|

|

|

(#76)

|

|

|

RC-Monster Brushless

Offline

Posts: 3,156

Join Date: Jul 2005

Location: Gramercy, LA

|

06.03.2010, 04:03 PM

Romano- what battery box are you using?

I'm looking at the steering servo right now. I have a ACE 1015 which is both strong and fast and will be plenty in a GTP. Most people end up dialing out dual rate and EPA for high speed running. Is this steering servo really necessary? or should I look into a different one? |

|

|

|

(#77)

|

|

|

Fat Kid Engineering

Offline

Posts: 3,634

Join Date: Jun 2009

Location: Hot as Hell West Central Coast Florida

|

06.03.2010, 04:25 PM

Thanks again for the pics Snell, the offset is nothing that can't be worked with I dont think. Your efforts are appreciated Sir !

NitroSniffer, I think anything is going to be overkill for straight line duty. I have a NIP JR-650 I'm gonna throw in mine, decent strenth and reliability is my bigger concerns than speed. |

|

|

|

|

|

(#78)

|

|

|

2 KiloWatt RACER

Offline

Posts: 2,496

Join Date: May 2007

Location: Houston

|

06.03.2010, 04:29 PM

My buddy uses a fast servo, but I just use a plain 'ol slow digital metal gear one. I forgot what model number. I can check later.

Nitro, that is not a battery box...it's one of those plastic tool drawer things. Tall and wide enough for my cube A123's. GTP-Pletty Big Maxximum+RX8. GTP-C50-6L Hacker+RX8. CRT.5-Pro4+ZTW esc. 24s2p EVG SX 49.6mph Ebike. 18s4p Raptor 60mph Ebike. 11.5KW |

|

|

|

|

|

(#79)

|

||

|

RC-Monster Brushless

Offline

Posts: 3,156

Join Date: Jul 2005

Location: Gramercy, LA

|

06.03.2010, 04:31 PM

Quote:

I hear ya Bondoballz. That pretty much what I was thinking. Just thought I would get a few opinions on the subject. |

|

|

|

|

(#80)

|

|

|

RC-Monster Brushless

Offline

Posts: 3,156

Join Date: Jul 2005

Location: Gramercy, LA

|

06.04.2010, 10:09 AM

Whats the word on ride height? I know the downforce will compress the suspension a bit, but how much? Is this able to be calculated?

|

|

|

|

(#81)

|

|

|

Fat Kid Engineering

Offline

Posts: 3,634

Join Date: Jun 2009

Location: Hot as Hell West Central Coast Florida

|

06.04.2010, 10:28 AM

Great insight and question, I never would have thunk it.

Curious to hear an answer on this myself ? |

|

|

|

|

|

(#82)

|

||

|

RC-Monster Brushless

Offline

Posts: 3,156

Join Date: Jul 2005

Location: Gramercy, LA

|

06.04.2010, 10:33 AM

Quote:

I understand you want to set up the car low, but how low? Too low and a good body would cause the suspension to bottom out going down the straight?

|

|

|

|

|

(#83)

|

|

|

Destroyer of Tires

Offline

Posts: 626

Join Date: Feb 2009

|

06.04.2010, 10:46 AM

Funny thing about Indy + F1 cars, if you need more traction in a corner, go faster. While more speed = more downforce is easily understood, try telling your brain to press on the gas more in that situation!

I'm sure there are formulas Indy + F1 teams use, but they know how much downforce the car makes, spring rates, etc. Doubt anyone knows exactly how much a particular rc body makes. I'm sure someone will pipe in with a useful setup though. I wonder if you could use something attached to the chassis to see how much the suspension compresses during a run. My first thought is clay, that would wear if it touched pavement, but I'm sure someone could come up with something better. |

|

|

|

|

|

(#84)

|

|

|

2 KiloWatt RACER

Offline

Posts: 2,496

Join Date: May 2007

Location: Houston

|

06.04.2010, 11:05 AM

I setup my chassis so that it levels out evenly under acceleration. I prefer my driveline to be parallel with the ground as well. But this is just how I run. Setup might need adjustment once I use a different body.

GTP-Pletty Big Maxximum+RX8. GTP-C50-6L Hacker+RX8. CRT.5-Pro4+ZTW esc. 24s2p EVG SX 49.6mph Ebike. 18s4p Raptor 60mph Ebike. 11.5KW |

|

|

|

|

|

(#85)

|

||

|

RC-Monster Brushless

Offline

Posts: 3,156

Join Date: Jul 2005

Location: Gramercy, LA

|

06.04.2010, 11:25 AM

Quote:

I was thinking along the line. Something attached to the chassis that would monitor the suspension arms movements. However, the condition of the ground would impair this measurement as the suspension moves on every dip and raise. I guess my question is how do you tell chassis position under acceleration beside eyeballing it? |

|

|

|

|

(#86)

|

|

|

Destroyer of Tires

Offline

Posts: 626

Join Date: Feb 2009

|

06.04.2010, 11:37 AM

You could do the same thing with one of those mini-cams. I probably wasn't thinking about it because I like most guys don't have one. But it could watch the suspension arms while under the body easy enough. If you want to get scientific, place a ruler (or something else with graduations on it for reference) by the arm you're filming to get a more accurate reading of it's position.

|

|

|

|

|

|

(#87)

|

|

|

2 KiloWatt RACER

Offline

Posts: 2,496

Join Date: May 2007

Location: Houston

|

06.04.2010, 11:56 AM

I'm old school and I use eyeballs for my setups. Too much calculating takes away from play time. I use trial and error and have fun doing it. I setup for lets say 60mph and see how the car behaves. I change gearing for a higher speed and see how the car behaves. Calculations will only bring you so far. The only calculations I do, is with the use my simple spreadsheet. And back those numbers up with my datalogger. Kinda works like BrianG calculator. You don't have a wind tunnel to play with, so why waste time calculating things you don't have hard numbers for.

70mph in a 1/8 is pretty damn fast and still affordable to me. 100mph is just stupid fast and I can't afford the upkeep of such a monster without my wife killing me. GTP-Pletty Big Maxximum+RX8. GTP-C50-6L Hacker+RX8. CRT.5-Pro4+ZTW esc. 24s2p EVG SX 49.6mph Ebike. 18s4p Raptor 60mph Ebike. 11.5KW |

|

|

|

|

|

(#88)

|

||

|

RC-Monster Brushless

Offline

Posts: 3,156

Join Date: Jul 2005

Location: Gramercy, LA

|

06.04.2010, 12:36 PM

Quote:

100mph is just cool!  Over 100mph is, well its Over 100mph is, well its  I want to go 112.15mph which is .01 over my LHS guy's GTP. |

|

|

|

|

(#89)

|

|

|

2 KiloWatt RACER

Offline

Posts: 2,496

Join Date: May 2007

Location: Houston

|

06.04.2010, 01:03 PM

Closest I've been, must of been in the lower 90's. Too bad I erased the datalog file by accident of that one and only run. I probably could go faster with better batteries and tires. Probably also getting rid of all the dogbones would help as well. OR or or is it maybe the limitation of my RX8 over the MMM esc.

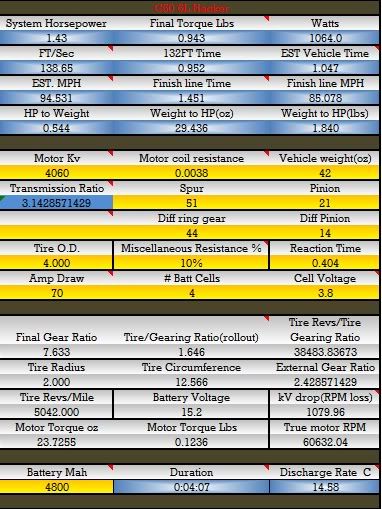

This is as far as I go when it comes to calculations. Snippet of my spreadsheet. I have one of those for every motor that I have. Vehicle weight is off in this spreadsheet.

GTP-Pletty Big Maxximum+RX8. GTP-C50-6L Hacker+RX8. CRT.5-Pro4+ZTW esc. 24s2p EVG SX 49.6mph Ebike. 18s4p Raptor 60mph Ebike. 11.5KW |

|

|

|

|

|

(#90)

|

|

|

RC-Unobtainium

Offline

Posts: 1,032

Join Date: Jul 2008

Location: Sydney

|

06.04.2010, 05:56 PM

I'll have a crack at a few considerations;

- in my experience the servo can be anything because steering weight isn't an issue for straight line running. If however you install a gyro, speed becomes an issue...it needs to keep up with gyro. I have a couple of those 1015's - fast, strong & they work nicely with a gyro the way I've used them - again in my experience fore and aft downforce/suspension can be measured by feel & eyeball. Too soft in the rear & you loose steering when you're accelerating hard...too soft in the front & you'll loose the back end when braking (the back will try & overtake the front). Kind of basic as a theory but it's worked for me - ride height depends on the running surface. A 1/10 TC has < 1/4" at speed but hit a bump in the road & it's airborne...I would think somewhere between 1/2-3/4" for 1/8 scale is a reasonable starting point. Here's my Rustler...has about 1/2" in the static position. I limited the shock upstroke with fuel tube (pink) so that it never bottomed out but there's no evidence that the shock ever compressed that far...I had it up over 95mph by my GPS  - I would use the stiffest springs available & 50-70wt shock oil, depending on the brand (I use 70wt Losi in my 8T) & then fine tune ride height etc on the shock itself I look at speed runs as an equation. If the equation is balanced then controllable speed will come relatively easily Losi 8ight-T |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode