|

D8e |

|

|

(#1)

|

|

|

RC-Monster Stock

Offline

Posts: 10

Join Date: Jan 2009

|

D8e -

07.01.2009, 10:09 PM

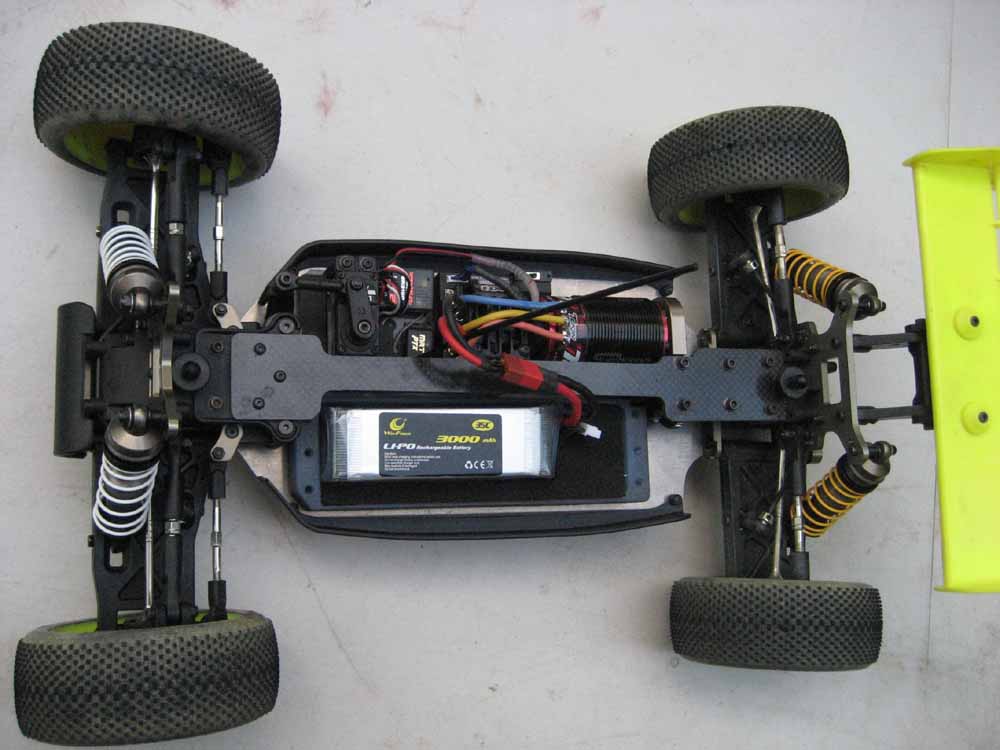

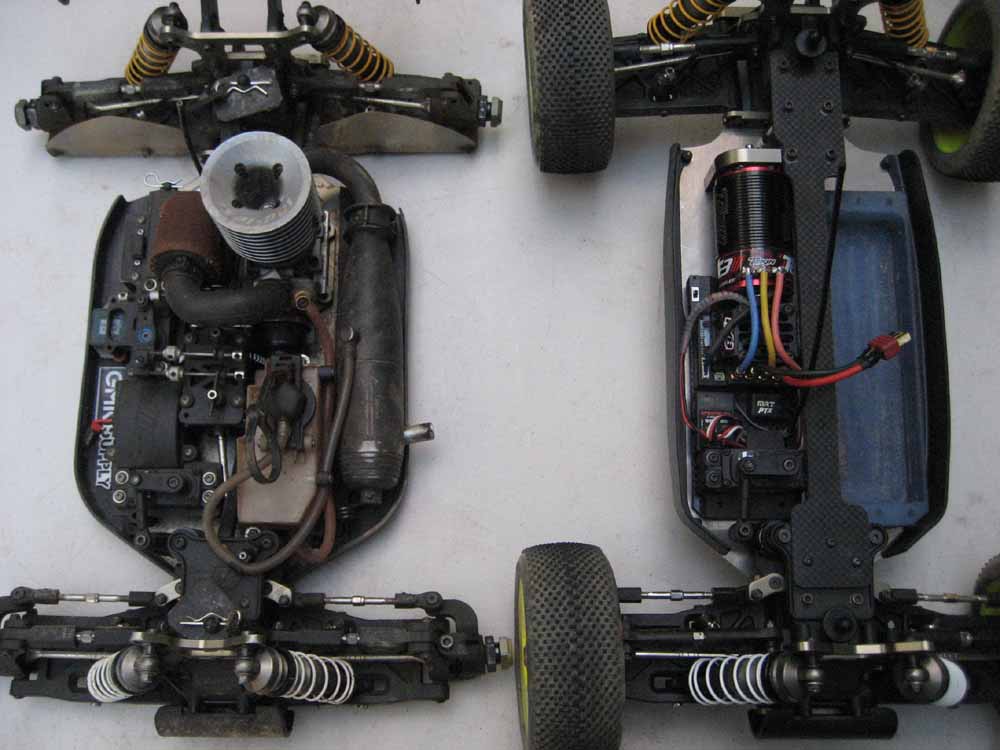

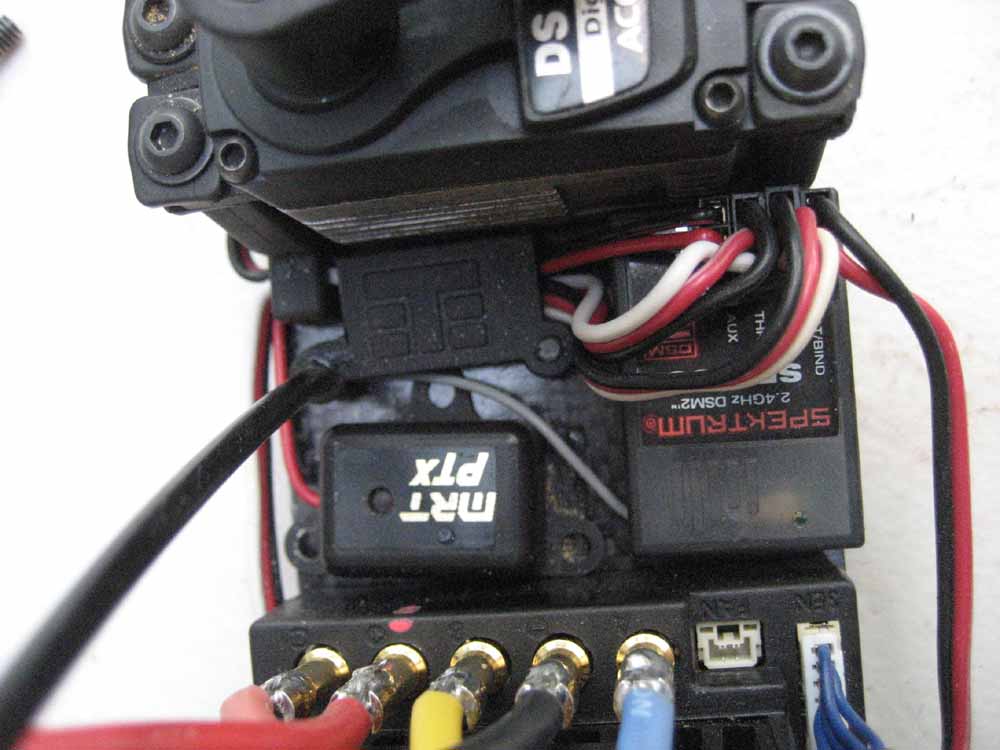

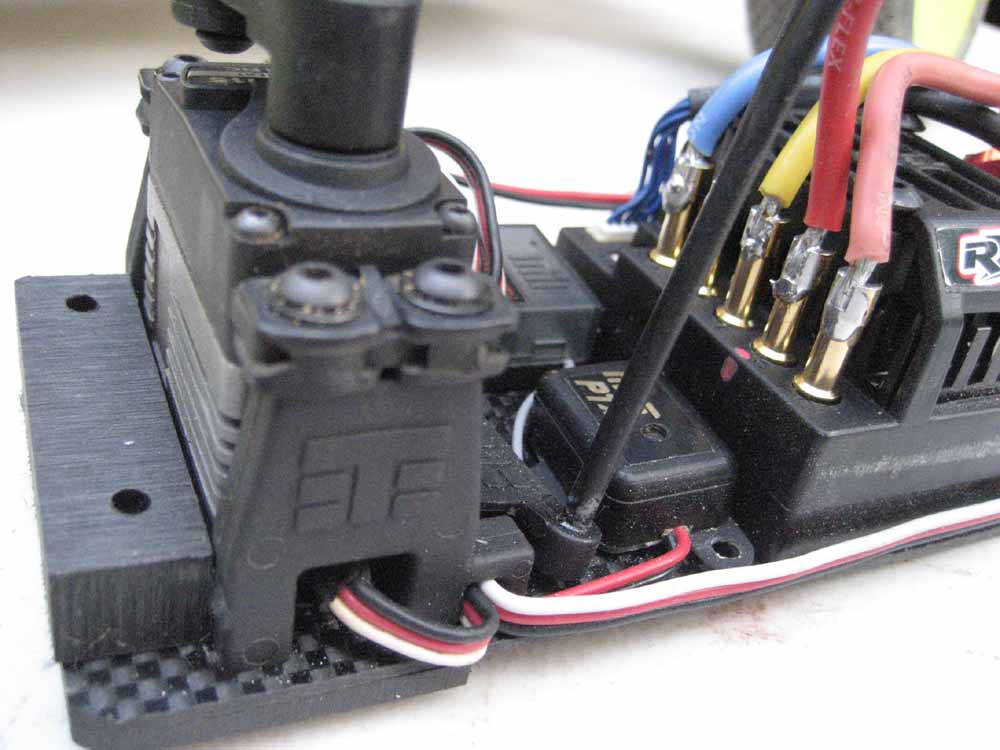

After 6 months of on and off work, and several false starts, I pulled an all nighter this past Saturday and finished my Hot Bodies D8E at 8:30 Sunday morning - and it was on the track racing by 11 that morning. I'm really pleased how it turned out, both in terms of how it looks, and how it runs. My original plan last fall was to build a 1/8th version of my Kyosho ZX5, complete with a center slipper in place of the center diff. After several months of work on the slipper, I abandoned that plan when someone told me the Hyper 9 nitro comes with a 40T center diff. 40T was the magic number, because a 40T spur was the maximum OD I could run and have the center diff mate directly to the rear clip. I started working in that direction, including new motor mounts and center drive shaft. Then, Hobao released the pictures of the 9E, and I decided to sit back and wait till it came out, so I could use that car's motor mount, diff mount and center drive shaft. I was also committed to run the new Tekin RX8 system, so I was waiting on that. In the meantime, I made the battery box, chassis (two versions before I got one I was pleased with) and a few other bits and pieces. I didn't need to buy a whole D8 kit, because I only needed the front and rear clips, so I just bought assemblies from kit parters on Ebay.

I spent the most time, besides the aborted slipper, thinking about how to make a simple, compact and easy to remove radio tray. After racing a number of nitro buggies the last 5 years, I really came to appreciate how easily the HB and Losi radio trays are to remove, which you do all the time with 1/8th buggies. At the same time,even the cleanest E conversions I saw looked harder to work on than the worst nitro buggy. I finally came up with a tray that holds all the electronics - even the on/off switch and radio antenna - and that mounts with only three 4mm flathead screws from the bottom of the car, with no nuts used. Disconnect the tie rod from the steering servo to the rack, remove the two 4mm motor mount screws, slide off the pinion, and then take out the 3 flatheads from the bottom and slide the tray out. Less than a three minute job - faster than any nitro buggy. The car is really narrow, and I couldn't find any narrow 1/8th bodies. Even a body like a Losi electric or nitro is much wider than this car, which is only 5 1/2" wide from the outside of the mudguards side to side. None of the Hot Bodies team guys I talked to had an extra D8E prototype body I could have, so I decided to make a mold and vac form my own - another whole set of skills to learn. I still don't have a perfect cast, but I'm getting closer. 040 Lexan isn't easy to mold, so I may try PETG as an easier to work with alternative. I ran it for the first time yesterday at a club race - I think there were 7 or 8 cars in the E8 class. With 3 minutes of practice, since I only had one pack, the car missed TQing by one second, and then went on to lead and win the 10 minute main - a good debut. I ran a Tekin 1700 buggy motor on a two 4000 35c packs - this club requires hard case packs, so I couldn't run my smaller lighter 5S. The Tekin system worked flawlessly. This is a very small track with moderate traction at best, so 4S was plenty - I worked on not spinning the wheels and staying smooth. The car was very easy to drive - with the weight so centered, the car rotated very well, and had plenty of steering. I only used 1800 mah in a 10 minute main with 30 seconds of warmup - only about 170 mah/minute. The motor only temped at 118, so I could definately go up a tooth or two on the pinion. I ran 15/40, with the HB 10/43 gearing in the diffs. 0 timing, 2 on the throttle curve, no amp limiting. The combination of the car's layout and the Tekin powertrain yielded a very smooth, easy to drive car. A few more details - the chassis plate is 3mm 7075-T6. The battery box is nylon, the radio tray is made out of 1.5 and 3 mm carbon fiber. The top stiffener and the battery box holder is 3 mm carbon fiber as well. With the two 2S hard case packs the car is 8 lbs 1 ounce; with the lighter 5S 300 30C soft pack the car is 4 ounces lighter. It is not a particularly light car - the HB clips are not light - but it feels light, is very simple to work on, should be durable, and like the D8, it feels lighter on the track than its weight would suggest.           __________________ Gary GMK Supply www.gmksupply.com Great products. Goofy names. |

|

|

|

|

|

(#2)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,061

Join Date: Oct 2007

Location: Thousand Oaks CA

|

07.01.2009, 10:23 PM

That is a seriously nice conversion. Those lipos are crap though- I had some 3s 2800mah 30c packs that didn't last 2 runs... Love the custom body tho- you don't see them much!

|

|

|

|

(#3)

|

|

|

RC-Monster Mod

Offline

Posts: 6,597

Join Date: Apr 2007

Location: NJ

|

07.01.2009, 10:28 PM

I can attest that this ran very well... although the body looks like a banana ;) Sucks to be beaten by a banana!

I think the weight it all in that chassis - you need to get it to mike to mill some cutouts. Please don't build a truggy! lol |

|

|

|

|

|

(#4)

|

|

|

RC-Monster Stock

Offline

Posts: 34

Join Date: Aug 2008

Location: Huntsville, Al

|

07.02.2009, 12:34 AM

Good Job! I like to see custom projects work.

|

|

|

|

|

|

(#5)

|

|

|

RC-Monster Aluminum

Offline

Posts: 538

Join Date: Apr 2007

|

07.02.2009, 02:05 AM

Very nice, I love the electronics tray.

|

|

|

|

|

|

(#6)

|

|

|

"1.21 GIGAWATTS!!!"

Offline

Posts: 523

Join Date: Nov 2007

Location: Sacramento

|

07.02.2009, 02:12 AM

+1 on the tray...looks super clean..

MMP/1410 3800kv 2s 65C 5600mah proteks Dx3s |

|

|

|

|

|

(#7)

|

|

|

RC-Monster Stock

Offline

Posts: 10

Join Date: Jan 2009

|

07.13.2009, 01:21 PM

Nice chatting with you yesterday, Mike!

|

|

|

|

|

|

(#8)

|

|

|

RC-Monster Mod

Offline

Posts: 6,597

Join Date: Apr 2007

Location: NJ

|

07.13.2009, 01:37 PM

Mike made it to DR? Bugger I had to miss yesterday!

|

|

|

|

|

|

(#9)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,150

Join Date: Jan 2005

Location: wolcott ct

|

07.13.2009, 10:05 PM

That is a very nice conversion. Checked it out the other week when you were at wolcott hobbies.

Hyper 9e, mmp,tekin 1900kv Associated sc10 4x4, novak 4.5 |

|

|

|

|

|

(#10)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 4,236

Join Date: Dec 2007

Location: Cape Cod, Mass.

|

07.13.2009, 10:35 PM

Nicely done

2. MBX-5T 1520, MMM ON 5S 3. MBX-5 ONROAD CONVERSION 1515, MMM ON 5S 4. MRX-3 ON ROAD CONVERSION 1512, MMM ON 6S 5. TEN T 2650 T8, MMP ON 3S |

|

|

|

|

|

(#11)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 392

Join Date: Nov 2008

|

07.16.2009, 01:49 AM

Wow, a wood mould for a customized lexan body, Nice Job.

|

|

|

|

|

|

(#13)

|

|

|

RC-Monster Stock

Offline

Posts: 34

Join Date: Aug 2008

Location: Huntsville, Al

|

07.29.2009, 02:22 PM

Gary NJ

What CVD's are you using front to rear? |

|

|

|

|

|

(#14)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,150

Join Date: Jan 2005

Location: wolcott ct

|

07.29.2009, 06:38 PM

If I had to guess I would say the hyper 9e drive shaft. He also using the hyper 9e motor mount.

Hyper 9e, mmp,tekin 1900kv Associated sc10 4x4, novak 4.5 |

|

|

|

|

|

(#15)

|

|

|

RC-Monster Stock

Offline

Posts: 34

Join Date: Aug 2008

Location: Huntsville, Al

|

08.02.2009, 10:11 PM

I meant to say front and rear cvds, going to the wheels.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode