|

|

|

(#11)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

12.05.2007, 02:00 AM

So I've made some progress... But not much. I received my order from McMaster-Carr containing the 3 drill bits. After trying all 3, I was able to determine that this shaft is very hard.

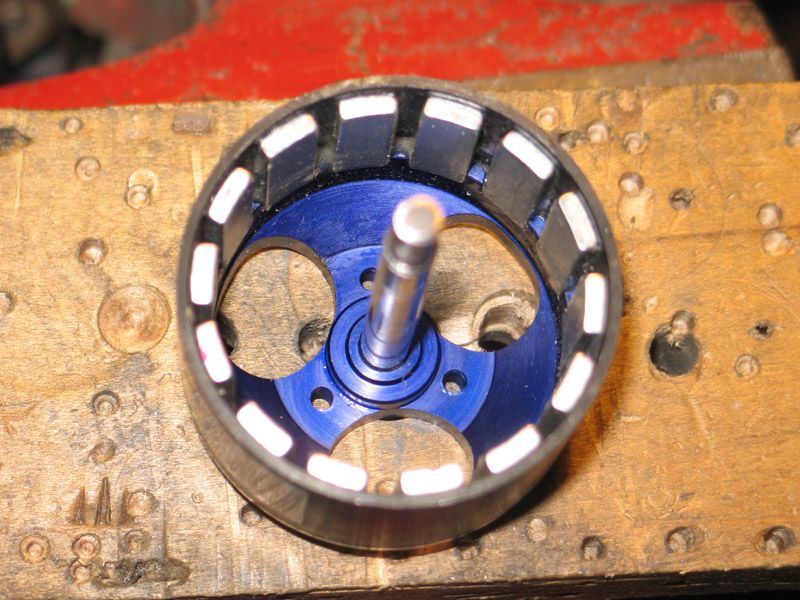

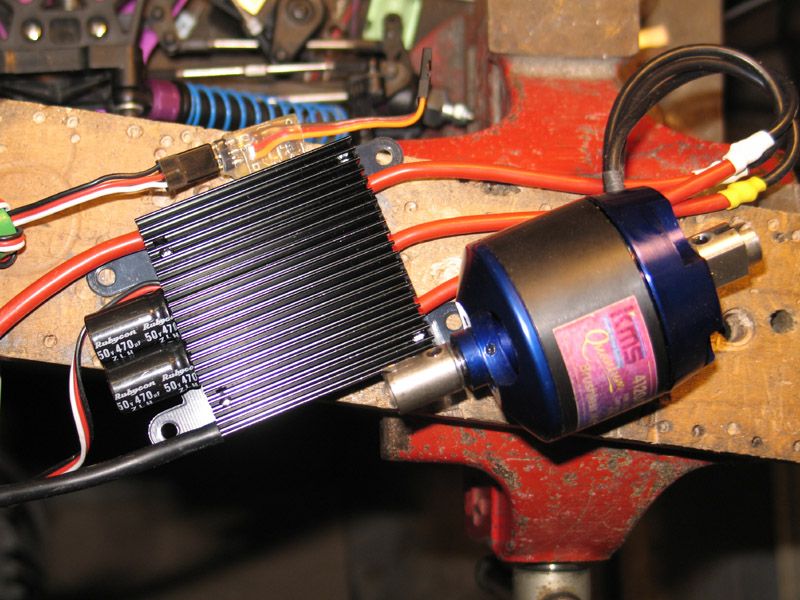

But in all seriousness, the steel used is harder than any other steel I have worked with. The 2.5mm carbide drill bit wasn't able to make any progress on it. I have an older 1/8" (3.17mm) carbide-coated drill bit that was able to penetrate, but it is of course a larger diameter than what it should be. All of this was after setting up my cross-slide vice on my drill press table, and setting it all up perfectly and tightening everything up. The use of oil made no difference. (jeez, I don't think I have made so many sexual references in one post) On to the pics:     And I also made a vid of the motor running: http://video.google.com/videoplay?do...27213169795459 The black disk I put on is the brake rotor. |

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Threaded Mode

Threaded Mode