|

|

|

(#16)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

10.26.2006, 12:28 AM

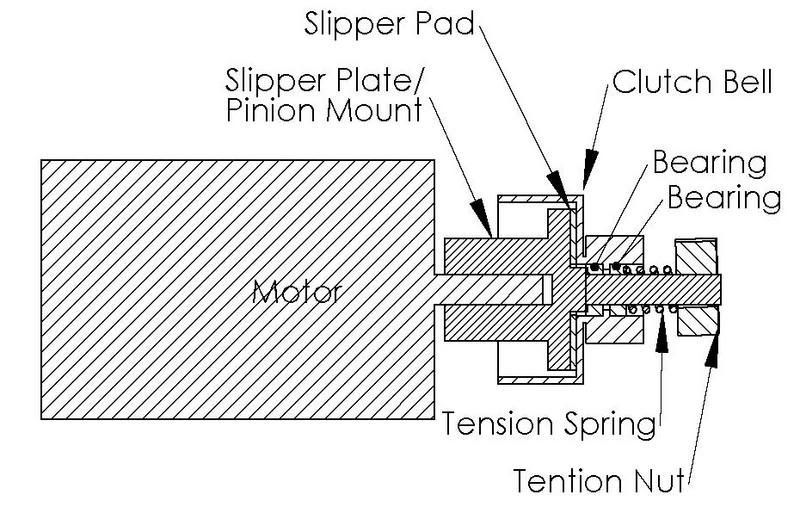

For the tension, there are spring-loaded screws, probably four in all. The springs are the red dots - remember, it's a cut-away view. The problem with this is you have to have the CB seperate from the hub to adjust the tension, then have to muscle it back in the CB. Then again, you generally don't want too much slip since it's really intended for drivetrain protection so there shouldn't be much adjustment. The screw part could be eliminated, but then there would be nothing to stop the pads from gripping harder at high rpm due to centrifugal force (same problem as with using clutch shoes, mentioned earlier). The springs provide the force, the screws provide the limit.

It's hard to make stuff in Excel (but much faster) so it might not be readily apparent. This version looks much easier and cheaper to build. |

|

|

|

(#17)

|

||

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

10.26.2006, 12:32 AM

Quote:

BTW: I'm glad there are others tying to think of a way to do something like this! It doesn't even have to use a CB; I just decided to try it since I had one on hand for measurements. |

|

|

|

|

(#18)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

10.26.2006, 12:35 AM

You could make little spacers that would stack up and contact only on the inner ring of the bearing. Esentially makeing a solid column to support the load. Than the balls in the bearing would not take the load.

This was just a rough concept sketch. There would be plenty of details to work out. I think that something like this could work though. to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#19)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

10.26.2006, 12:45 AM

Well, if the bearing load thing can be worked out, this could very well work. Like I said; we don't need a clutch, we need protection for the drivetrain - something has to give. So, as long as the slipper will give only at a certain amount of resistance, it'll be golden.

Another CRAZY idea I was thinking about: magnetic slipper. I have a couple magnets I pulled out of a dead harddrive and they are CRAZY STRONG! They can support their weight (with a metal plate attached to them) throught the thickness of my hand. So, put a series of small magnets really close to each other (~0.5mm) in something like a clutch bell. I'm thinking it will be essentially locked unless some kind of outside force breaks them loose. And best of all, no heat when they do slip. Again, I'm just thinking out loud here... |

|

|

|

(#20)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

10.26.2006, 01:12 AM

Id be a little concerned about putting magnets that powerful that close to the magnets in the motor. Who knows... Maybe they would cancel each other out and you would loose power in the motor.:005:

Seriously though. I think that magnets would weigh an awful lot. Remember, adding weight to the pinion has a MUCH larger effect on the total rotational mass than adding weight on say the wheels. A crazy Idea I had was wanting to design a slipper clutch that worked like the keyless chuck on a power drill (but smaller obviously). Having numbers around the outside and you just hold the spur and rotated the slipper to dial in your desired tention. That way when you found the tention that worked, you could always go right back to it without guessing. BTW: So when are you going to start working on the prototype of this slipper idea???:p to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#21)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

10.26.2006, 01:17 AM

Just thought of another thing to worry about with any of these slipper designs. The heat generated by a slipper would be being transfered to the motor shaft and into the motor. I'm not sure if its enough to worry about, but the motors generate enough heat already. We don't need to be adding more.

to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#22)

|

||

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

10.26.2006, 01:26 AM

Quote:

|

|

|

|

|

(#23)

|

|

|

RC-Monster Aluminum

Offline

Posts: 517

Join Date: Jul 2006

Location: Utah

|

10.26.2006, 03:49 PM

I really like this idea as it would eliminate our troubles with pinions and gearing since we could use standard clutch bells. My only concern from heat would be fade from limited contact area. With a center diff you don't really need much slipping action, so that wouldn't be an issue, but on the monster trucks where some slipping would be beneficial aside from just protection I would worry about heat generation.

|

|

|

|

|

|

(#24)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

10.26.2006, 05:08 PM

This thread talks about the hardened steel pinions and Mike's view on them. I'm thinking that a slipper would go a long way to make those pinions wear better since there would be some give with some form of slipper.

I'm not sure about the potential heat issue. Nitros use the clutch a lot harder since it slips most at low rpm. The heat is caused by the rubbing surfaces when there is slippage. As long as the hub and CB spin at the same rate, there is no slipping, therefore no heat. I wonder what Mike's take is on all this? I'd be curious as to what he thinks. |

|

|

|

(#25)

|

||

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

10.26.2006, 05:15 PM

Quote:

The drill chuck idea may be an alternative. I have no idea how that works though since it seems to rely on some type of ratcheting resistance. Making as small as it would need to be to fit in the sapce allocated may compromise its strength. Keep the ideas coming. :) |

|

|

|

|

(#26)

|

||

|

RC-Monster Aluminum

Offline

Posts: 517

Join Date: Jul 2006

Location: Utah

|

10.26.2006, 09:22 PM

Quote:

I still don't think any effective drive gear solutions exist as abundantly (and therefore inexpensively) as clutch bells. |

|

|

|

|

|

|

(#27)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

10.26.2006, 09:54 PM

Don't forget; my drawings are crude cut-aways. I was thinking of having four seperate fairly large pads covering the majority of the CB depth, which should approximate the amount of suface area of clutch shoes.

Yeah, there really isn't anything for buggy conversions yet, hence this thread. |

|

|

|

(#28)

|

|

|

Guest

Posts: n/a

|

01.15.2007, 01:30 PM

I know this is an old thread but all you slipperential needers need not worry. A drop in slipperential solution for all center-diff equipped truggy/buggy's is near. Stay tuned.

And if you have a CRT conversion , you're gonna love it even more. |

|

|

|

|

|

(#29)

|

|

|

Guest

Posts: n/a

|

01.15.2007, 02:40 PM

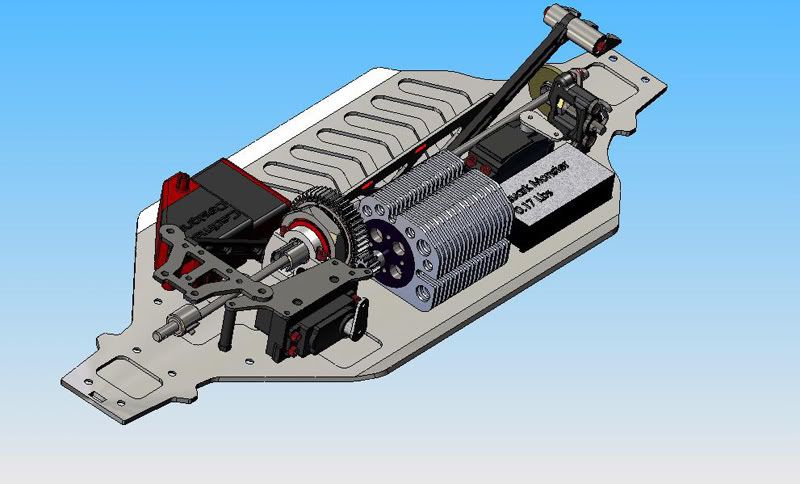

Here's a peak at my Jammin CRT conversion I am working on. Look close and you can see the next-gen slipperential Mike and I are working on.

|

|

|

|

|

|

(#30)

|

|

|

Hyper 7 Erevo Center Diff

Offline

Posts: 1,195

Join Date: Dec 2005

Location: CNY (Syracuse/Binghampton area)

|

01.15.2007, 02:49 PM

that would be the slipper-diff wouldn't it.....mike explained it to me on the phone once....I can't wait to see this.... by the way nice renders....

Quark 125b Castle Creations-Neu 2200kv motor ((2s2p)(4s)7800mah 7.4v Lipo Pack E-Revo 1/8 scale Hyper 7 CD http://www.rc-monster.com/forum/show...1&goto=newpost |

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode