|

Losi 2.0 Conversion |

|

|

(#1)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 468

Join Date: Nov 2006

Location: Los Angeles, CA

|

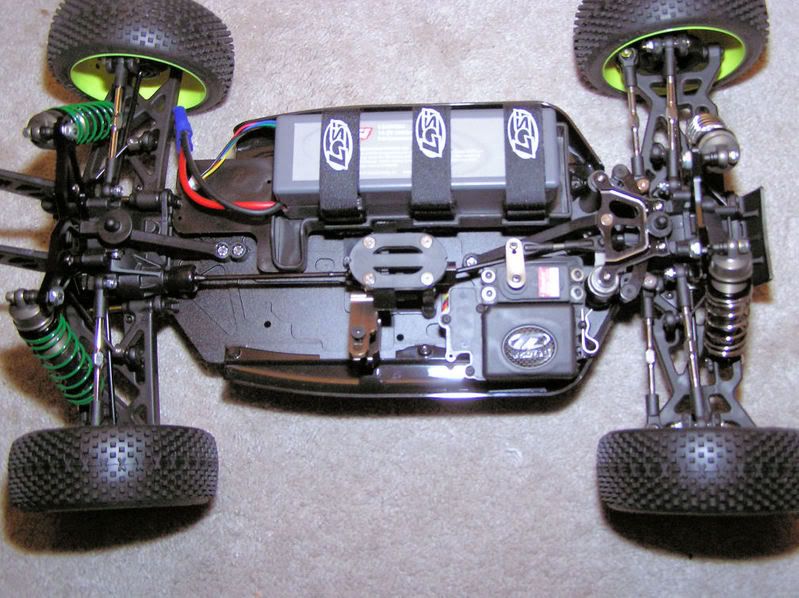

Losi 2.0 Conversion -

01.28.2009, 06:16 PM

Look what showed up today. Still need a body (the one that comes in the box has big holes in it for the nitro stuff) and I have not decided if I am going to use M3 or M4 screws to hold the motor onto the mount. Tapping new threads is not a problem but I noticed on the MMM motor the holes come very close to the endbell screws and there may not be enough meat on the endbell to provide support if I drill and tap for an M4 screw. Got to open up the motor and see what's on the other side of the endbell.

Losi 2.0 race roller, MMM 2650kv combo, Losi E-conversion kit. |

|

|

|

|

|

(#3)

|

|

|

RC-Monster Mod

Offline

Posts: 6,597

Join Date: Apr 2007

Location: NJ

|

01.28.2009, 09:06 PM

Sweet but need you'll need a pinion... i think the CC ones are 32p

|

|

|

|

|

|

(#4)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 468

Join Date: Nov 2006

Location: Los Angeles, CA

|

01.28.2009, 09:12 PM

Arct1k, the Losi kit comes with two Mod1 pinions (15T and 16T). Probably still need more pinions because you have to use a 45T spur with the kit so I may need to drop down to a 14T pinion.

|

|

|

|

|

|

(#5)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 468

Join Date: Nov 2006

Location: Los Angeles, CA

|

01.28.2009, 09:14 PM

Started the build, I put some M3 screws in the motor to see how it would fit. It seems ok, but I think I prefer the larger screws. In the first picture you can see the M3 screw sits way down in the hole, a larger screw would use all the surface area to spread out the torque, the M3 looks like it is using only half. Also a larger screw would have more surface area (threads) to engage the endbell, which will mean a stronger bond between motor and mount. You can also see in the picture how close the stock hole in the MMM motor comes to the endbell screw. I think an M4 screw will still be ok, need to pop the endbell and take a look. In the next picture (side view) you can see there is plenty of shaft (at least with the MMM 2650kv motor) for the pinion. I wish Losi would make some adapters that allowed you to use m3 screws (in case you didn't want to use the Losi motor). I was thinking of taking some 8-32 screws, cutting off the shaft, drill out the center and use a m3 bevel drill to make my own adapter, but it might be easier just to tap the motor endbell. You definetly need to grind the rear motor support when using the MMM motor.

M3 screw  Plenty of shaft  MMM 2650kv motor is much smaller than the 2200kv motor  Probably going to need to run a smaller pinion with a 45T spur. |

|

|

|

|

|

(#6)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,061

Join Date: Oct 2007

Location: Thousand Oaks CA

|

01.28.2009, 09:23 PM

Sweet conversion. I don't like the looks of the losi motor mount though.

|

|

|

|

(#7)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 468

Join Date: Nov 2006

Location: Los Angeles, CA

|

01.28.2009, 11:06 PM

BL_RV0, thanks. Yeah because of the sliding adjustment in the Losi mount there is a slight amount of play. I guess thats why they include a rear motor brace. I may switch to the RC-Monster mount, but I'll try the Losi mount first, the gear mesh adjustment is pretty cool.

|

|

|

|

|

|

(#8)

|

|

|

RC-Monster Stock

Offline

Posts: 44

Join Date: Nov 2008

Location: Fontucky! SoCal

|

01.29.2009, 05:04 AM

tits, Ill take that 15 tooth off you, if you want to get rid of it.

Brushless Traxxas Jato MM 5700 SH Z-Car MMM2200/5s4000mah Turnigy Packs |

|

|

|

|

|

(#9)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 316

Join Date: Nov 2006

Location: Helsinki, Finland

|

01.29.2009, 11:43 AM

Sweet build. Everything is nice and shiny. Can I ask how much have you spend on this now? Buggys has always been interest of mine..

|

|

|

|

|

|

(#10)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 220

Join Date: Feb 2008

|

01.29.2009, 12:35 PM

Shark, I helped a buddy with this exact conversion a few weeks ago. We did the same thing using the 3mm screws. He has been running it for like 3 practice days and they seem to be holding up fine.

|

|

|

|

|

|

(#11)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 468

Join Date: Nov 2006

Location: Los Angeles, CA

|

01.29.2009, 02:51 PM

Quote:

Yeah several people have reported the M3 screws are working ok, but I still would like to try the M4 screws. Tapping is not a problem, and I just opened up the motor and there appears to just be enough room inside for the larger M4 screws. The motor has 2 sets of holes, so I'll tap one set to take M4 and leave the other at M3 size, so I can have both, in case I put the motor in a different mount. |

|

|

|

|

|

|

(#12)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 468

Join Date: Nov 2006

Location: Los Angeles, CA

|

01.29.2009, 02:56 PM

A lot of $$$.. I used a discount coupon on the Losi 2.0, and another for the MMM, so I saved a few bucks, but it still not cheap. This will be my 5th buggy conversion, I have learned a lot with each build, so hopefully the Losi will turn out ok.

|

|

|

|

|

|

(#13)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 468

Join Date: Nov 2006

Location: Los Angeles, CA

|

01.29.2009, 02:59 PM

Quote:

Sorry SeanZ0r, but I can still use the pinions on my truggies. I am curious, several people have said they are having issues with the Losi pinions coming off because the grub screw is too small and can't be properly tightened. Did they change the design? Because these pinions have the same size grub screw as the RC-Monster, Novak and Robinson pinions. |

|

|

|

|

|

|

(#14)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 316

Join Date: Nov 2006

Location: Helsinki, Finland

|

01.29.2009, 05:40 PM

|

|

|

|

|

|

(#15)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 468

Join Date: Nov 2006

Location: Los Angeles, CA

|

01.29.2009, 11:46 PM

Another update: I have added the radio tray and steering servo, optional aluminum servo saver arm, losi servo horn and a King Headz steering plate. I have a Losi hard case battery in the first picture, it's a pretty big battery much bigger than the Neu or Zippy.

Losi battery  Neu battery  Losi on top, Zippy in the middle Neu on the bottom all are 25C 4S lipo's.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

. We'll see, these are very tempting right now..

. We'll see, these are very tempting right now..

Linear Mode

Linear Mode