|

|

|

|

|

(#1)

|

|

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

03.04.2010, 01:39 AM

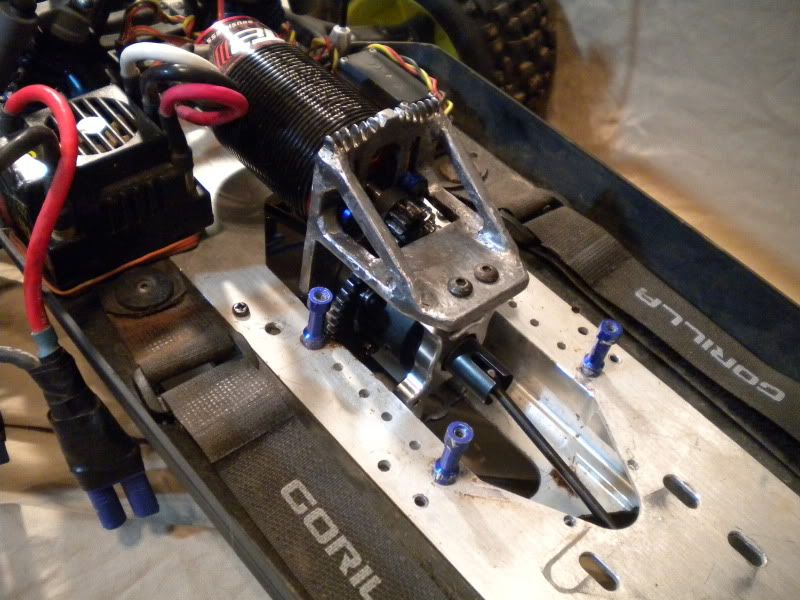

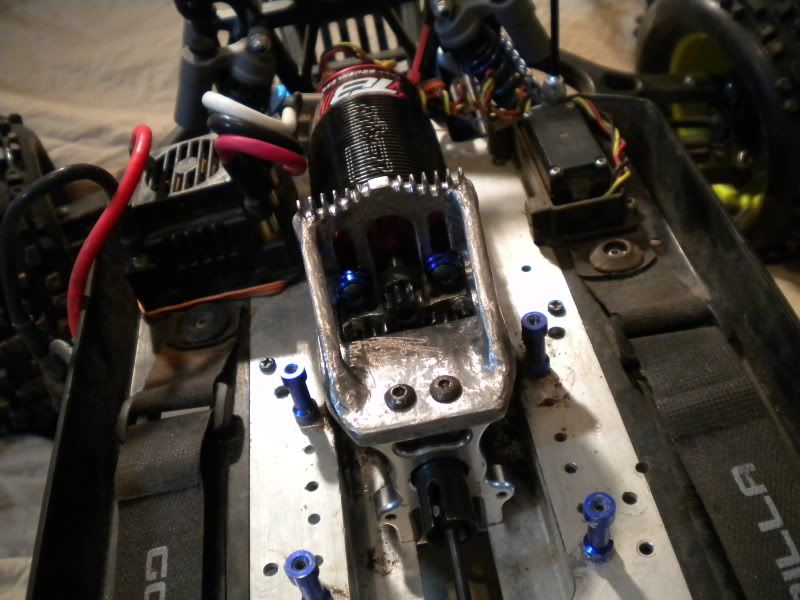

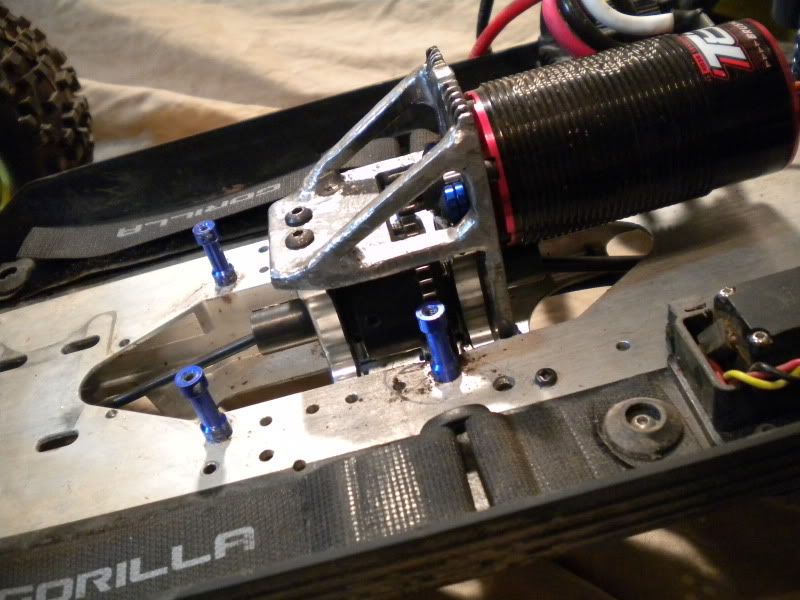

THE MOTOR MOUNT HAS BEEN INSTALLED!

Pictures of the final product (minus paint), let me know what you think of it.

Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

|

|

|

(#2)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

03.04.2010, 01:52 PM

I didnt like it at first, but now its 99% there it actually looks rather smashing

What I would do is grab some of those tiny mini hand files and give it another going over, straighten up some edges and corners etc, then polish & clear coat it; too nice to cover in paint. I think a solid one-piece version of this machined from a block of alloy ( a la UE mono-block ) would be even more awesome

|

|

|

|

|

|

(#3)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,436

Join Date: Nov 2005

Location: Edmonds WA

|

03.04.2010, 02:36 PM

I agree with Neil. How come you didn't try to make it out of AL? You can Plasma cut it, and you can MIG weld it.....

Just curious if you noticed if the holes were any harder to drill? Plasma cutting tends to harden the material - but since you then welded it afterwards, that may have reversed that process...

|

|

|

|

|

|

(#4)

|

|

|

Destroyer of Tires

Offline

Posts: 626

Join Date: Feb 2009

|

03.04.2010, 06:41 PM

I like it. Its not as "finished" of a piece like you'd get from milling it out of a solid chunk of AL. But thats part of the beauty of it, function over form and making do with what you got on hand.

It would be interesting to see this mount done in AL, both monoblock style, and welded up in a similar fashion to what you did. But if you don't have a spool gun for your MIG thats not possible. Although with a few more screws for the bracing, this mount could be made with no welding whatsoever. Either way, I like the enginuity and the final product. Especially the bracing. |

|

|

|

|

|

(#5)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,436

Join Date: Nov 2005

Location: Edmonds WA

|

03.04.2010, 11:58 PM

Actually, its quite possible. You just have to be careful to not loop your chord in too tight of a radius. I ziptied a piece of foam pipe insulation to mine to keep it "straight".

|

|

|

|

|

|

(#6)

|

|

|

roofles.

Offline

Posts: 1,982

Join Date: Oct 2008

Location: Woodland Hills, CA

|

03.04.2010, 07:03 PM

I believe he didn't use AL or anything else because he can get the hot-rolled steel quicker, and a more.....supply at once.

Don't want to give anything away incase he doesn't want me to. |

|

|

|

(#7)

|

|

|

Destroyer of Tires

Offline

Posts: 626

Join Date: Feb 2009

|

03.05.2010, 11:17 AM

Hmm, I just assumed the spool gun was for a different reason, tips, contaminating the chord, etc. While I like learning new stuff especially techniques like that, you suck, cause now I'm going to have to try it out and do projects I was putting off! Lol

|

|

|

|

|

|

(#8)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

03.05.2010, 11:57 AM

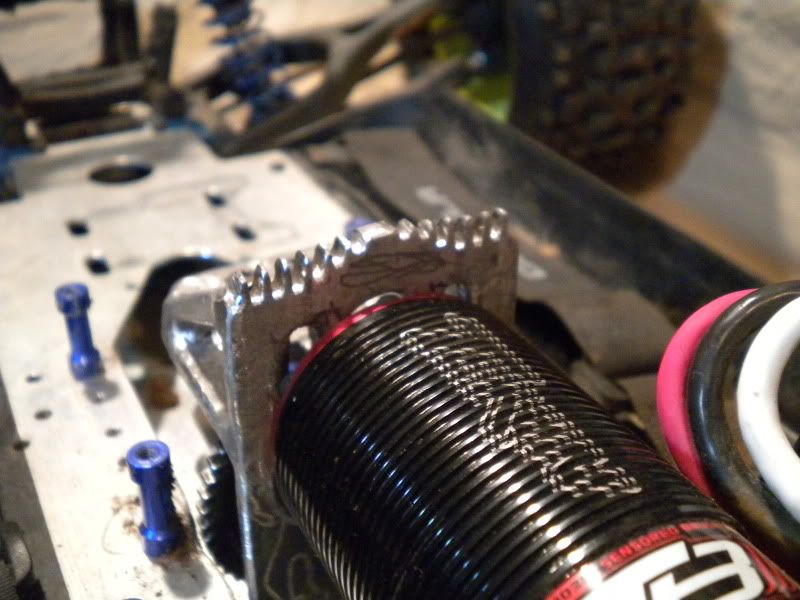

When welding material that thick with a mig (or pretty much any welding device) you will need to "V" the ends of the material where you want to weld. That way the weld penetrates the material properly. A bench grinder would do fine, just grind an angle on the piece, and weld in the V that you get when the place the ground piece against the flat piece. Looking at your welds the welder seem to be set about right for voltage, maybe lower the wire speed slightly.

Otherwise i like the result, not going to bend easily. Get good with the welds and you will not have to grind at all on them. I like a nice weld over a ground weld. |

|

|

|

|

|

(#9)

|

||||||

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

03.05.2010, 12:32 PM

Quote:

Quote:

Quote:

Thanks, means alot coming from you guys.  To Neil, not sure yet if I am going to clean it up more with files, etc. Like Overdriven said, part of the cool factor is the "not perfect but very functional" finish of it, which I kind of like. However, I may polish it to a mirror finish and clear coat it, not sure yet. To JThiessen, I didn't make it out of aluminum for a few reasons, 1 being price, not to sound like a cheapo here, but I have free access to steel at the welding shop at the community college where I take welding classes (as well as free access to the PlasmaCam CNC plasma cutter there, all of the welding machines, and all of their tools), and aluminum would have cost alot, I would have had to raise the price of the ones I wanted to sell by ALOT, and I wouldn't be able to sell any for that kind of price because RCM Mike's setup is much nicer and would probably be cheaper anyway. I do have access to a spool gun, but for the price (free to me if you don't count the cost of the welding classes), steel is just as good. Weight isn't that much of an issue in an MT anyway. Also, I didn't notice the holes being any harder to drill, but I'm sure these have some hardening, because they were dunked in cool water right after being cut out, and I did tack welds and went from 1 area to the next when welding it, so it didn't build up very much heat from welding, probably not enough to reverse any previous hardening. Quote:

Quote:

The top plate has a slight angle at the ends of the "legs" that attach to the motor plate, enough to get good weld penetration so I made sure that it did. The braces were somewhat like that, they had to be ground shorter so I put a bit more angle on them so they werent flat against the top plate and motor plate to get better weld penetration. I also tried to do a single bead and make it look nice, but I guess I am just not used to welding very small stuff yet, everything I have been doing in my welding class is 4 inch long strips (lap, t, butt, in flat, horizontal, verticle, and overhead positions), so I still need to get used to doing smaller stuff, I get all 95% grades on all of my welds for the class though, so I think I can trust my welds on this motor mount. Now if I could TIG weld, this would be a different story, I'm sure I could get a really nice bead small enough to not need grinding but still very strong if I TIG welded these. I agree though, I do prefer a nice weld bead over a ground down weld, I just haven't had the experience yet to figure out how to do a nice looking small weld bead on thicker material like this. Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

|||||

|

|

|

(#10)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

03.05.2010, 01:50 PM

Lower wire speed will help. And you will get a feel for it thru experience. I still turn out crap welds sometimes, no one is 100% all of the time!

|

|

|

|

|

|

(#11)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,436

Join Date: Nov 2005

Location: Edmonds WA

|

03.05.2010, 02:30 PM

Quote:

Krawlin - have you done much torch welding? I'm kinda curious now if you could do the same assembly using some .125 or thinner steel plate and torch weld it together. That would leave a very nice finish, and I'd think it would be just as strong. good point on your choice of steel. I'm just the opposite here - I have an unlimited supply of Aluminum, but very little steel (tends to make the big birds too heavy!!).

|

|

|

|

|

|

|

(#12)

|

||

|

Destroyer of Tires

Offline

Posts: 626

Join Date: Feb 2009

|

03.05.2010, 09:58 PM

Quote:

Tanks are cheap for me. I use old 20lb CO2 fire extinguisher tanks from work. I just hydrotest it after hours, and I only have to pay for the valve and fill. And paint the argon a different color so I don't mix them up! |

|

|

|

|

|

|

(#13)

|

|

|

RC-Monster Square Tube

Offline

Posts: 1,367

Join Date: Jun 2008

Location: CNY

|

03.05.2010, 08:11 PM

Not bad krawlin, with .023" wire MIG you could get some smaller beads, with just using a small circular motion. Lots of welders will only do that with stick welding, but it's almost always beneficial regardless the process you're using.

With a newer squarewave TIG it's possible to use a 2% Thoriated tungsten ground to a point with AC, which is what you need for some gorgeous aluminum beads. MIG is a great place to start, but once you've done some stainless with a TIG, nothing else compares. Looks pretty good, keep it up. My Videos: http://vimeo.com/user2236105/videos |

|

|

|

|

|

(#14)

|

|||

|

Got brushless?

Offline

Posts: 592

Join Date: Aug 2008

Location: Sierra Vista, Arizona

|

03.06.2010, 12:16 AM

Quote:

Quote:

And actually I am currently using .035'' wire in MIG, didn't think to change it out for thinner wire, but then again I have no idea what wire sizes they have in the welding shop here, probably thinner stuff but I didn't think to look. And I was taught to do the circular motion with MIG to get the nice bead and proper penetration, etc., but like I said before, when I tried it with these motor mounts, I ended up with a big fat glob, so I did a whole bunch of tack welds and very short welds in some places. Like Linc was saying though, probably lowering my settings would have helped, although to really end up with a good small bead I would have had to drop down to smaller wire like you were saying. Proud Member & Online Recruiter for Team Terribles! Mugen MBX5-T - Rc-bearings.com

|

||

|

|

|

(#15)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,436

Join Date: Nov 2005

Location: Edmonds WA

|

03.06.2010, 12:47 AM

Geez.....Friday night, the wife is out of town, and here i am looking at pictures of your stinking welds.....

Christ I'm old.... Christ I'm old....How did the cuts look on your welds? (I assume they cut through the welds to check porosity and depth>) Is stick welding still taught? Horizontal overheads killed me - aced all the vertical welding - had a knack for the weave, I guess.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode