|

|

|

|

|

(#1)

|

|

|

2 KiloWatt RACER

Offline

Posts: 2,496

Join Date: May 2007

Location: Houston

|

12.14.2009, 10:06 PM

aargggh, mine is not here yet.

GTP-Pletty Big Maxximum+RX8. GTP-C50-6L Hacker+RX8. CRT.5-Pro4+ZTW esc. 24s2p EVG SX 49.6mph Ebike. 18s4p Raptor 60mph Ebike. 11.5KW |

|

|

|

|

|

(#2)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 368

Join Date: Feb 2009

Location: The Town, CA

|

12.15.2009, 12:03 AM

Got mine 2 days ago. Definitely want to look into overcoming the 6mm obstacle and using it on my Muggy.

|

|

|

|

|

|

(#3)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,609

Join Date: Aug 2008

Location: Bozeman, Montana

|

12.15.2009, 12:34 AM

I bought a 3" pocket stone (coarse, of course) from Ace hardware and permeated the thing with 3-in-1 oil, hooked up the 1717 to my MMM, and held it at full throttle for short bursts while I pressed the stone into it. I only do short bursts and then stop to let it cool but so far I've been at it for 2 hours and still have some grinding to do before it's done. I tried a magnet and a paper towel but nothing seemed to be able to keep all of the metal shards out of the front bearing and now it's making a bit of noise. I've been cleaning it out and flushing 3-in-1 oil through it but I suspect I will need to replace it

Why oh why couldn't they give us a 5mm shaft.... Why oh why couldn't they give us a 5mm shaft....

|

|

|

|

(#4)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

12.15.2009, 12:46 AM

Quote:

I am really not looking forward to doing this when my 1717 comes in... |

|

|

|

|

|

|

(#5)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,609

Join Date: Aug 2008

Location: Bozeman, Montana

|

12.15.2009, 01:44 AM

Hmm, that could work as long as the friction between the shaft and the bag isn't too much. I am ordering a new bearing anyway, by the time I got the shaft ground to the point that I could get the pinion far enough on the front bearing was seriously jacked up. I measured it at 6x16x5, shouldn't be too tough to find...

|

|

|

|

(#6)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

12.15.2009, 01:51 AM

Looks like Mike is gonna have to start making some Mod1 and Mod1.5 pinions with 6mm bores. Turning down the motor shaft sounds like too much of a PITA IMO.

|

|

|

|

(#7)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,609

Join Date: Aug 2008

Location: Bozeman, Montana

|

12.15.2009, 02:16 AM

It is a major PITA. Took me about 3 hours, a lot of patience, and wore through part of a grinding stone. Should prove to be a very good shaft, judging by what it did to my stone

|

|

|

|

(#8)

|

|

|

RC-Monster Aluminum

Offline

Posts: 972

Join Date: Feb 2008

|

12.15.2009, 04:49 AM

I can re-size your motor shafts. pm me.

It's worth it!  1717 6s 1717 6s The 1717 stayed under 90*F pushing 10-12lb in loose stuff geared 50ish! I think I was pegging it on 4s, on 6s I ran out of space real quick. No hot wires, no hot lipos, MMM's fan ran for 20 seconds after stopping. |

|

|

|

|

|

(#9)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,609

Join Date: Aug 2008

Location: Bozeman, Montana

|

12.15.2009, 02:53 PM

What did you use to trim yours down? Looks like it should be an excellent MT/heavy truggy motor, once we get a 5mm shaft

|

|

|

|

(#10)

|

|

|

RC-Monster Aluminum

Offline

Posts: 972

Join Date: Feb 2008

|

12.15.2009, 03:22 PM

Dermil with the cut off wheel & sanding drum, motor in a mount, heat shrink tube cut short and layered up a bunch on the shaft to cover the bearing, magnet, zip lock, set transmitter end point to med-slow motor rpms. I used a 4s for grinding power but 2s,3s would have safer no load rpms. Zip lock did kind of suck, it would grab and try to twist up around the shaft, unless the hole was to big to do much anyways, but it kept the dust of the rest of this beastly motor. Then just stroke the shaft nice and easy. I held the cut off wheel rotated about 30* from axis of the rotating shaft to help maintain squareness.

|

|

|

|

|

|

(#11)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,609

Join Date: Aug 2008

Location: Bozeman, Montana

|

12.15.2009, 03:32 PM

The sanding drum was enough to trim the shaft down to 5mm?

|

|

|

|

(#12)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

12.15.2009, 03:51 PM

I have a technique that I plan to try.... I will set it up and take some pics.

|

|

|

|

|

|

(#13)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

12.15.2009, 05:50 PM

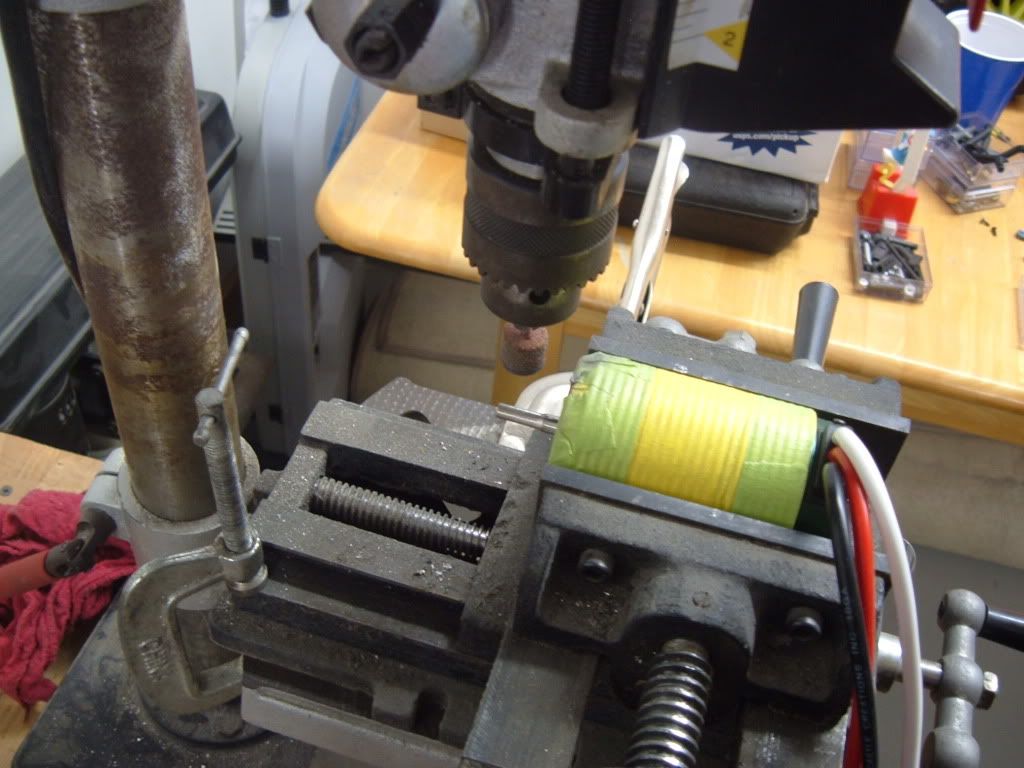

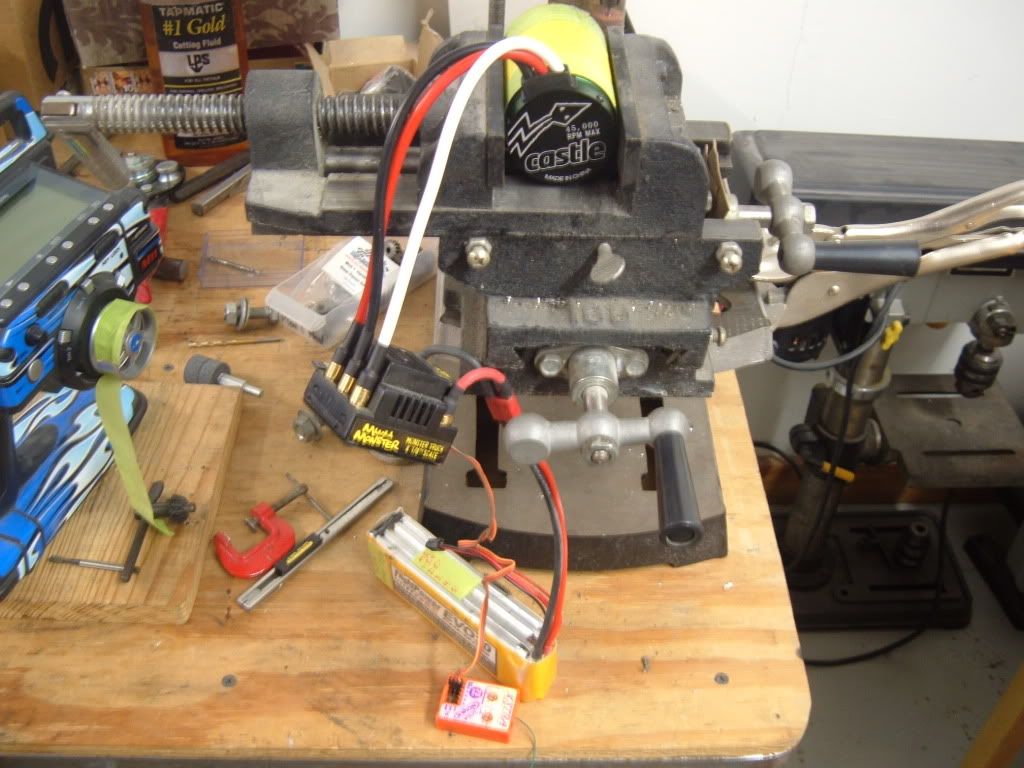

OK, here we go.

So I used my drill press, 2 axis vise and some dremel and larger grinding stones. Took about 20mins, and that was with me constantly checking it and letting it cool. Pics tell the story.

|

|

|

|

|

|

(#14)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,609

Join Date: Aug 2008

Location: Bozeman, Montana

|

12.15.2009, 06:11 PM

That came out clean! 20 minutes has me jealous, I was grinding on mine all night.

|

|

|

|

(#15)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

12.15.2009, 06:16 PM

Quote:

Now I get to reassemble the lst and give it a try. I also have to make a tray for the zippy 5k 40c 6s pack... Maybe this weekend... No time. |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode