|

|

|

(#46)

|

|

|

RC-Monster Aluminum

Offline

Posts: 764

Join Date: Apr 2008

Location: canada, quebec

|

09.22.2008, 09:25 PM

clean job,,!!!!!im always surprized when i see a mmmv2 (working unit

) )and aluminium is pretty hard to tap a small screw size

|

|

|

|

|

|

(#47)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

09.22.2008, 09:34 PM

hey mike, i just got a second MMM, running great so far

though i would hear the fan rubbing the case at times R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#48)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,402

Join Date: Aug 2008

Location: Twin Citys Mn

|

09.22.2008, 09:46 PM

Quote:

|

|

|

|

|

|

|

(#49)

|

|

|

RC-Monster Aluminum

Offline

Posts: 764

Join Date: Apr 2008

Location: canada, quebec

|

09.22.2008, 09:48 PM

brushlessboy16....lucky you are ...

me my second v2 failed after 30min.... me my second v2 failed after 30min.... friday....(i ship today to cc)i have one unit that my friend david lamontagne sold to me...(he run it about 2 hour so far) friday....(i ship today to cc)i have one unit that my friend david lamontagne sold to me...(he run it about 2 hour so far)lets see what happen this wek with this unit....

|

|

|

|

|

|

(#50)

|

||

|

RC-Monster Stock

Offline

Posts: 30

Join Date: Jun 2008

|

09.22.2008, 10:17 PM

Quote:

|

|

|

|

|

|

|

(#51)

|

||

|

Guest

Posts: n/a

|

09.23.2008, 12:21 AM

Quote:

I modded my case before I powered up my V2, I removed some material from the bottom of the case to make room for the fan connector and I also did a small amount of relief work for the induction coil. Regardless the BEC failed just after calibration with my radio. I beleive the case is a problem and is possibly causing a few malfunctions but believe a more likely explanation would be A: Faulty parts B: Assembly fault (my money is on this) I would think that after all the V1 failures that the CC techs would of gone over the design of the BEC with a fine toothed comb. This leads me to believe that the same problem from the V1's is also effecting the V2's. Is it possible an assembly technique is to blame here? Has anyone noticed how close the control board is to the back of the FET board? I wonder if when they solder these boards together there is some sort of issue??? Just some observations... I love CC  regardless regardlessWhat are everyone else's theories???? |

|

|

|

|

|

|

(#52)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,777

Join Date: Feb 2008

Location: Illinois

|

09.23.2008, 12:31 AM

Quote:

|

|

|

|

|

|

|

(#53)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 220

Join Date: Feb 2008

|

09.23.2008, 11:32 AM

Quote:

|

|

|

|

|

|

|

(#54)

|

|

|

RC-Monster Mod

Offline

Posts: 6,597

Join Date: Apr 2007

Location: NJ

|

09.23.2008, 01:41 PM

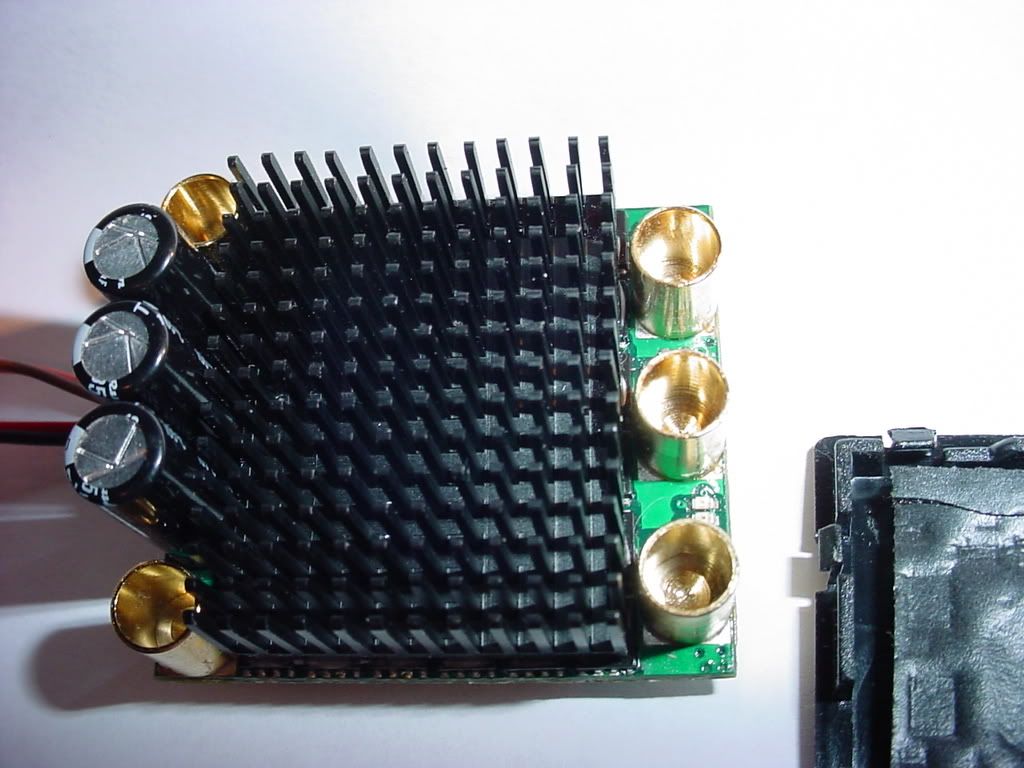

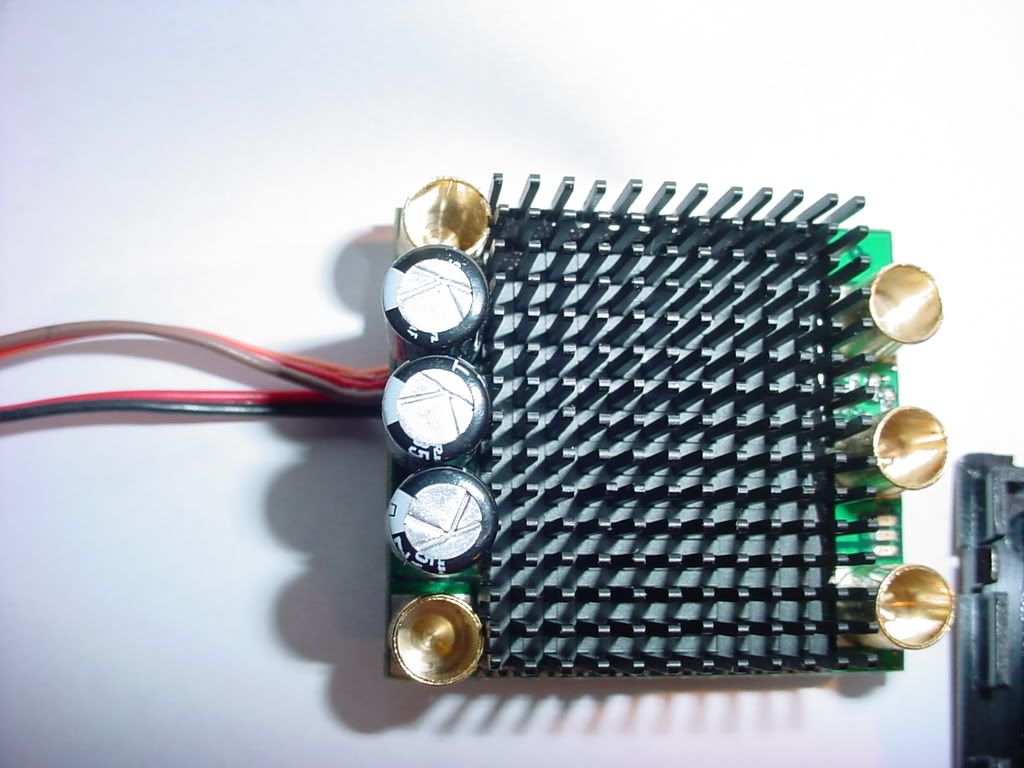

2nd the issue with the heatsink - I think CC should go back to soldered wires. The cups are way to close - I would say touching the heatsink.

The only thing that I believe is stopping a short is the laquerer that is put on - however when cleaning the esc with buggy blast and a compressor most of the laquerer came off so VERY worried about picking up a short. Personally leads are fine by me.... |

|

|

|

|

|

(#55)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 220

Join Date: Feb 2008

|

09.23.2008, 01:50 PM

Quote:

|

|

|

|

|

|

|

(#56)

|

|

|

RC-Monster Mod

Offline

Posts: 6,597

Join Date: Apr 2007

Location: NJ

|

09.23.2008, 02:23 PM

Not sure I could get tape or shrink down the back...

|

|

|

|

|

|

(#57)

|

|

|

RC-Monster Carbon FIBRE NOT FIBER!

Offline

Posts: 701

Join Date: Apr 2008

Location: Brisbane, Australia

|

09.23.2008, 06:58 PM

weird, mine are spaced out far enough to get at least tape perhaps a bit of heat shrink. I hadn't thought of this at all actually. thanks for bringing it up!!!

edit: u know, both the fins near my battery terminals are bent! this means they are touching/have touched.... also at the bottom i think the esc IS attached to them... im sure they would have thought about this a little???? perhaps its impossible to short for some random reason..? Monster Max Still Working... JR SX3 Neu 1512 2D/S 12t pinion 4800 zippy-r XRAY xt8 MMM Neu 1512 3D/F 11t pinion 6s 5000 Flightmax/ 4s 4000 Turningy |

|

|

|

(#58)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 220

Join Date: Feb 2008

|

09.23.2008, 08:45 PM

Quote:

|

|

|

|

|

|

|

(#59)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

09.23.2008, 09:34 PM

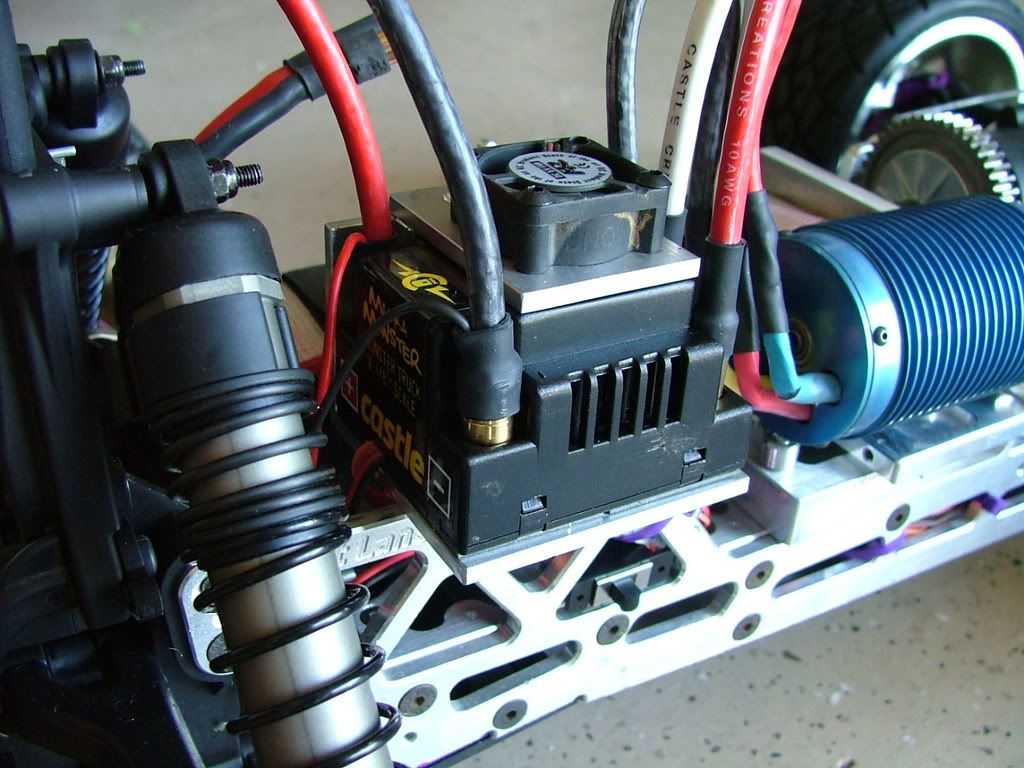

I've been following this thread. Very interesting points you guys are discovering. Jhautz also showed in detail about the possible fan plug issue.

I opened mine back up to check out the heat sink you guys have been discussing. I felt it was worth pictures. Here they are: In this first picture, please notice that my motor power cups have ample spacing.  In this picture, my power lead cups are touching the heat sink. Bent heat sink pins as previously mentioned.  This last picture shows the lower case mod that I did to create clearance for the fan plug. IMO, it's not necessary to go completely through the plate.  Please Note: In the upper right hand corner of this last picture, I found a resistor riding right on the support rail. I also removed material to clearance for that. What can I do about the power lead cups touching the heat sink? I don't have a good feeling about this. Those pins will flex/rub under shock and vibration I'm sure. IMO, this should have additional clearance to prevent problems. |

|

|

|

|

|

(#60)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

09.23.2008, 09:49 PM

Replace the connector with wire leads...

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

(just kidding Patrick!)

(just kidding Patrick!)

Linear Mode

Linear Mode