|

|

|

(#46)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

06.16.2015, 01:08 PM

I just looked into my old mails, the last treaded ones I bought were from November 2014, not early 2015 as I first thought. If it is really true that the 2015 tyres all have the same compound then I guess I can ditch my Slash after I've gone through the last set I have from 2014 :(

|

|

|

|

|

|

(#47)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 133

Join Date: Oct 2014

Location: Germany

|

06.16.2015, 01:16 PM

Can't imagine we're the only ones being disappointed with the new compound, maybe they'll change it back next season. I did see something about ROAR and US market though, hope that was just about the wheels and not the compounds (don't what part would actually be regulated). In the meantime, maybe S1 comes close.

|

|

|

|

|

|

(#48)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

06.19.2015, 10:48 AM

Dr.T: There was also somebody on the Traxxas forum who noticed the same with the slicks.

Finally, I received a package from Alienpower. But somehow, the ESC is not repaired like Bruno told me before. Also, the motor was not touched although he told me he would replace a broken sensor. Instead, there is a new ESC in the package. But an un-sensored one. And the Program Box (that wasn't delivered when I bought the set) is still missing but there is another USB Adapter. Definitely not recommended.  And my VESC has been repaired. The FET Driver has been replaced, now it's working again. Benjamin already did a no-load test with my 1717, runs well according to him. He also wanted to do more tests under load, very cool. Why the driver failed is unclear, Benjamin said it could have been a short somewhere. Well, I'm pretty sure there was no short, but who knows, maybe I sprinkled some solder somehwere and didn't notice. Next time I'll definitely make sure that there are no shorts. Here is a video of the repair :) [youtube]O7vaW27kdLo[/youtube] |

|

|

|

|

|

(#49)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 133

Join Date: Oct 2014

Location: Germany

|

06.19.2015, 12:21 PM

Crap of your bad experience with APS... What are gonna do? Get sensors off and try what it does sensorless? The extra poles should make it slightly smoother than a 4-pole under same roll-out.

I guess the more people complain, the more likely it is they'll make some changes again for next year. I think they update their compound almost yearly anyway, no? |

|

|

|

|

|

(#50)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

06.19.2015, 12:41 PM

Not sure yet. Maybe I'll just put it in the XO-1 and sell it. Now that my twin runs, I think I won't drive it very often anymore, it's annoying to find a perfect road. Then I could put the Trackstar (that didn't seem to like the Turnigy 5682, cogging like crazy) in the Savage, maybe it will work better with the 1515 in the Savage.

Yeah, I think they update it every year or almost every year. I'll write them a mail too :) |

|

|

|

|

|

(#51)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

08.15.2015, 06:33 AM

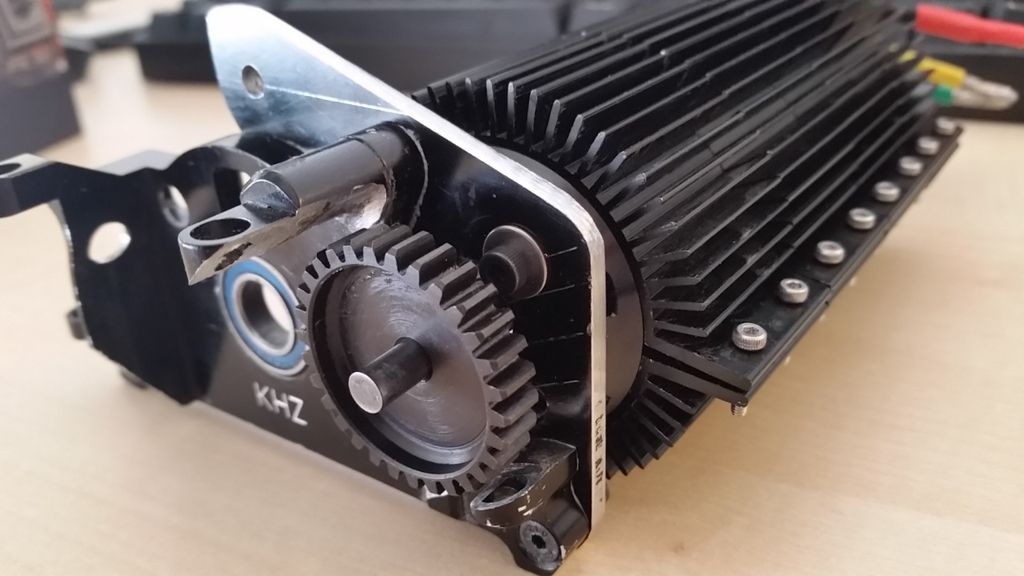

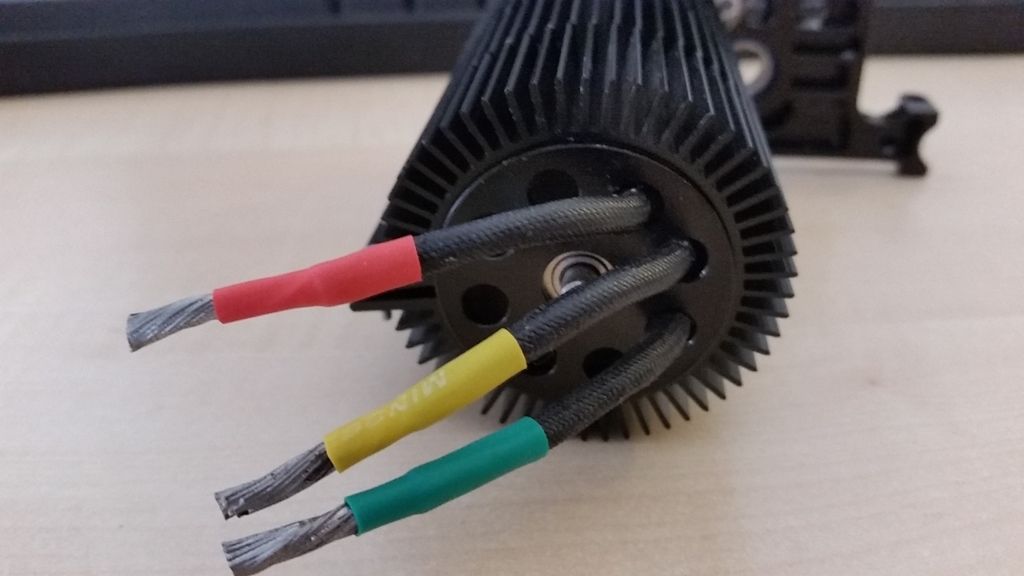

Put a TPPower 4070 3Y 1440kv in the Slash. Heatsinks are from Dr. Mad Thrust Hobbyking. 30t pinion and 36t spur should give 184kph (114mph) theoretically calculated with 3.7V per cell and (measured) 1550kv.

Tried it out today and reached 172kph (107mph) :D [youtube]QtvF6btCq0c[/youtube] Motor ran great, but not too long :( During the first battery, suddenly the motor spooled up but the car wouldn't move. First thought broken slipper or loose pinion, but after looking more thoroughly, it's weird: The rotor can be turned with almost no resistance, there is no magnet drag at all (before, magnet drag was very strong) and there are grinding sounds. I don't think it's de-magnetized, checked motor temps ofen, never got higher than 52 celsius. Since the motor spooled up, but the pinion wouldn't spin, I think the only explanation is, that the rotor somehow came loose from the shaft?

|

|

|

|

|

|

(#52)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

08.15.2015, 01:02 PM

My rotor came loose from the shaft once. I used the hard core permanent locktight and it worked. I think the color was green

|

|

|

|

|

|

(#53)

|

||

|

working on a brushless for my wheelchair.....

Offline

Posts: 4,890

Join Date: Mar 2007

Location: minnesnowta

|

08.15.2015, 01:15 PM

Quote:

It's "Dr. _paralyzed_" actually. Not like with a PhD, but Doctor like in Dr. Pepper. |

|

|

|

|

|

|

(#54)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 133

Join Date: Oct 2014

Location: Germany

|

08.15.2015, 01:58 PM

Nice speed! Crap to hear about the rotor detaching... You got it directly from TP Europe? Let us know how they deal with your warranty claim please.

Can you tell if the 5 mm shaft is a turned down 8 mm, or 5 mm all the way through? Back looks 5 mm too, right? I'm thinking of getting another one soon too, but not sure wheter to get the 5 or 8 mm... Those heatsinks fit nicely! I might have to steal that idea from you :). |

|

|

|

|

|

(#55)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

08.16.2015, 04:04 AM

Yeah, I've already mailed TPPower Europe, they answered they will forward my mail to one of their engineers.

The shaft seems to be 5mm all the way through (assuming it's not bigger diameter behind the bearings which probably wouldn't make sense). Not sure if that is good, atleast some Leopard 4092's had problems with vibrating shafts when spinning over 25k rpm or something. But I think I remember somebody on URC saying that the 5mm versions actually have 8mm shafts, but turned down to 5mm. Maybe they changed something again with their motors? Man this is so annoying with those TPPower guys, you never know what you will get, probably they have no clue themselves what comes out of their factory ... |

|

|

|

|

|

(#56)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 235

Join Date: Nov 2012

Location: The Netherlands.

|

08.16.2015, 04:02 PM

It is a total different motor, but my original Caste 1717 5mm shaft is turnded down from a 6mm, so the bearings etc use 6mm holes.

I think this is because they had a 6mm heli version, so they had a lot of rotors, and it was cheaper to turn the original ones down to 5mm then make a lot of 5mm ones, maybe that is the case with TP to? That they had a lot of 6mm or 8mm rotors laying around, or already being made for other motors? |

|

|

|

|

|

(#57)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

08.17.2015, 09:56 AM

My 1717 XO-1 version is the same 6mm shaft turned down to 5mm. Hard to tell if the shaft diameter is for technical reasons (e.g. vibrations or whatever) or if it's just because for a given type of application there is a "defacto-standard" like 6mm for some Helis or 5mm for 1/8 scale cars.

I got an answer from TPPower China (TPPower Europe forwarded my mail to them) in the meantime, they asked me some infos about my setup which I gave them. We'll see ... |

|

|

|

|

|

(#58)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

08.25.2015, 12:30 PM

Next fail.

Tried the TPPower TP5840S 1600V on 6s geared for 184kph (same as with the TP4070) in the meantime. Motor weighs 765grams. First test was with Torque Control set to 4.5 (like with the 1717 and TP4070). Didn't accelerate very well and maximum speed was just 135kph. Temps were around 50C after the pack. So obviously, Torque Control set way too low. What's weird, because the 4070, 1717 and 1515 required pretty similar values, all around 4 or 5. At first I thought it's because of different motor design or pole count and set it to 8.0 (Which is basically "off", with my other motors, everything above 6 becomes pretty much un-noticeable). With that setting, acceleration in low and mid rpms was very good, lots of torque, alot more than the 1717 and 4070. Cogging from a standstill was also alot better when compared to the 1717 or the TP4070. But it ran hot pretty fast (72C after a few mins) and I could only reach 165kph, had the feeling torque diminishes faster with higher RPMs than with the 4070 or 1717. The 4070 got 172kph with the same gearing. Also the 10AWG battery cables and EC5 connectors got quite warm, never had that happen before. ESC was also over 60C after a few minutes, usually it never goes above 50C, even in summer after a full pack. So it looks like that thing draws crazy amounts of current. Since a much higher torque control value was needed to get (nearly) the same topspeed, I think it is drawing those high currents mostly at high RPMs? I.e. it is inefficient at higher RPMs. Maybe another test with lots of hard acceleration but driving no faster than around 130kph will show if it's the RPMs that are causing this. If it stays cool then, I'd say 6-Poles are not for "higher" RPMs (that "losses get too high above 60k ERPM thing" Vedder talkes about on his Blog). Bummer, since I need around 35k RPM in the Slash because I can't gear taller. |

|

|

|

|

|

(#59)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 235

Join Date: Nov 2012

Location: The Netherlands.

|

08.25.2015, 04:06 PM

Little bit offtopic, but I like how you say you "just reached 135" :)

|

|

|

|

|

|

(#60)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 133

Join Date: Oct 2014

Location: Germany

|

08.25.2015, 05:51 PM

Wow, what a puzzle... I can't believe (won't accept :D) our big motor theory being blown to pieces...

Can't make any sense out of it yet. Patrick explained that the TC value is the Voltage drop (Current x winding Resistance) across the motor. So a higher TC value allows a higher motor Voltage drop before limiting Current... not sure where this story is going yet... Another thing Vedder said when talking about the power rating of my 4092: https://endless-sphere.com/forums/vi...esc&start=1000 Quote:

Like I told you, coincidentally, I'll gear my TP5660 for 184 kph no-load too, so will be very interesting to see how things compare. Just need to find a better spot to drive it. On a positive note though, the TP4070 actually did remarkably well, performance wise. Hope they'll send you a new one with better shaft soon. |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode