|

|

|

|

|

(#1)

|

||

|

WARNING: May become violent.

Offline

Posts: 2,426

Join Date: Mar 2007

Location: Wisconsin

|

01.14.2009, 10:59 PM

Quote:

Lamborghini's= True Engineering Marvel's |

|

|

|

|

(#2)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

01.22.2009, 01:22 PM

Upate-

Have been running the truck lightly for a while, the rcm lipos are doing great! I couldn't ask for more...(or could I) The motor has yet to reach 125 degrees. I replaced the ball ends on the truck with offset ends to match my 0 offset rims..trouble is that I neglected to make a note of the turnbuckle length, so now my truck has about 3 degrees of toe in instead of out  . Also broke my wing mount and my my battery tray ends while running with Eovnu the past weekend.. The story to the battery trays goes as follows. I was just zipping up and down the street and Mike(eovnu) let his girlfriend drive his hyper 7- he told here to drive the car to him so he could check something, all was well and she decided to floor it in reverse.... headed strait for me.. I jumped to avoid the car while cranking my steering wheel to the right on my m8. The cen went flying into a curb at about 20mph... blew the front battery stops right out. . Also broke my wing mount and my my battery tray ends while running with Eovnu the past weekend.. The story to the battery trays goes as follows. I was just zipping up and down the street and Mike(eovnu) let his girlfriend drive his hyper 7- he told here to drive the car to him so he could check something, all was well and she decided to floor it in reverse.... headed strait for me.. I jumped to avoid the car while cranking my steering wheel to the right on my m8. The cen went flying into a curb at about 20mph... blew the front battery stops right out.So I have a little bit of rebuilding to do. My time is limited as its FIRST Robotics "build season" where we work everyday after school till 6, then weekends 8-5. Right now i was experimenting with our teams hand lathe, making a center spool for Mike's hyper seven. If you have seen my other thread, you know that i have been having motor mount troubles. My 1/8"2x2 aluminum angle mount is starting to deteriorate and flexes ALOT!, I noticed it when I would yank the trigger the gear sound would change(loading up) then die back down once the truck stopped accelerating. The solution seems to be a 3/16th" 6061 aluminum mount off the center diff, tied into the main chassis. Im probably going to make that today. Sorry for being long winded :) R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

Carnage Pics |

|

|

(#3)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

Carnage Pics -

01.25.2009, 04:42 PM

Replacing the Arm as we speak, no spare wing mount though  More pics in a few. R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#4)

|

|

|

RC-Monster Spudgunner

Offline

Posts: 2,353

Join Date: Apr 2008

Location: South Dakota

|

01.25.2009, 04:50 PM

You don't need a wing anyway...

|

|

|

|

(#5)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

01.25.2009, 04:51 PM

R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#6)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

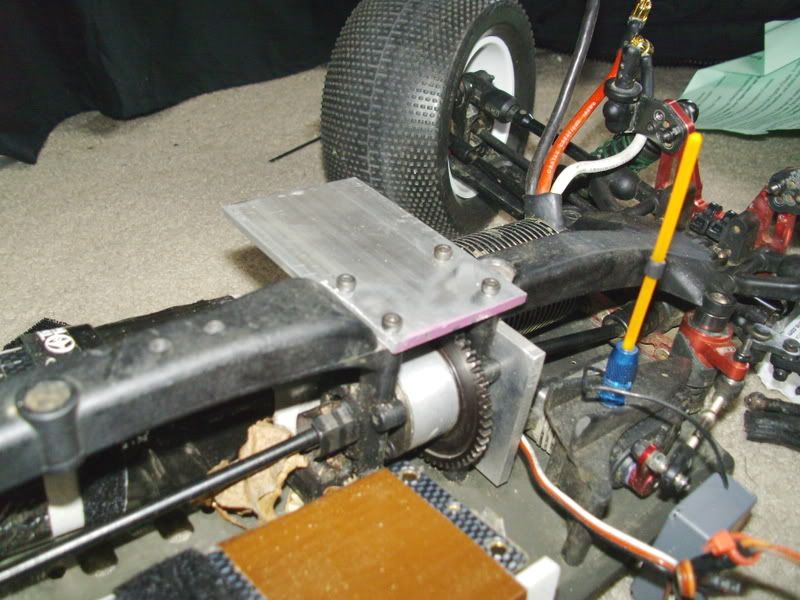

01.25.2009, 05:07 PM

New Rx/esc plate

R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#7)

|

|

|

RC-Monster Spudgunner

Offline

Posts: 2,353

Join Date: Apr 2008

Location: South Dakota

|

01.25.2009, 05:16 PM

Did you attach the motor mount to that esc plate? You should.

|

|

|

|

(#8)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

01.25.2009, 05:23 PM

No, it replaces the center plate that is usually there. no need to attach it to the motor mount.

R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#9)

|

|

|

WARNING: May become violent.

Offline

Posts: 2,426

Join Date: Mar 2007

Location: Wisconsin

|

01.25.2009, 05:23 PM

Very nice.

Lamborghini's= True Engineering Marvel's |

|

|

|

(#10)

|

|

|

Dsm needed

Offline

Posts: 656

Join Date: Sep 2007

Location: Queensbury

|

01.25.2009, 06:33 PM

Nice Ben, now wheres the turkey bar?

|

|

|

|

(#11)

|

|

|

A 16yr old with a combover

Offline

Posts: 636

Join Date: Sep 2008

Location: Mount Holly, NJ

|

01.25.2009, 11:59 PM

thats karma for u ben

he decided to rape my hyper when it only had 3 wheel drive, and flipped it over, then drove over it multiple times... then he ran into a light pole abut a minute later and broke the arm! btw it wouldve been cooler if u put the rx under the mmm on the plate or put the plate at a 45 degree angle |

|

|

|

(#12)

|

||

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

01.26.2009, 07:43 AM

Quote:

just hope it will fit under the new body.. R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

|

(#13)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 354

Join Date: Sep 2008

Location: Hamburg, Germany

|

01.27.2009, 06:00 AM

you shoult connect the mount with the chassis, with a bracket:

like that you have -no flex at all -the chassis turns into a heatsink its quickly done and it works. I have two mounts, one for a bigger motor (kb45xl), all alu in L-shape, and one made of alu and carbon for a 36mm motor, which ist definately stiffer. the one for the kb killed the teeth of the center-diff due to a minimum of flex. aluminium is less stiff then eg. glassfiber, carbonfiber, and it is possible that it is still flexing a little. Connected to the chassis it also reduces the forces at the center-diff mount. its made of plastic, and it could flex like that very little as well. |

|

|

|

|

|

(#14)

|

|

|

A 16yr old with a combover

Offline

Posts: 636

Join Date: Sep 2008

Location: Mount Holly, NJ

|

01.27.2009, 01:10 PM

i thought so too, but apparently that is supposed to be a flexing chassis, and bolting the mount to it would make handling suck

|

|

|

|

(#15)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 354

Join Date: Sep 2008

Location: Hamburg, Germany

|

01.27.2009, 01:27 PM

Quote:

maybe u just try it, and when it sucks, just remove the screws. cool truggy btw! |

|

|

|

|

|

| Tags |

| cen matrix |

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

(thunder power)

(thunder power)

wings are for squares.

wings are for squares.

Hybrid Mode

Hybrid Mode