|

center diff conversion |

|

|

(#1)

|

|

|

Guest

Posts: n/a

|

center diff conversion -

05.20.2005, 08:40 PM

what ever happened 2 this idea thinking about getting a new chassis and i really liked that idea and im trying 2 decide between a bpp chassis and a gmaxx

|

|

|

|

|

|

(#3)

|

|

|

Site Owner

Offline

Posts: 4,915

Join Date: Nov 2004

Location: PA

|

05.21.2005, 10:18 AM

The idea is still there, although I haven't really had the time to devote to the project, as I have been busy with other projects(building trucks, pinions, idler gears, etc.). It wouldn't be too hard to mount a center diff(several folks have done it), although I wanted to incorporate a slipper clutch as well. I still will do something with this, but I am not sure when.

|

|

|

|

|

|

(#4)

|

|

|

RC-Monster Mod

Offline

Posts: 2,487

Join Date: Feb 2005

|

05.23.2005, 01:49 AM

I have a nice milled center diff mount with integrated motor mount for a BL Revo lying around on my workbench .....er, I mean in my dreams :p

|

|

|

|

|

|

(#5)

|

|

|

RC-Monster Admin

Offline

Posts: 10,480

Join Date: Feb 2005

|

05.23.2005, 12:18 PM

I am going to build one for my maxx rather soon, and perhaps one for my savage too (initially planned on using it in my savage...)

The only electric car i know that uses both is the 1/16th byggy (don't know the brand anymore.. was it kyosho?) |

|

|

|

|

|

(#6)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

05.23.2005, 08:51 PM

For a while I had been working on a custom monster truck project using Maxx diffs. I was working with a custom center transmission consisting of just a shaft with an integrated slipper clutch/spur gear mount. The problem I ran into is that I wouldn't have been able to gear properly because of the relatively low gear ratio of the Maxx diffs (2.846:1). I did make a special gear/motor mount that utilized a total of 4 gears (including motor pinion gear) that had a built in Revo slipper clutch. This made it possible to get the perfect ratio without using gigantic spur gears and microscopic pinions.

The reason why many buggies [and truggies] can use a center diff is because the F/R diffs have a ratio somewhere around 3.25 (3.14 for Ofnas). Since getting a 1/8 buggy, I have found that I can mod it so that there isn't a center diff, but a shaft with a spur gear mount that lets me use up to a 64t 32p spur. When put with a small pinion, this would be very ideal. Now I just need to get a slipper clutch onto this! |

|

|

|

|

|

(#7)

|

|

|

Site Owner

Offline

Posts: 4,915

Join Date: Nov 2004

Location: PA

|

05.23.2005, 09:11 PM

Interesting. I Have given some thought to mounting a wide toothed 32 pitch gear onto a center diff to allow greater reduction. As long as the teeth on the 32 pitch gear is wide enough (along with wide teeth on the pinion), the gear should hold up pretty well. I like the benefits of a center diff vs. direct drive with a slipper, especially for longer wheelbases.

|

|

|

|

|

|

(#8)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

05.23.2005, 09:37 PM

I too like the use of a center diff, but the one that came with the buggy (used) seemed to be leaking diff oil and only had a 46t steel spur with no possiblity of a plastic gear. I have been thinking about getting an Ofna diff from a MBX or something similar with a 52t mod1 spur, but what I have now is working pretty well.

|

|

|

|

|

|

(#9)

|

|

|

Site Owner

Offline

Posts: 4,915

Join Date: Nov 2004

Location: PA

|

05.23.2005, 09:40 PM

I picked up the parts a month or so ago to build a few of these diffs. The ofna 51 tooth delrin spur mounts directly to it. I also have a few delrin mod1 gears that I may try to modify (42 tooth will fit between the chassis braces on a maxx). It just takes time, and I have been pretty busy with a few other projects, so I haven't had the time to mess with it. The ideas are all in my head, though!!

|

|

|

|

|

|

(#10)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

05.23.2005, 09:48 PM

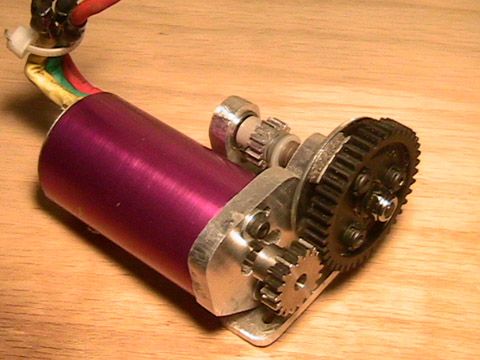

Just for reference, I have some pics of the "gear reduction unit" that I made:

The drawback for this is rotating mass, more general weight, and more friction. I think it might be a good alternative to an E-Maxx transmission, without the 2-speed. |

|

|

|

|

|

(#11)

|

|

|

Site Owner

Offline

Posts: 4,915

Join Date: Nov 2004

Location: PA

|

05.23.2005, 10:05 PM

Interesting unit! It si basicaly like a single speed e-maxx tranny laid on its side. I guess you would have to mount the batteries opposite the motor?

|

|

|

|

|

|

(#12)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

05.23.2005, 10:41 PM

That was the idea. That chassis that it is mounted on was just an old one. I made a newer chassis since then, but this project was discontinued due to the difficulty of getting it together. Really all I needed were specialized bulkheads that could mount the arms that I specially designed. Even though the project died, I still have ideas from it, and they may come in handy later on.

|

|

|

|

|

|

(#13)

|

|

|

RC-Monster Admin

Offline

Posts: 10,480

Join Date: Feb 2005

|

05.24.2005, 02:02 AM

Mike;

A 44 tooth gear also fits perfectly between the gmaxx frame. (i also was working on something like this, to keep a low cg) And if you use the FLM 1/8th bulkless you could use the HB lighting diffs, 43/10. |

|

|

|

|

|

(#14)

|

|

|

RC-Monster Mod

Offline

Posts: 2,487

Join Date: Feb 2005

|

05.24.2005, 03:06 AM

Metal Man, your thing looks well made. I, too, ran into the same calculations.

In my customized Revo I would have lots of space for a huge spur. I always think of a very big gear attached to a center diff (with or without slipper) right in the middle of the truck. I could make room for the big spur and reinforce the chassis next to it (if it's not strong enough anyway). The real challenge would then be the diff brace, which should include a motor mount. If only I would have access to some proper tools or have a contact to a cool machinist .... I also have put the center diff project to a rest, the g-maxx tranny made me change my mind, but I will come back to this later on. Maybe I'll have the possibility to work together with someone, one fine day. |

|

|

|

|

|

(#15)

|

|

|

RC-Monster Admin

Offline

Posts: 10,480

Join Date: Feb 2005

|

06.14.2005, 10:12 AM

Metalman; That is a revo slipper your using, right?

i found out a nice way to make a-cad like drawings (thanks Mike)I will drop a few screenshots if i have got it finished |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode