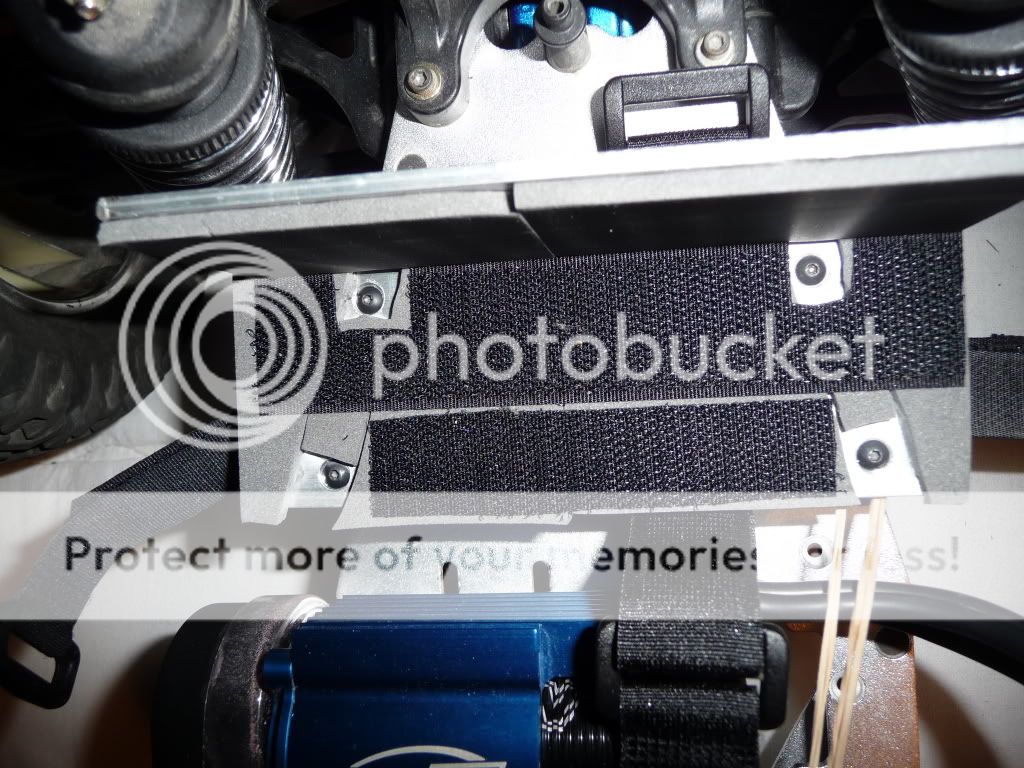

Stage 2

Custom battery tray Still using Mech brakes Motor: Tekin T8 1350kv

|

|

|

|

|

|

(#4)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:00 PM

Stage 3

Battery moved to between Tranny and RX/Steering servo If these pics are too big let me know and i'll change them.

|

|

|

|

|

|

(#5)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:01 PM

My custom motor mount

1st attempt - Right side 2nd attempt - left side

|

|

|

|

|

|

(#6)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:05 PM

Here is where i started to think about doing some serious stuff (well in comparison)

Below is a direct copy so some thing may not make sense on this forum. ------------- well i have scrounged enough money from nearly everywhere to buy what i wanted. This means that i no longer 'need' to sell my LST XXL. So here is what i have been thinking. I could try and convert this into a somewhat truggy. Or at least lower the ride height, get some smaller and better tires and wheels, buy a better motor mount and play around a little bit more with gearing. For wheels and tires i am thinking that maybe some normal 40 series will be ok. I have enough 40's that i could run for about the next year without having to get new ones. For the motor mount i am thinking about getting a rc-monster revo comversion motor mount. Apparently it is a universal mount and will mount onto any nitro mounting holes. If i can find a place to get some decent sheet metal from i might try and make my own chassis and have it as i near complete custom build. I think though if i were going to do that i might need to sell my g-maxx. Hey LD, do you regret selling your e-maxx or not. I am just a little worried about selling it as i might regret it and it'll cost me a friggin fortune to make another like it, especially as the chassis i used has been discontinued. |

|

|

|

|

|

(#7)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:05 PM

Another direct copy

--------------- well i just ordered a 2.5mm thick/thin sheet of CF. This will allow me to go through with my plans. Here is what i had in mind. Get rid of the tranny and install a CD using this mount LINK I will mount the CD on the lower chassi plate which i will make out of CF or 6061-t6 aluminium. For the batteries i will either mount them on the lower chassis plate by extending it past chassis rails or i will use some savage flux battery trays and mount them to the side of the chassis. For the upper plate it will have about 2 holes. One for the CD and motor and another for the servo and that is about it. To give it a lower stance i will try and get hold of some muggy towers as they make the shocks less vertcal and a little more horizontal. i have already ordered the 17mm hexxes and the wing mount so now i'll try and figure out how i' gonna do this. God i love school holidays. before i got into RC i would spend most of the hols inside watching tv and doing nothing. now i want to wake up earlier so i can go tto the shed and work on stuff/run my cars/ get out of the house in general. Plus by making all of this stuff myself i am learning how to do things rather than learn them when i'm in uni or something like that. Anyway that is my little rant of the day. --------- i might also try and do something like this to my e-maxx/g-maxx and use a CD rather than a tranny to lower the CG. my inspiration http://rc-monster.com/forum/showthre...=19881&page=26 http://www.rc-monster.com/forum/showthread.php?t=26070 http://thetoyz.com/forums/index.php?...hl=lst%20muggy and heaps more |

|

|

|

|

|

(#8)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:09 PM

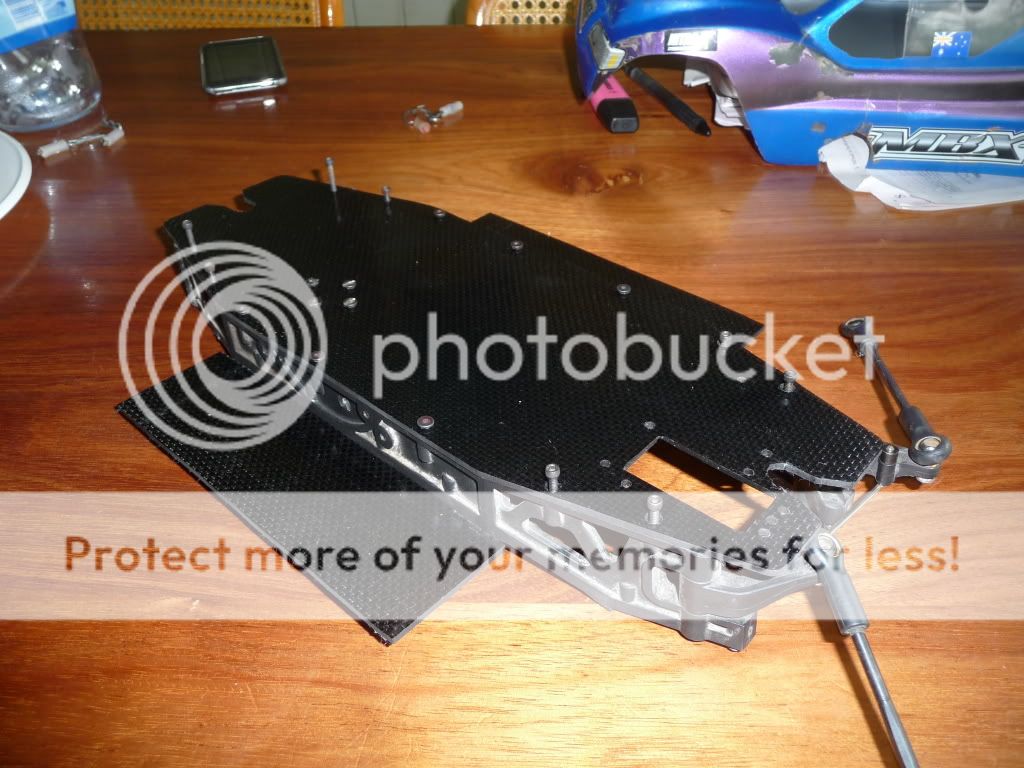

The start of the mock-up chassis

The batteries pictured are 4s 5000mah lipo's ------------- more inspiration http://www.rc-monster.com/forum/show...=25581&page=15 |

|

|

|

|

|

(#9)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:11 PM

Another copy

----------- hey, for the motor mount i will get the one where the motor mounts above the CD. As for the racing issue, i reckon i could get away with it as i can lock the diff and then if they say it doesn't have a tranny i'll just get another diff and diff mount and have the pinion driving the CD then that CD driving the other CD. I could then just put a 5hitty plastic case over it and say it's a transmission. Also i doubt i'll be racing this at proper events as it won't hold a candle to the e-revo's. I will have this for bashing and racing if i get bored of the e-revo. I am hoping the CF gets here tomorrow or friday so i can work on it over the weekend. Though everything is on hold till i get the CD mount which is currently out of stock. Also with this build i'll have to get some custom dogbones or get some extended diff cups. All of the stuff pictured above will be redone with CF. 2.5mm thick. The stock chassis is very weak and i would say not even tempered so i think the side rails are the backbone to the kit and give it most of it's strength. I havent ordered the alu yet as i might change my mind and get the 1/10' stuff as it's roughly the same thickness as the stock chassis. For the alu though i am sorta thinking of doing the lower centre plate with that or do a brace for the CF with that. This project is going to take a while and most of that will be waiting and thinking about how to do stuff. |

|

|

|

|

|

(#10)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:12 PM

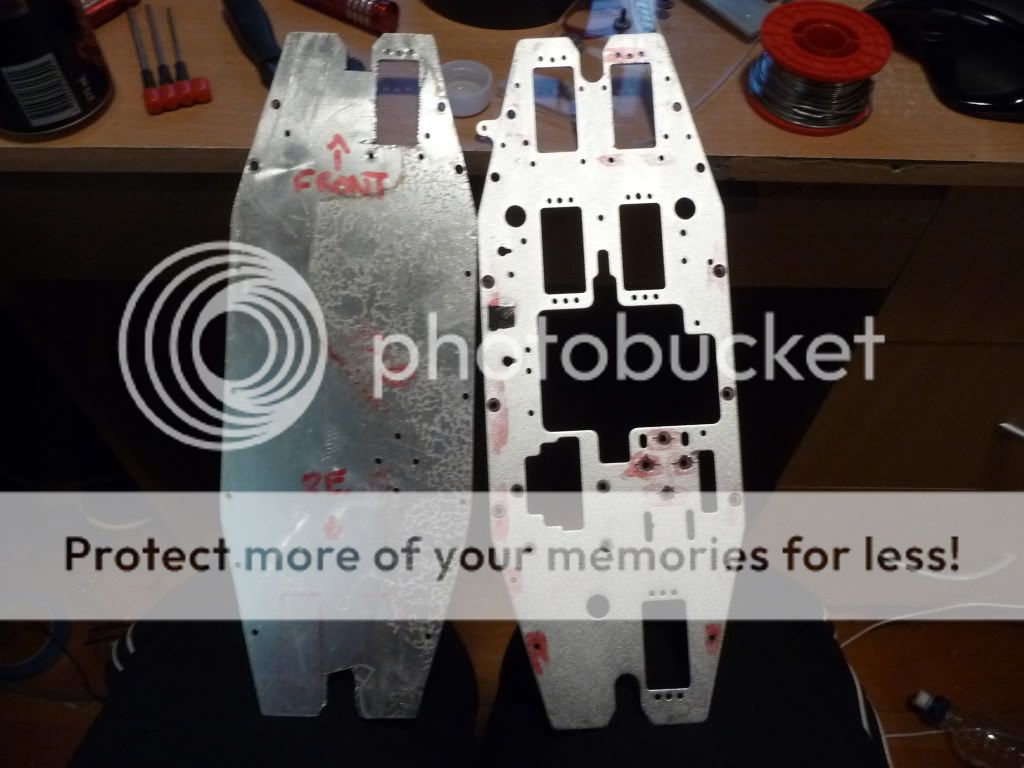

Got my cf sheet in 2.5mm 450mm x 500mm

here are some pics. have a look at the lower part of the sheet in the 2nd pic. I'm a little unhappy with the finishing job on the edges and how the weave goes crazy towards to bottom.

|

|

|

|

|

|

(#12)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:14 PM

Another copy

------------- I actually don't mind doing some of this custom fab stuff. I would of done shop/tech a/furnishing except you have to do what the teachers want not what may actually be of benefit to you. The only thing that annoyed me is that i don't think i stopped all the CF dust. I'm not sure if i inhaled any but if i did it wasn't much and hopefully it won't kill me...seriously. i really cant wait till the universal diff mount comes back into stock at RCM. Who knows i might just use the CD mount from my STe as it will give the car a lower stance and might look a little cleaner. --------- Now i have a few questions. 1) I am going to try and change some of the screws to metric as i hate imperial. So should i use countersunk screws and countersink them or should i use button head screws. ATM i don't think i need to have the upper plate completely flat so button head screws might work but i was wanting some other peoples opinions on this matter. 2) i want this to handle well when i finish it so i have 2 possible set ups. 1) mount the batteries on the side plates/wings and use a CD mount that has the motor on the same level as the CD.(like normal BL conversion mounts. (lower CoG) 2) mount the batteries on the upper plate and have a CD mount that has the motor above the CD. (higher CoG but closer to centreline of chassis) 3) should i reinforce the lower chassis plate with some 6061-t6 2.5mm aluminium? 4) should i use a CD or should i try and use a proper tranny like an e-revo/e-maxx one? ---- i think that's it for now but i'm sure i'll have more soon. |

|

|

|

|

|

(#13)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:15 PM

Another copy

--------------------- I used the metal blade. It worked very well but unfortunately some of my cuts are a little wobbly. For the motor i am think a tekin 1700v combo. Mainly coz that's what i as using before and it was working well. I also have no other motors spare other than the 1717 but i don't think that'll fit. Ok, i'm gonna go with the upright CD mount. once i get that installed i will look at how i am gonna place the batteries. I could go with them on the wings or on the upper plate either side of the motor. I'd have to have a look at how much room i have after i put the CD in. With the driveshafts i will try and get the front one to work by placing the CD towards the front but for the rear one i'll need a custom one. Thankfully i can get them from RCM as well but i can't order it till i get the CD mount which is out of stock ATM |

|

|

|

|

|

(#14)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:16 PM

Another copy

---------------- just tried to fit a PL bulldog truggy shell on it. If i have the batteries vertical (on their side) on the wings the body will fit if i squeeze it over, so it definately wont fit if i use the flux battery boxes. However, if i use the upright CD mount i should be able to have the flux boxes lie on their side on the upper plate. This will of course raise the COG but make the weight more towards the centreline. I think that is what i'll do. I should be getting the flux boxes tomorrow (thanks towie) and i'll see how they fit. But once again i am not gonna cut into the mock chassis until i get the CD mount let alone the CF chassis. I think for some of the screws i will have to countersink them as to have a flat chassis. Also i need some muggy shock towers and lower shock mounts. RCH have them listed on their website but seeing as the muggy is no longer available parts have dried up. The only thing i am a little unsure about is the rear dogbone. I will need to find one that is the right length or get one custom made. not sure how long that is gonna take and once again i cant sort that out till i get my CD mount. This weekend will not be a good one for me. I have my moogen but not the conversion kit, i have my XXL ready for the CD but no CD mount, and my hyper 9e that was supposed to arrive today didn't. Just a question to anyone in brisbane -> By any chance does anyone have a router table that they are trying to sell as this may make making parts out of CF much easier. If i can't get a router table i might just send the other bits and pieces i want made out of CF to carbonfiberaus as they have a CNC service but i reckon the price would be ridiculous. Hey LD if this works out and works well might you try and do the smae thing. I've been thinking about it and if i can get CFA to CNC some chassis' i could sell them. This probably wouldn't work out though. |

|

|

|

|

|

(#15)

|

|

|

Guest

Posts: n/a

|

01.12.2011, 05:19 PM

Another copy

=================== Just got some 17mm hexes and a set of flux battery boxes. These boxes are HUGE. I'm now not sure if i'll have a choice of placement as if i try to put them on the upper plate they will hit the front and rear assemblies. But once again i can't do anything till i get that damned CD mount. ============== ust finished doing the countersinking. I need to do it incase i have my batteries on the upper plate. ALos while at bunnings today i got a dremel router attachment. What it does is uses your dremel and turns it into a bench router. this means that it'll be much easier to replicate metal items on the XXL. ============== retty good. I bought a few different bits. the first one i tried was useless though i didn't know that until i got sick and tired af having to apply soo much pressure. I then got a different bit and it was excellent, there are only 2~3 screws that make a little bump. just put the front and rear ends on the chassis. everything lines up perfectly which is good. I then decided to test fit the body. The bottom of both sides of the body don't touch the lower plate. This could be resolved if i can get some muggy shock towers. I'll put a thing up in the wanted section. For the battery placement i am rethinking my idea of using the flux battery boxes as they are too long. I could just chop them up and then join them again somehow. If i think that'll be too hard i will just make my own using some angle alu, pick some up at bunnings today. Or i could get some propper battery boxes and use them. I'm not sure as i don't know how much room i have to work with ATM due to no bloody CD mount. HURRY UP RCM AND MAKE SOME MORE. I put some 40 series wheels and tires on and it looks wierd. the tires and wheels look so tiny against the XXL body. Though if i can get some muggy towers i can lower the body or use the bulldog one. this build is moving my XXL from the MT side of things to the truggy side. It's having a sex change as some might say... ============= I'm back to having conversations by myself...jks Today i cut some more bits out of CF. I did these by using my dremel router table attachment. It hakes it much easier to cut things that have weird shapes. PICs

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode