|

|

|

(#46)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

03.28.2008, 02:14 AM

Man, I am not dumb, but a picture of that would be alot easier to understand than the description.

|

|

|

|

|

|

(#47)

|

|

|

Yip Yip Yip...

Offline

Posts: 1,489

Join Date: Aug 2007

Location: Australia

|

03.28.2008, 02:14 AM

Your engine idea just made me think of a rotary nitro. Hmmm 100000rpm

. .

Mini-T Pro: Micro Pro 6800kv, Lipo, HS-81mg, Dirt Hawgs M18MT: Quark 33A, Y22S 6000kv, FP 2s Lipo LRP S8-BX: RC-M Conversion, Tekin RX8 B1600KV, 6S. |

|

|

|

(#48)

|

||

|

RC Wanna BE

Offline

Posts: 340

Join Date: Jun 2007

Location: Southern Utah

|

03.28.2008, 04:04 AM

Quote:

Emaxx Tranny slipper modification (Strobe like) http://www.rc-monster.com/forum/showthread.php?t=9341 |

|

|

|

|

|

|

(#49)

|

||

|

JERRY2KONE SUPERMAXX

Offline

Posts: 3,452

Join Date: Sep 2006

Location: HAYMARKET VIRGINIA

|

03.28.2008, 04:27 AM

Quote:

. That is a lot better then it could have been . That is a lot better then it could have been . .You will overcome and look back on this moment in time thinking what was I so worried about. Just remember the life train keeps right on moving with or without us. Don't let anything stop you from realizing your goals in life.

|

|

|

|

|

|

|

(#50)

|

|

|

RC-Monster Aluminum

Offline

Posts: 998

Join Date: Oct 2007

Location: Colorado

|

03.28.2008, 05:18 AM

No sleep for the weary (3:00 a.m.), I can't get the 30% out of my mind. I'll keep on this and I guess I need to go see a patent attourney (hate layers) and figure out what I can do.

Man you guys rock! What a good bunch of guys. I'm glad I stick around here :) I'll go ahead and get up a few pic's of the motor idea (yes it's much easier and a little more impressive when you can see it), I'd like to figure out how to make it a video so you can see how it all functions. 100,000rpm would likley grenade the materials I have to make it out of, but most fuels wouldn't burn completley at that rate. Bear in mind it has four cylinders, the equivelant of eight pistons and fires all of them twice in one revolution. I expect to get 60,000rpm out of it. You'll see soon. The RC shocks are almost done also (was taking a break from them when I found the motor pattent), so they will get posted in the next day or so (another real good application for a video), CAD is just so tedious, especially with one hand more or less. Again thanks guys. I realy do apreciate the support, realy I do. |

|

|

|

|

|

(#51)

|

||

|

RC-Monster Dual Brushless

Offline

Posts: 5,139

Join Date: Sep 2006

|

03.28.2008, 10:38 AM

Quote:

|

|

|

|

|

(#52)

|

|

|

RC-Monster Aluminum

Offline

Posts: 998

Join Date: Oct 2007

Location: Colorado

|

03.28.2008, 12:09 PM

There are some significant differences in the motor design, enough to get th pattent I think. It's just that there will be alot more time spent with the attourney $$$. If you don't have to compete with another (or multiple) pattent the process is way cheaper. I'll just have to pull some resources and mabey pick up an investor <--- less money for me :( If I do pick up a sponsor, I'm going to go with guys I'm already involved with (don't want anyone thinking I'm scamming for dollars :).

The material of choice is a ceramic hybrid (less brittle) the nasa was looking at for heat shields. Ceramic has no friction when rubbed togeather, does not expand when heated, and can do unbelievable temps without changing it's properties. You could do a motor with no rings (tollerances of 1-2 microns), no oil, and let it run as hot as the fuel burns. The heat produces by the engine (some 70% of the energy from the fuel) could be used in a secondary system (read electric hybrid) to get more efficiency. For now I think the prototype should be aluminum/steel running on two stroke fuel (thats why RC is a good place to start). I just have to work out a cooling system (to compact for air to work) and locate a prototyping shop that can do 5 axis CNC and not ask me for my first born child hahahaha. Working on pic's today (going to used some generic pic's that relay the idea without completing the full picture). Also have to finish the shock today. Anyone know about animating a cad drawing? |

|

|

|

|

|

(#53)

|

|

|

RC-Monster Aluminum

Offline

Posts: 998

Join Date: Oct 2007

Location: Colorado

|

03.28.2008, 01:01 PM

Just ordered AnimationLab for my TurboCAD program, should be here in 3 Days 92nd day air), but I'll get up a sequence of photo's in the interm so you can see a rough idea of the cycles for the motor and shock.

|

|

|

|

|

|

(#54)

|

|

|

RC-Monster Aluminum

Offline

Posts: 998

Join Date: Oct 2007

Location: Colorado

|

03.28.2008, 05:12 PM

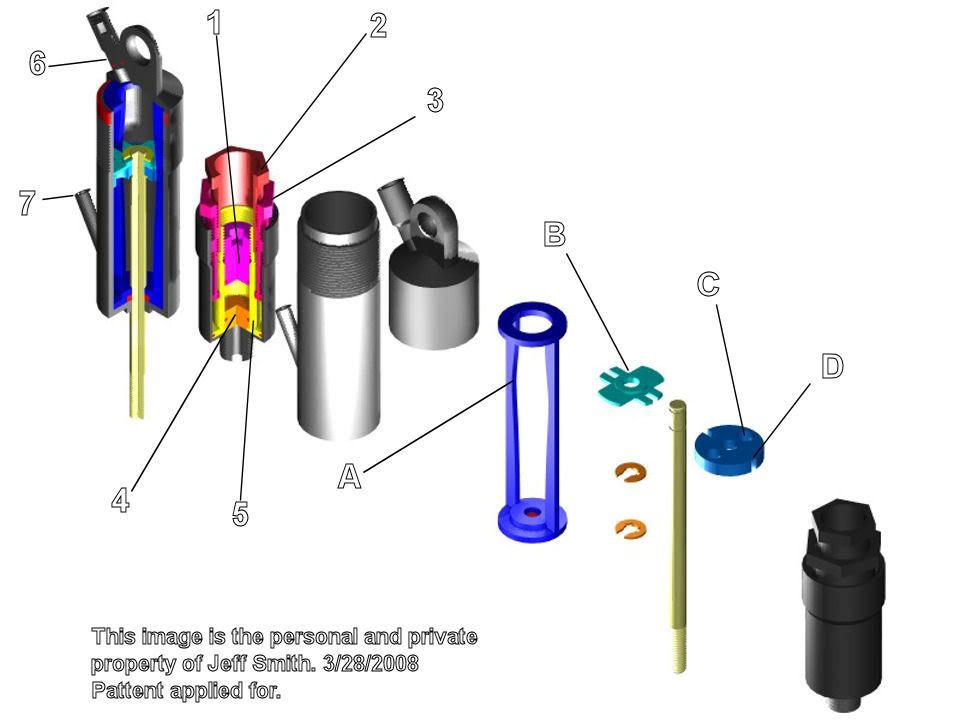

Numbers refer to parts related to the pneumatic spring system incorperated into the design. Letters refer to valving parts of the design. 1)is the adjustable high pressure apply piston, this adjusts the final portion of shock travel spring rate (top 1/3 roughly as this amount is also adjustable) its volume causes a high rate of increase for a given amount of shock travel. 2)is the piston primary travel stop. It controls how much of the shock travel is controlled by #1 versus #5. Screwing this down makes the shock harder sooner. 3)is the low pressure apply piston, this adjusts the first part of the shock travel spring rate and full extended pre load, it also is the rough adjustment for ride height. It controls roughly the bottom 2/3 of the shock travel as this is adjustable. 4) is the secondary fluid piston it has a preloaded pressure as set by #1, and moves as a unit with #5 until either the pressure on #5 is greater than the preload, or #5 comes n contact with its stop (#2). It is retained by a machined lip at the bottom of #5 and may only be removed by first removing #1 5)is the primary fluid piston and is moved by the first roughly 2/3 of the shock travel. Its volume causes a low rate of increase as to keep a maximum amount of preload for the full extension of the shock (an amount just below the pressure required for ride height, not tapering off much at full extension). 6) is a fine adjustment for ride height (changes the overall volume inside the shock body), and also serves as a bleed/ fill port (in combination with #7) so the shock fluid may be completley changed without the dissassembly of the shock assembly. 7) is the fitting for attaching a fluid line from the shock body to the air spring assembly. Valving in the next post... |

|

|

|

|

|

(#55)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,139

Join Date: Sep 2006

|

03.28.2008, 05:17 PM

That is very nice. When do you plan on making them? It would be awesome to eliminate springs.

|

|

|

|

(#56)

|

|

|

RC-Monster Aluminum

Offline

Posts: 998

Join Date: Oct 2007

Location: Colorado

|

03.28.2008, 05:43 PM

Here is where it gets a bit rough (or rougher hehehe) to follow.

A) is the valve profile, it works in unison with the slots (D) in the valve piston, to define the overall orifface size the shock oil may travel through during shock movement. Notice the profile changes from top to bottom on the inside edge. This profile is designed for easier movement around the ride height (2/3 compressed) and is more restricted at the extents of shock travel. Different profiles will be developed for different applications. It also houses the shaft seal in its bottom face to make rebuilding easier. P.S. the shaft seal will be a high end "microseal" that is lipped and able to take the 120 or so p.s.i. the shock may see... B) is the butterfly valve (carbonfiber made to flex up at the wide tabs but be rigid along the valve profile (D) grove) It sits atop the shock piston and allows fluid to bypass the valve profile through the (C) oriffaces only in downward (extension) movement. This piece can be manufactured in a number of thicknesses to dictate the pressure at which the bypass occurs. Laymen is, the tires drop faster off a jump. C) is the bypass oriffaces, these work in unison with (B) to regulate the flow during bypass. A larger orifface allows the shock to extend more rapidly, while a smaller orifface has the opposite effect. Dictated by tire weight, heavier tires= smaller orifface, to keep the car from nose diving. D) is the grove in the shock piston where the valve profile (A) goes. This works in unison with the valve profile to dictate the overall orriface size. Got it? LOL do I overthink or what?!?!?! hahaha There you have it. Adjustable spring rate (any time any where without extra springs to seperate from eachother) I'll get up some travel v.s. pressure graphs and animate them to the video of the shock/air spring motion. Slick thing here is there is good traction (pressure) on the tire even at the very end of shock travel, no coil spring can do that. The air spring is matched to shock length so they will come as a pair. You can have butter or diamonds, all adjustments are made on car without disassembly. Adjustable "position and direction" sensitive shock dampening. Way more to work with than pistons and oils. Nothing should come close to this for a while to come. I've got to do a bunch of refining for manufacture, but the idea is solid and your comment/conserns are WAY welcome. |

|

|

|

|

|

(#57)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,139

Join Date: Sep 2006

|

03.28.2008, 05:45 PM

It will be a work of art. I would love to try a set when they are done.

|

|

|

|

(#58)

|

|

|

RC-Monster Aluminum

Offline

Posts: 998

Join Date: Oct 2007

Location: Colorado

|

03.28.2008, 05:48 PM

Yah luatch, me too (note my signature). It's gonna cost a small fortune to build these in prototype from aluminum, but some of the harder bits can be plastic and some CF in production. I've got to keep the cost down if I want to sell any and have any chance of making cash on them.

|

|

|

|

|

|

(#59)

|

||

|

RC-Monster Dual Brushless

Offline

Posts: 5,139

Join Date: Sep 2006

|

03.28.2008, 06:03 PM

Quote:

. .

|

|

|

|

|

(#60)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,436

Join Date: Nov 2005

Location: Edmonds WA

|

03.28.2008, 09:44 PM

Quote:

You didnt perhaps work in the aerospace industry in Seattle for a time did you, Mr Smith? I used to work with a guy by your same name. Good luck with this development. Regarding the patent, remember, the smallest details can make a huge difference in a patent. Also, for prototyping, there are companies that offer rapid prototyping. The materials are usually a starch based plastic, some similar to epoxy resins (these are a bit more pricey). Not sure if that will apply to you, but it may be one option. I'd guess a complete shock would run you about 50 bucks to have made, 100 or so if you want to fabricat one that is slightly funtional. I am flying to Orlando in a month to the Rapid Prototyping National Conference - should be interesting.

|

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode