|

|

|

(#16)

|

|

|

RC-Monster Mod

Offline

Posts: 6,597

Join Date: Apr 2007

Location: NJ

|

08.06.2009, 09:37 AM

Ahh maybe nows a good time to unload my spares :)

|

|

|

|

|

|

(#17)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

08.06.2009, 09:54 AM

|

|

|

|

(#18)

|

|

|

RC-Monster Mod

Offline

Posts: 6,597

Join Date: Apr 2007

Location: NJ

|

08.06.2009, 10:11 AM

Brian - sometimes you get "creative" just because - FYI bit small but the S is in stock...

I'll check tonight but think I have a spare really rare, highly sought after XL at home that I could sell. |

|

|

|

|

|

(#19)

|

|

|

Z-Pinch racer

Offline

Posts: 3,141

Join Date: Nov 2006

Location: SK, Canada

|

08.06.2009, 01:31 PM

Brian, I used CA glue to glue the endbell back on a 540C 7XL motor because the the threads were stripped after the cover got knocked off after a crash.

Anyways, I tried to turn the endbell off, it doesn't budge.

|

|

|

|

|

|

(#20)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

08.06.2009, 01:56 PM

Well, for threaded endcaps, that might be fine, but the Medusas are just press fitted.

|

|

|

|

(#21)

|

|

|

Guest

Posts: n/a

|

08.06.2009, 04:44 PM

I had used little screws for my endbell on my 36-60-2000 in my E-revo. Unfortunately eventually one did break out the motor can. I probably could have had the hole a little further away from the edge. But it was caused from a 20 foot, double backflip rear dive . Sane people should be alright. I just electrical taped it after that, the 1 screw and tape held out.

|

|

|

|

|

|

(#22)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

09.07.2009, 01:50 PM

Just an update: I found an extra tiny screw so I added it to bring the total to 3 screws. And when I took it apart, I found the red locktite didn't hold too well (so much for locktite tech support). So, I used JBweld after all.

And for the ultimate test, I bashed the heck out of the XT8 and everything held up. Play was stopped by an obliterated rear diff case (the part that attaches to the chassis, shocktower, etc). |

|

|

|

(#23)

|

|

|

RC-Monster Aluminum

Offline

Posts: 610

Join Date: Feb 2009

Location: Tomball/ Houston Tx.

|

09.07.2009, 02:34 PM

I didn't think that red would hold that's not its purpose. The green sleeve retaining compound will hold. It's still holding up on my motor. They also recommend using the primer before using most of their products. I haven't used it before except when I worked for Western Atlas where it was part of the procedure.

Using Loctite is just like anything else it has to be used properly if the surfaces are not completely clean and free anything but the substrate you are attaching it won't bond. If there is any oil at all it won’t set. Anodizing needs to be removed and both surfaces roughed up for it to work, same with JB weld although I have yet to find anything that it is good for. At least it never works where I need it to. Jeff |

|

|

|

|

|

(#24)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

09.07.2009, 02:38 PM

When I applied the JBWeld, I did take off all the anodizing and roughed it up with a dremel sanding wheel. So, that coupled with the screws should hold.

|

|

|

|

(#25)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 225

Join Date: Sep 2008

Location: Suomi Finland Perkele

|

09.07.2009, 02:56 PM

When you opened it up, did you notice that it didnt have any shimms?

|

|

|

|

|

|

(#26)

|

|

|

RC-Monster Aluminum

Offline

Posts: 610

Join Date: Feb 2009

Location: Tomball/ Houston Tx.

|

09.07.2009, 03:10 PM

It will probably hold on the end bell, but if it let go on the front it might hold for a little while. When I got my Faegiao the end bell was already popping off. My biggest problem was that the front one came off in a nasty crash. After that was when I decided to use screws to hold it in place. After checking it while bashing I noticed the motor was "loose" so I took it back apart and used a dremel with the wire wheel to clean it then reattached everything and added the green sleeve retaining compound. (there are several Green compounds most are low strength threadlockers). Let us know how it stands up.

Jeff |

|

|

|

|

|

(#27)

|

|

|

Brushless Basher

Offline

Posts: 59

Join Date: Apr 2009

Location: Adelaide South Australia

|

09.08.2009, 09:38 AM

I use red loctite on my pinions a little heat from a soldering iron on the shaft and they pop right off - no good for the end bell. Can someone tell us aussies

what this JB Weld glue is |

|

|

|

(#28)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 225

Join Date: Sep 2008

Location: Suomi Finland Perkele

|

09.08.2009, 12:02 PM

Quote:

Its one of those two component glues. I will stick with Loctite 603, i have stuff that is meant to secure bearings, that should be realy nasty stuff and should hold... |

|

|

|

|

|

|

(#29)

|

|

|

RC-Monster Aluminum

Offline

Posts: 610

Join Date: Feb 2009

Location: Tomball/ Houston Tx.

|

09.08.2009, 09:36 PM

JB weld is a 2 part epoxy and is one of the most widely known here in the US. There are tons of different 2 part epoxies around here. I think there are a lot better ones out there but some are just worthless. I have had good luck with some of the stick epoxies that you kneed together but it wouldn't be right for this application.

603 is a good, there are really a ton of different compounds that will fit this application there are ones for bearings (like the 603) and ones for loose or worn out bearings (really) I think the tolerence on that was .025" (.5mm). You can find this stuff at industrial bearing suppliers, but look up what you want first, because most might not have it in stock and they will try to sell you "something close". Jeff |

|

|

|

|

|

(#30)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 280

Join Date: Apr 2008

|

09.10.2009, 11:26 AM

Wow, I haven't been on here for ages! Helps to have a PC that works too.

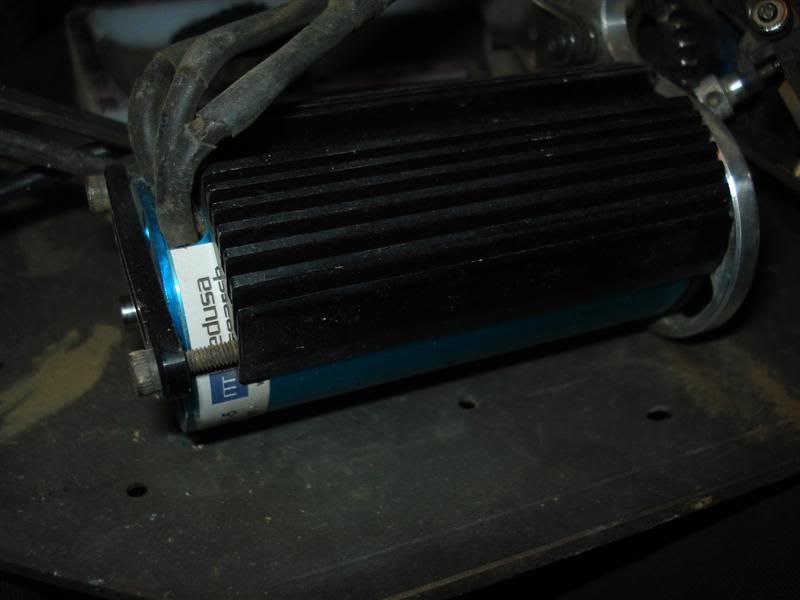

Here's my Medusa. Will I have trouble with the endbell separating from the can?

MP7.5 Kanai III Tekno Neu 1515/2.5D 1700kv MM 4S LST 2 Carbon CC 1717 1Y 1580kv MM 6S Futaba 3PKS Spektrum Pro |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode