|

|

|

(#46)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.12.2011, 02:06 AM

I am sure 4mm front and back would be fine. I like the thicker stuff under the pinion as it gives more area for the hingepin retaining screw to thread into, and must be stronger. If you plan to use a different method to reatin the pins I see no need for the thicker stuff. And you would not have to trim the tvp if you went with the thinner material.

The stock lst upper arm is not threaded, only way to do that would be to go with the rpm lst arms and just use the end. However rpm do not make a dedicated lst2 upper arm, the use the lst1 arm they made way back when and just use some spacers to fill the void on either side. Have a look on rpms site for more info on that. I am not sure of the rpm turnbuckle size, but will bet that it is std thread, not metric. Keep an eye out, some of my cen parts arrived and I will start a new thread on that conversion tomorrow. The cvds are massive, make the shd shafts look like mini t parts. |

|

|

|

|

|

(#47)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

02.12.2011, 05:06 AM

thanks for the response linc...

I hope those turnbuckles arrive so we can finally see it all fitted with the LST parts... But quite excited by the CEN Parts now. but have no idea what to expect. I like the lst hubs as they do offer the possibility of using 3 wheel bearings, but the cen stuff must be robust anyway.... Ill be watching.. im ill, and stuck in bed so im glued the whole time |

|

|

|

|

|

(#48)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.14.2011, 11:35 PM

Ok, got the 60mm turnbuckles today.

Put them on and had a look at it. Looks good, but I overlooked one critical detail. As seen in the cen thread the st diff output cup (OC) is alot shorter than the savage. And I did all of my measurements for the pin braces with the savage OC still installed. So I will have to find a suitable OC to fit what I have, or make new pin braces. So Jahay, I am interested to see how that vorza OC fits the lst2 shaft. I will also be looking for a hot bodies lightning diff OC, as it should be a direct fit in the savvy diff. Also looking at the hellfire OC. I am guessing the hellfire OC will be the same dimension as the stock X OC. I could make some sort of sleeve to fit the X OC so that the lst2 cvd ball end fits without wobbling. I would prefer a drop in OC of the correct size. I think HB parts will be the way to go. |

|

|

|

|

|

(#49)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

02.15.2011, 06:53 AM

Ok bud...

GREAT NEWS the vorza cup is a PERFECT fit for the LST2 CVD I thought i would take some pics for you just in case...  Looks as if it would fit perfectly in this image below. OC next to it is the SHD savage cup.  The fit in the cup... There is no side ways or any movement for that matter. It is a perfect fit.  So linc, as you made your braces around the savage X cup, what does that mean? does that mean you made the braces a little too long? have you got any images of it mocked up completely and can you show the problem? i didnt think it would make much of a difference if you mocked everything up using the stock x OC or the LST OC? As i know that the vorza cups work, i am going to rebuild my vorza diffs with teh vorza OC now and make sure everything is shimmed right in the GH Bulk... hopefully no shimming is required... |

|

|

|

|

|

(#50)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

02.16.2011, 09:58 PM

Any progress? a finished product?

I am getting some plastic hubs and ordering some cvds from the states... i was going to order a whole load of new era gear, but i dont know. I want to try the plastic hubs out first. Make it work, and upgrade from there. |

|

|

|

|

|

(#51)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.17.2011, 02:06 AM

Quote:

Look at this pics of yours:  See how the slotted portion of the shd (and x) cup is longer than the vorza. My longer hingepin braces may allow the cvd bone end to pop out at max travel. I will have to pick up some cups and try it out. Business and personal life have got in the way recently. I have to take a week off from fooling with rc but will be back at it next week. I will try to order some parts this week so I have stuff in hand next week. |

|

|

|

|

|

|

(#52)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

02.17.2011, 07:13 AM

Ok i get what you are saying... so basically you have made your braces a little too wide. From what you see, can you make them so that the hinge pin sits close to the bulk without any problems???

I have rebuilt my diffs with the vorza cups now, and i have a mate sending all his hubs etc... (i just need cvds) as he got all the new era gear... if i make it work well with the plastic hubs, i may fork out and get new era hubs for my build... Give it a little more strength to deal with all the extra weight of my truck and hold the bearings well... My mate said he may be able to fit 4 bearings in the rear hub!!! But he is going to get back to me. Ill let you know how i get on! |

|

|

|

|

|

(#53)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

02.18.2011, 05:24 PM

linc... i started a little today, just mocking up and taking measurements using my Vorza diff ouputs...

I think your braces maybe a little long resulting in your cvd not sitting in the Diff output :/ From what i tested, it seems the hinge pin has to be as close to the bulk head as possible for the cvd to sit in the Diff axle as much as possible. In this pic you can see the pin in the CVD, so the cvd is sitting in the correct place.  In this pic you can see the hinge pin is compressed right up next to the bulk so the cvd fits perfectly in the diff axle.  In the pic below... the hinge pin is as close to the bulk as possible. The measured disance from centre of original Hingepin bulk head hole to the centre hinge pin sat next to the bulk is 0.6mm It would be even better if it was 0.5mm but nothing can be done about that. (BUT IM CONSIDERING THE FLM XL Arms now that are 0.5mm longer per arm as i could utilise the bulk holes?  Increased width due to lst hub over stock  Linc i am having huge problems cutting out my 4mm alloy braces! I am using a dremel and a bench grinder to shape, and they are just not doing the job! I have only completed what is below   and it took me absolutely ages just to get to this point. What tools are you using to cut it out???? Or what do people recommend for cutting things out of alloy? and neatly? |

|

|

|

|

|

(#54)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.18.2011, 05:50 PM

A fine tooth saw blade in a reciprocating saw (jig saw) works well. I use a bandsaw to cut al, and it works very well. Grinding just does not work well with al, the al gums up the stones and disks. A saw is the best method I have found.

|

|

|

|

|

|

(#55)

|

|

|

RC-Monster Aluminum

Offline

Posts: 800

Join Date: Oct 2009

|

02.18.2011, 05:55 PM

This is what I have been using to cut aluminum sheets for the small stuff, such as my battery trays for my 5T, but its also not been as thick as what I see you using.

http://www.dremel.com/en-us/Attachme...aspx?pid=EZ476 With the Ez-Lock attachment. |

|

|

|

|

|

(#57)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

02.18.2011, 06:00 PM

thanks ill look into that cutting blade... people are saying to get a bandsaw, but i think it is way too much to spend on a tool for infrequent use

the diemeter is the same as the savage... 5mm |

|

|

|

|

|

(#58)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.18.2011, 06:27 PM

Quote:

I paid about 100 bucks for my bandsaw, well spent money IMO. I cut all kinds of stuff with it. I even cut up some plumbing parts when I installed a bathtub in a tight area last year. Jig saws can be had pretty cheap. Try harbor freight, if they ship to the uk. I have seen them less than 20 bucks. I have a nice dewalt, but I paid 100 bucks for it. Good tools are a great investment. |

|

|

|

|

|

|

(#59)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

02.22.2011, 11:40 AM

linc... can you tell me what upper arm rods you bought ??? have you tried the ones you bought yet? do they work with the stock upper arms?

I am getting my new braces delivered so want to see if it all works.. just unsure which upper arm rods to buyu |

|

|

|

|

|

(#60)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.22.2011, 11:59 AM

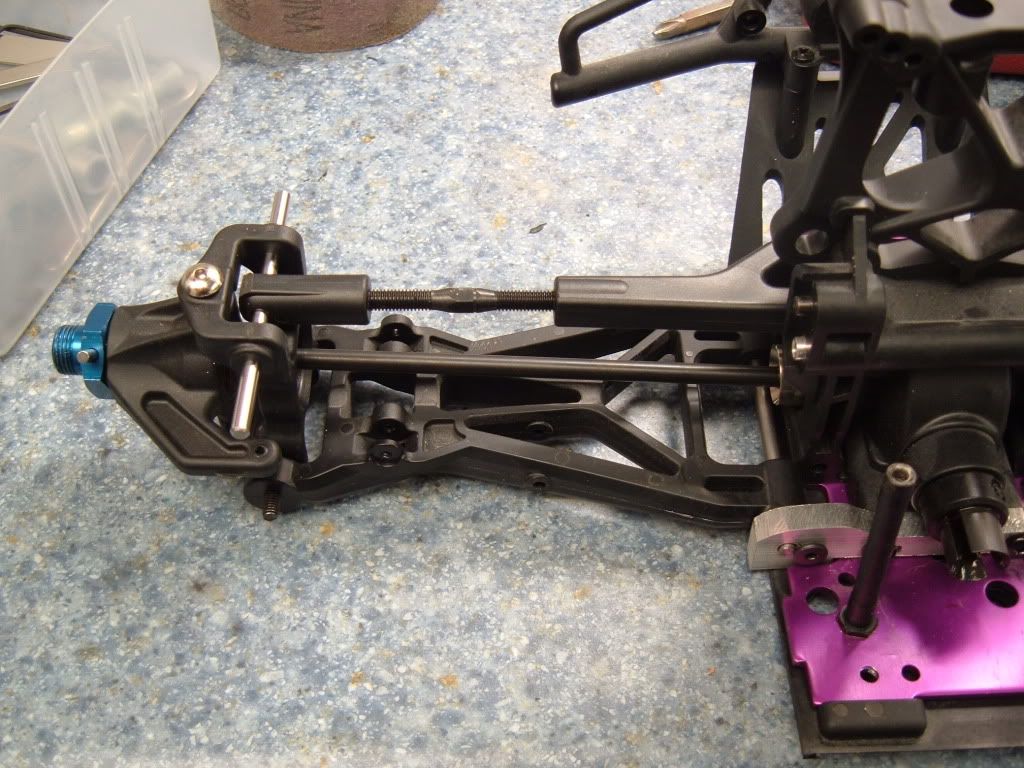

Heres a few pics. I did mod the upper arm end where it connects to the lst2 hub as mentioned earlier in the thread, and the hpi 60mm turnbuckes fit perfectly. They have enough adjustment to account for your narrower pin braces too.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode