|

|

|

|||||||

|

|

|

Thread Tools | Rate Thread | Display Modes |

Kyosho D series 4wd Center Differntial - Motor Mount - Bearing ? Ideas |

|

|

(#1)

|

|

|

A Horse's Ass

Offline

Posts: 1,065

Join Date: Oct 2007

Location: Spokane WA

|

Kyosho D series 4wd Center Differntial - Motor Mount - Bearing ? Ideas -

01.08.2009, 02:27 AM

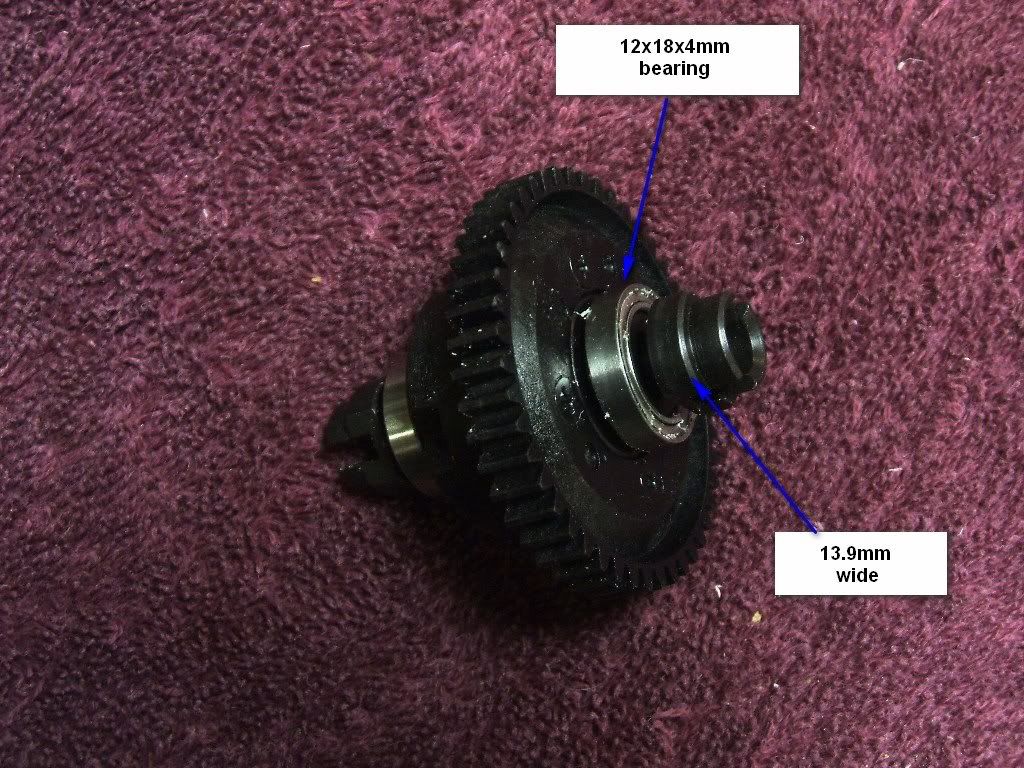

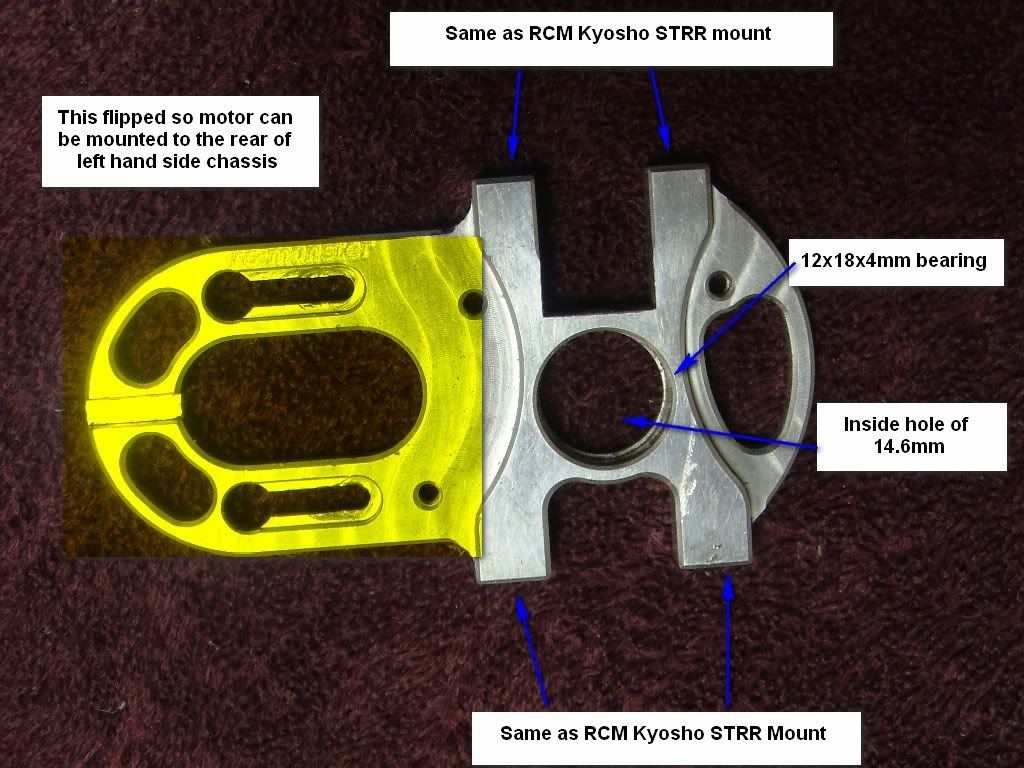

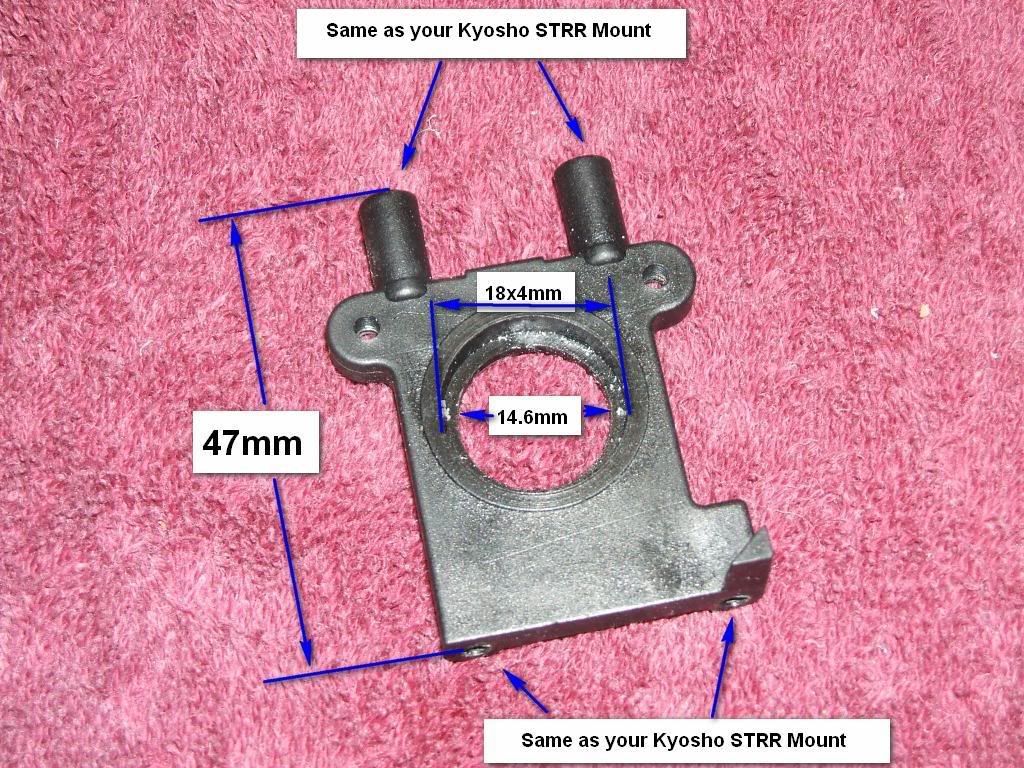

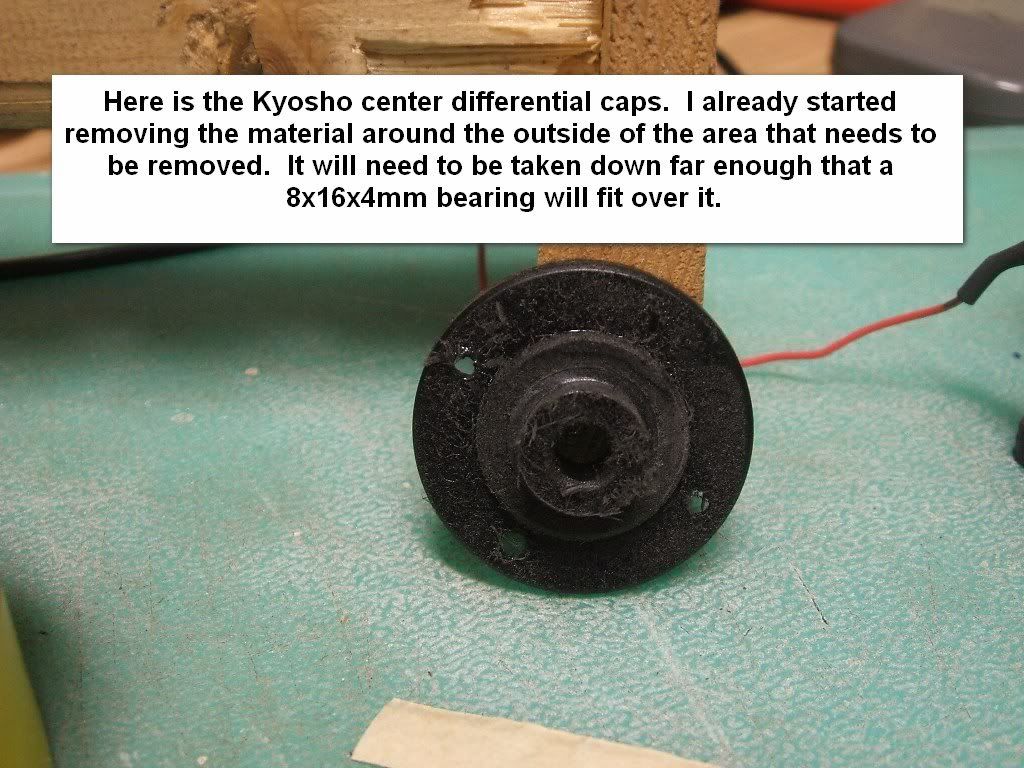

The question/problem here is getting the DST center differential to work with the RCM Kyosho motor mount. DST Conversion thread PICS. http://www.rc-monster.com/forum/showthread.php?t=17258 At the bottom of this thread there are pictures specific to this thread. Why it doesn't work: Problem with the Kyosho D series of 1/10th 4wd that Kyosho is putting out is the center differential output shafts require a 12mm bearing so they are using a 12x18x4mm bearing for the center differential. All of Mikes current RCM motor mounts fit bearings that are -- x 16 x 4mm. 16mm or less except for one the OFNA Ultra IIRC. It takes a 19mm bearing. The 1/8th scale center differentials that I have are all approx. 5-6mm wider/longer then the 1/10th scale differential in question. Using a 1/8th scale diff would require more mods/drilling the chassis and different length center shaft (probably). Will hold off on that option until there are not any others. As you look down the list of options I came up with. The odds of it actually working get better the higher the number. All the options using the RCM Kyosho mount will require the steering servo to be mounted on the other side of the chassis. 1. Use the Ultra Motor Mount then you would need a 19mm bearing. The inside diameter needs to be 12mm for the differential. I only found 12x19x4mm bearing in kits there were made by Acer for $100.00 and those have been discontinued. Not even sure if the mounting holes would match up with the Kyosho chassis. 2. To find a bearing that would work with the RCM mount and the Kyosho center differential would need to be 12x16x4mm. This would be the easiest if they could be found. I had no luck finding any bearings of that size. 3. Take the RCM Kyosho mount and increase the size for the bearing from 16mm to 18mm. I have the RCM mount here for my truggy and have looked it over. There is enough material around the current hole to increase it to the 18mm but it will require some patience and a steady dremel. At it's narrowest spot where the bearing will ride it is 20mm. That leave 1mm on each side. I have a hard enough time drawing a circle if I am tracing it around a glass. It will be a challage to get a real nice one for me. Easy to see what I mean in the picture. 4. Replace the Kyosho center differential with a CRT .5 center differential. Then use this with the RCM Kyosho mount. That would require a bearing of 10x16x4mm for the RCM mount side and also a mount from the LS10 center differntial or CRT. 5 for the other end with the LS10 10x15x4mm bearing. I did find the 10x16x4mm bearing at A Main. http://www.amainhobbies.com/product_...ducts_id/22757 The only problem with this option is just as you see above buying the crt .5 center differential and spur and mounts. For me personally, I would like to keep the Kyosho center differential setup with the plastic spur. I don't care too much for the metal to metal gear mesh. I’m going to try to avoid #4 for now. There also is the custom motor mount. I made one from 3/8” lexan that is working but a picture would only bring out the worst in you normally well manner people. :) Hopefully, the next one I am making will be done well enough I can take a picture to show you guys. Has there been a break through on a plastic spur that fits the CRT .5 differential? Anyone have the hot bodies center differential? I have the crt .5 in my LS10. Does anyone know where to get a bearing that would work for #2 above. Only one bearing is needed. Just one little bearing and everything would work out. Any Comments/ideas would be helpful. Thanks again for your help guys. Kyosho Center DIfferential  RCM Kyosho Mount  Kyosho DST Center DIfferential Bulk

|

|

|

|

|

|

(#2)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

01.08.2009, 02:43 AM

Ok, can you disassemble the dst diff for me?

My thought is to look at the part of the diff where the output comes out of. Is it one piece with the spur, or does the spur bolt over it, like a cap? I am guessing that it is made similar to the plastic kyosho spurs. Can you maybe use one of them to get a 10mm output insted of 12mm? Depending on the diff output size, most are 6mm, you should be able to turn down that area to fit a 10x16 bearing. Then do the same on the cup end and use a rcm kyosho mount and matching front bulkhead. |

|

|

|

|

|

(#3)

|

|

|

A Horse's Ass

Offline

Posts: 1,065

Join Date: Oct 2007

Location: Spokane WA

|

01.08.2009, 03:11 AM

The differential has the cap then you screw the spur onto the differential. Here's a link to the exploded views. You can tell me what part to look at. Snow is melting and a few strips of pavement have showed up on the street. I was just taking the DST out to see how it does on something beside snow. Will be back in a couple of minutes.

http://www.kyoshoamerica.com/downloa...7-exploded.pdf |

|

|

|

|

|

(#4)

|

|

|

Guest

Posts: n/a

|

01.08.2009, 03:16 AM

I would try and see if you can find an 18mm bit. preferably one used for milling that had a flat base.

|

|

|

|

|

|

(#5)

|

|

|

A Horse's Ass

Offline

Posts: 1,065

Join Date: Oct 2007

Location: Spokane WA

|

01.08.2009, 03:54 AM

I just received in the mail today a 15 and 18mm Forstner bit. For working on lexan and wood though. I doubt the would hold up for this job. It may work if I get the mass majority of material removed with a dremel the use the 18mm to finish out the hole and bottom.

Okay after looking at the exploded and a "normal" Kyosho spur here. I think I see what you are talking about James. If the cap that goes on the differential is a solid plastic "nipple" like the spur here and shaft is 6mm there should be plenty that could be taken of if needed. I'm placing an order for some wheel nuts and will add another diff cup and some 10x16s. Was hoping that once I got the DST I would be able to find a way to get it's differntial w/ the plastic spur to work in the LS10. Put that little head ache on hold for now. Good idea. |

|

|

|

|

|

(#6)

|

|

|

Guest

Posts: n/a

|

01.08.2009, 04:06 AM

You should be fine cutting aluminum as long as the bit is steel. (Preferably hardened) You won't be using it for that long and it will make a nice cut then what you could do with your dremel. IMO

|

|

|

|

|

|

(#7)

|

|

|

A Horse's Ass

Offline

Posts: 1,065

Join Date: Oct 2007

Location: Spokane WA

|

01.08.2009, 04:32 AM

Can you get hardened steel Forstner bits for 6 bucks a piece? LOL Made in China? I didn't go the expensice route, but if I thought I would be using it on anything other then platic or wood I would of. Then again it was only 6 bucks so once I get some motor mount templates made using the 18mm then I might give it a try. I can order another one (or better) later on. Is a higher RPM used when drilling in metals?

|

|

|

|

|

|

(#8)

|

|

|

Guest

Posts: n/a

|

01.08.2009, 04:48 AM

I bought a carbide saw blade from HR for 7 bucks the other day. Around 30 for a comparable blade at home depot and other hardware stores. Seems pretty much the same as the other ones i've used. Theres a lot of decent cheap stuff coming out of china these days

|

|

|

|

|

|

(#9)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

01.08.2009, 10:25 AM

Quote:

|

|

|

|

|

|

|

(#10)

|

|

|

A Horse's Ass

Offline

Posts: 1,065

Join Date: Oct 2007

Location: Spokane WA

|

01.10.2009, 03:33 PM

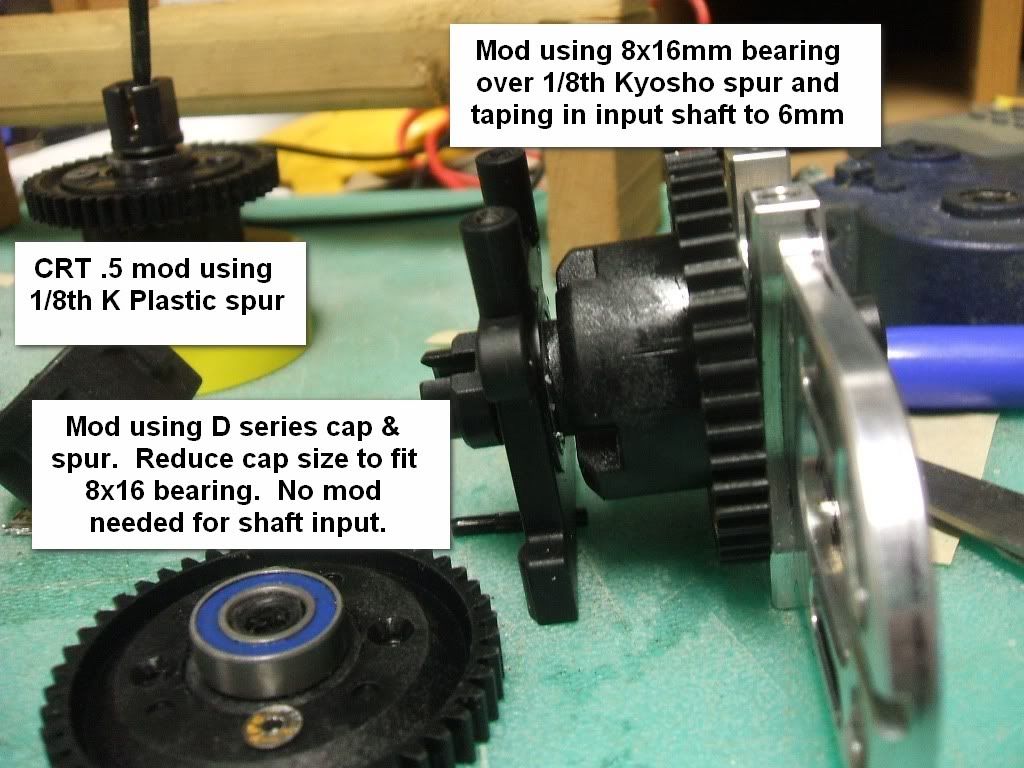

Thanks for the help. I gave both of the ideas you had linc a try to see how the would work. They both turned out good. One has a advantage over the other due to size of the dst shaft is 5mm though. I also took some time and got the plastic spur from kyosho to work on the crt .5 center differential. I use it in my ls10 so it will work in really any of the 1/10th scales that use a center differential. I will be putting together a write up on the mods needed for it. Now I need to finda new center cup for the crt .5 The manual doesn't list a part number an I can't find one on a-main. Maybe it is the same as the front/rear differential cup. They are just keeping it secret from me. You got a UPS box on the way to you. Got it out of here a few days ago.

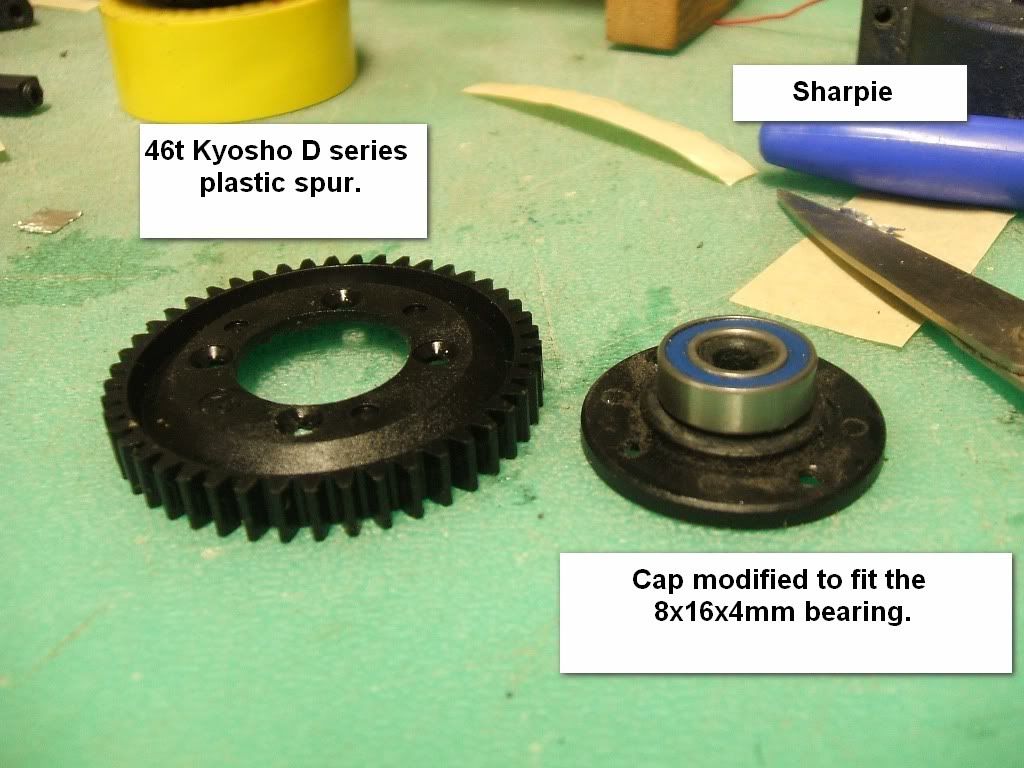

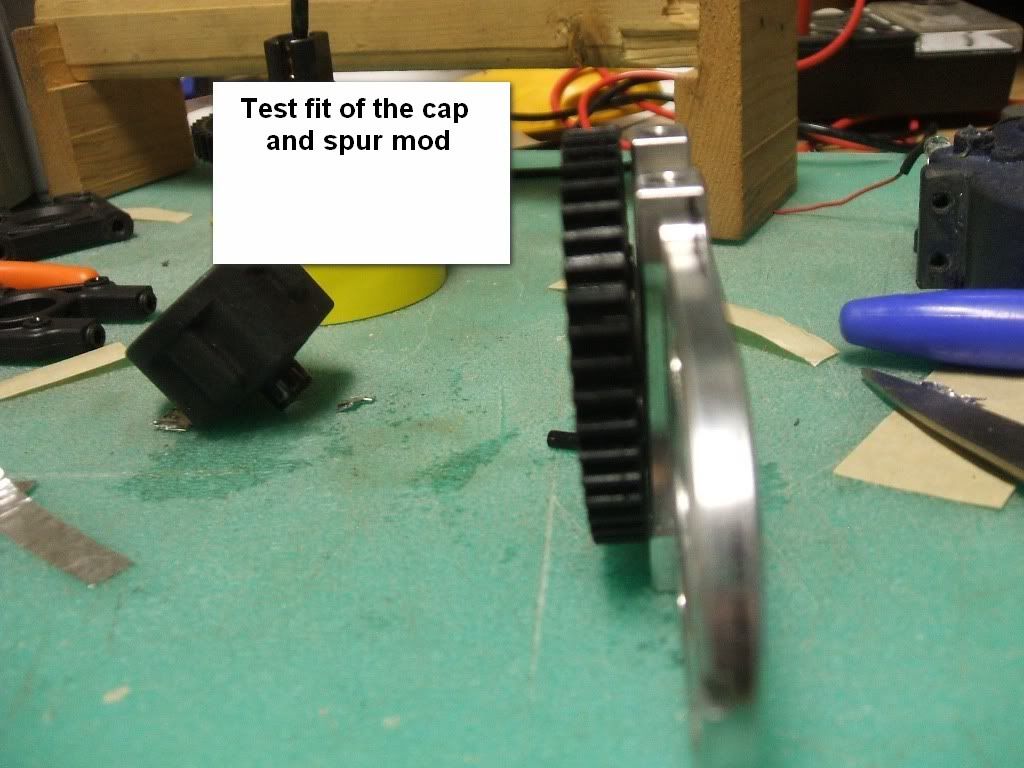

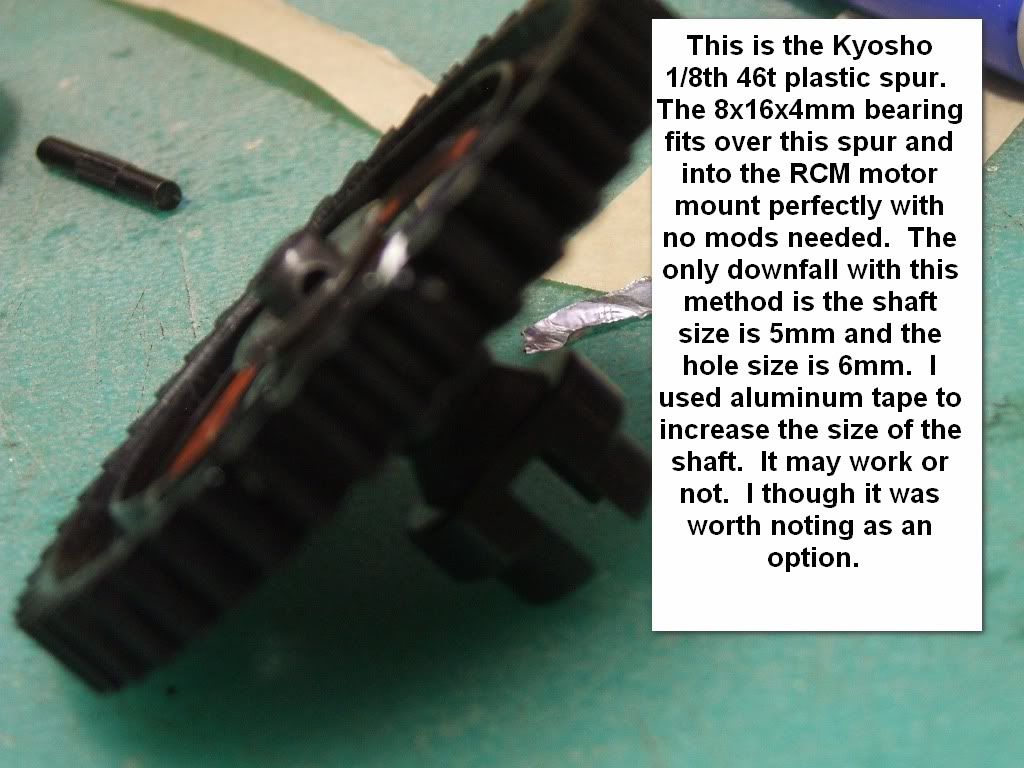

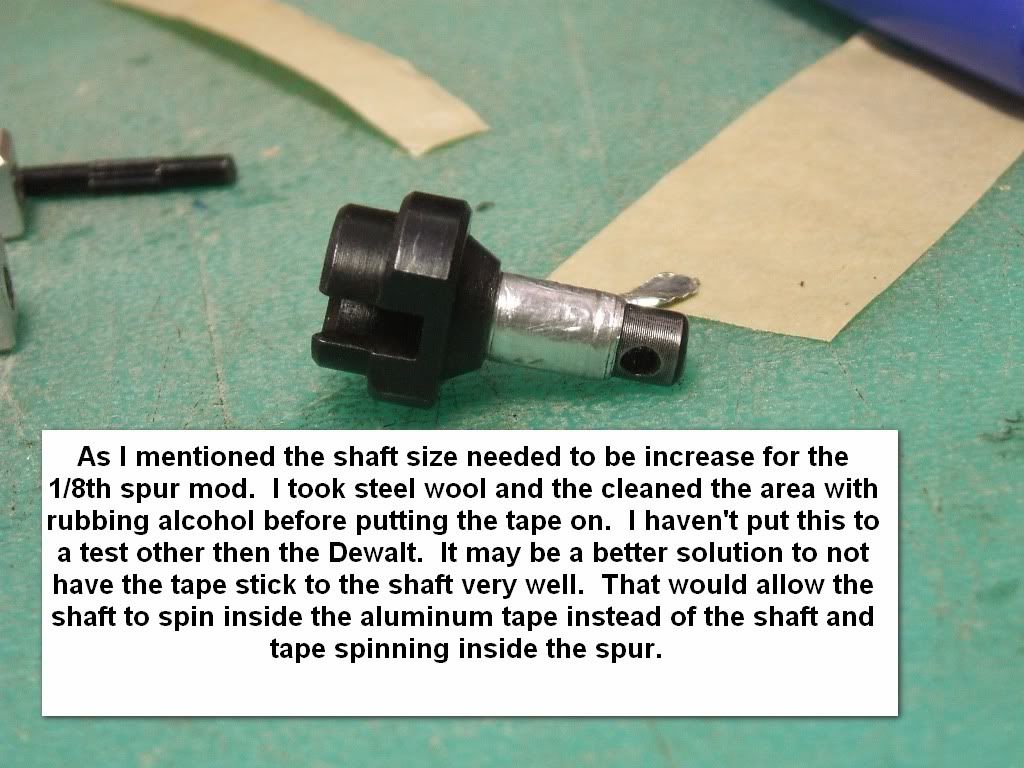

Here's what I've come up with. The mod to the existing cap and spur will work the best due to the 1/8th spur has a center hole of 6mm and the shaft on the axle drive is 5mm.        Back to the build thread about the problems with lining up the the RCM mount center drive axels and existing holes in the chassis. http://www.rc-monster.com/forum/showthread.php?t=17258 |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode