|

|

|

(#46)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 174

Join Date: Dec 2007

|

06.12.2009, 09:45 AM

Someone might want to go down the road of "supply batteries" while stuff is being gathered:

I had originally thought that perhaps users might send me packs in the off season. I've bought a number of used lipos, but you never know what you're going to get so any comparisons are skewed. The shipping twice also runs the cost up to high. A fair way might be to have the vendor/assembler send you a pack and if cycles or other tricks/tips make the performace better then so be it. Have them send the pack at whichever point they think is best knowing you may do a half dozen tests or so. This gets rid of any discrepency for cycle life and cycle currents. I've found that a brand new pack always performs best and continues to degrade at every cycle. If they believe that 20 cycles is the best point then so be it, they send you one with 18 cycles on it. Just trying to think ahead. |

|

|

|

|

|

(#47)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

06.15.2009, 08:25 PM

Well, despite all the less-than-ideal factors in my design, I went ahead and got 220 50w 3ohm resistors. Retail price would have been almost $400 + shipping, and I got them for ~$80 shipped. More than I wanted to spend really, but I could always use extras for various power projects.

Once they come in, I'll size up some cheap PC surplus heatsinks from BGMicro or AllElectronics to cool them. To test 2s up to 150A, I'll be using 60 resistors in parallel  . Which is nice because I'll make banks of 5-6 on each CPU heatsink and just add them in the circuit depending on the max current I want to test at (and use the ESC to go from 0A up to the max value). I'll probably use some 8-10GA car audio wire for the cabling. . Which is nice because I'll make banks of 5-6 on each CPU heatsink and just add them in the circuit depending on the max current I want to test at (and use the ESC to go from 0A up to the max value). I'll probably use some 8-10GA car audio wire for the cabling.So, the process moves on... slowly but surely. |

|

|

|

(#48)

|

|

|

RC-Monster Spudgunner

Offline

Posts: 2,353

Join Date: Apr 2008

Location: South Dakota

|

06.15.2009, 08:57 PM

Great to hear an update! Keep us informed and remember what a thread is useless without...

|

|

|

|

(#49)

|

|

|

Soldermaster Extraordinaire

Offline

Posts: 4,529

Join Date: Apr 2007

Location: Plymouth, MA, USA

|

06.16.2009, 01:19 AM

|

|

|

|

|

|

(#50)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

06.16.2009, 03:10 AM

OK, I'll bite; what are the pitchers for?

|

|

|

|

(#51)

|

|

|

RC-Monster Spudgunner

Offline

Posts: 2,353

Join Date: Apr 2008

Location: South Dakota

|

06.16.2009, 12:53 PM

|

|

|

|

(#52)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

06.16.2009, 01:31 PM

lol, ok, I get it. "Pitchers" = "Pichers" = "Pictures". It was late last night. That's my excuse anyway.

|

|

|

|

(#53)

|

|

|

TEAM FUSION

Offline

Posts: 2,041

Join Date: Jul 2006

Location: Iowa... Hawkeye country

|

06.16.2009, 02:20 PM

or maybe you had one too many pictures of beer last night?

Losi 8IGHT MM/Neu 1512 1900kv Kyosho 777 T4 MM 5700 B4 LRP XX4 MM 7700 old losi xxcr, MM4600 4s lipo 70mph+ |

|

|

|

|

|

(#54)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

06.16.2009, 03:44 PM

lol, I rarely drink, so that's not it.

|

|

|

|

(#55)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

06.16.2009, 04:09 PM

Cool Brian, I'm looking forward to seeing how it turns out. :)

|

|

|

|

|

|

(#56)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

06.22.2009, 11:31 PM

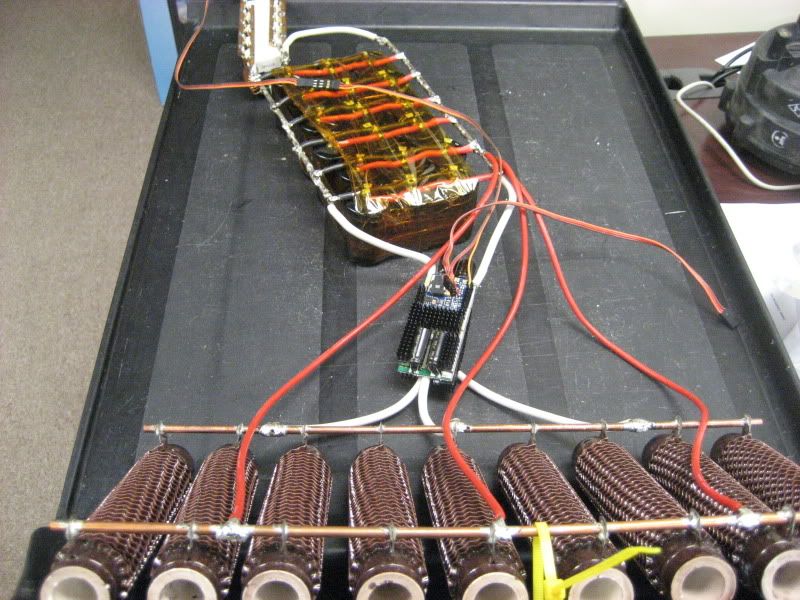

A few resistors anyone? The CRT.5 in the background is for size reference. And don't mind the duct-taped body - I never said I was a good driver.

So, stage 1 complete (getting the resistors). Now for the expensive stuff (Eagletree, MMM ESC, etc)... |

|

|

|

(#57)

|

|

|

RC-Monster Spudgunner

Offline

Posts: 2,353

Join Date: Apr 2008

Location: South Dakota

|

06.22.2009, 11:33 PM

Keep us updated! That's awesome!

|

|

|

|

(#58)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,697

Join Date: Mar 2008

|

06.25.2009, 07:27 PM

Funny how minds work alike. Here is Castle's version:

We are using the new datalogging ESC (Phoenix-ICE 200) to store data from the battery discharge. 9 x 400 watt resistors, 18 x 33,000 uF capacitors and 6 x common mode chokes to keep the battery load as DC-like as possible. President, Principle Engineer Castle Creations |

|

|

|

|

|

(#59)

|

|

|

TEAM FUSION

Offline

Posts: 2,041

Join Date: Jul 2006

Location: Iowa... Hawkeye country

|

06.25.2009, 07:32 PM

Very nice PD :)

Losi 8IGHT MM/Neu 1512 1900kv Kyosho 777 T4 MM 5700 B4 LRP XX4 MM 7700 old losi xxcr, MM4600 4s lipo 70mph+ |

|

|

|

|

|

(#60)

|

||

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

06.25.2009, 08:46 PM

Quote:

I picked up an Eagletree 150A logger from a member here so that is taken care of, but the ICE would work just as well. I picked up an Eagletree 150A logger from a member here so that is taken care of, but the ICE would work just as well.Looks like I'm gonna have to get some caps as well. I assume by the size of yours and the value of yours that they aren't low-ESR? I suppose it's not needed with that amount of capacitance. Maybe a 0.5-1F car-audio cap would work (and probably cheaper). I imagine the hook-up spark is VERY substantial though - or are you using a no-spark resisitor? My design didn't include chokes - maybe I should look into that as well. I could probably pick up a large toroid (or unwind a spare large transformer I have laying around) and wind one myself. What is the total inductance value of your setup? What are you using for the throttle control signal; an actual radio, a seperate circuit (like I planned), or using some computer driven control signal? I would LOVE to have a computer-driven control signal so that I can program test runs and have it be consistent for all battery tests. So, if your setup uses a computer-driven setup, PLEASE let me know!  Thanks for your input Patrick. At least I know I'm on the right track; if it's good enough for CC, then it's good enough for me!

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode