Quote:

|

Originally Posted by jhautz

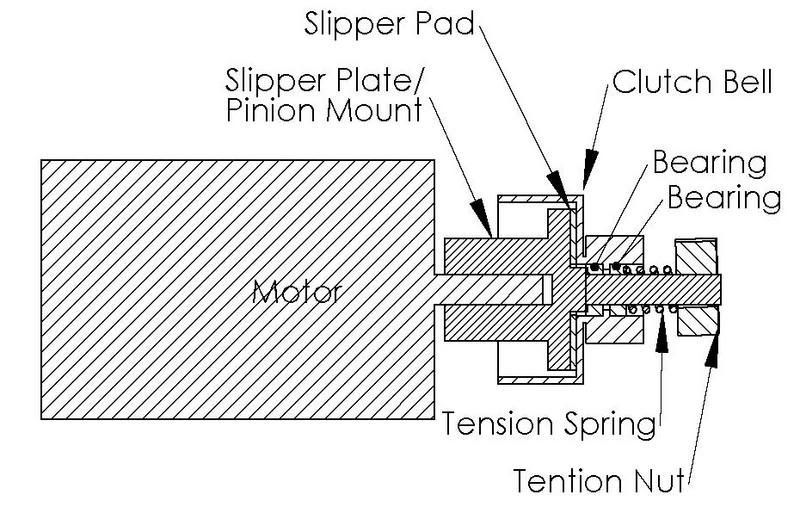

What about moving the slipper pad to the flat inner face of the clutch bell and using a conventional spring and nut to adjust slipper tention.

Something like this.

|

That looks good, but would there be too much stress on the bearings essentially shearing them apart (the CB pushing out while the hub is being pushed in)?

BTW: I'm glad there are others tying to think of a way to do something like this! It doesn't even have to use a CB; I just decided to try it since I had one on hand for measurements.