|

|

|

(#33)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.08.2010, 10:11 AM

In the meantime, I was looking at making a DIY thermoformer. Looks quite easy to do actually. I was thinking I could use one of these to mold an ABS battery box. However, so far I'm not happy with my layout options.

The big 1520 takes up so much room in the tvps, its going to be really difficult to cram it, two str servos, as well as all the electroncs. The only option I really see is to offset it along side the servos, or just say to hell with it and just mount the entire thing dead center and hang my batt boxes on the side again. I really like my batt boxes, and they are larger than std. Its less elegant than having everything inside, but may actually be better performance-wise. With the 4ws, the pivot point of the truck tended to move to the center, It would make sense to have most of the weight centered there. The batt boxes also sit lower than I can get them in the tvps, so cg would be better also. It would leave lots of room inside for electronics, and make everything easy to work on. IDK at this point.. have to ponder it a while... |

|

|

|

|

|

(#34)

|

||

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.08.2010, 10:18 AM

Quote:

OTOH, they've paid for people to do all sorts of classes/degrees only loosely related and paid for the whole thing. This class is only $400 (we have $10K/yr max benefit) and I end up doing a lot with instrumentation and custom system building, so I think I can work it in. If I can do that class, the next class is in CAD.  Want to work on an MBA too, just so little time as it is w/ the kids |

|

|

|

|

|

|

(#36)

|

|

|

Guest

Posts: n/a

|

10.08.2010, 02:47 PM

Thanks for the videos Bondo.......I am more pumped about getting my 1717 now. I hope Castle soon has an 8-10s ESC. You mentioned the lipos getting warm, how is the ESC holding up. I would think the 1717 and the 1520 both would put a MMM through its paces. Either way exciting time to be an electric RC fan!

|

|

|

|

|

|

(#37)

|

|

|

Guest

Posts: n/a

|

10.08.2010, 02:56 PM

Hey Finn, (Sorry not trying to jack the thread) I want to get an MBA too, I am down the road from Va Tech and I know they have a one night a week MBA program and you get the full Pamplin MBA (<--Tech's B school). And there was talk of moving to some kind of team building system where they cut down to 2 times a month with the prof, then email with your team on assignments. I know you are in PA, not VA but if you haven't talked with a bigger school close by, you might see what they have to offer. You have some GREAT business schools in PA! (Wharton anyone......5th ranked and personally I think is should be higher than that, based on what I have seen out of Harvard grads!)

Sorry back to talking about torturing a poor Savage with a 1717! |

|

|

|

|

|

(#38)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 233

Join Date: Sep 2009

Location: Australia

|

10.08.2010, 07:09 PM

Quote:

Will be great to see some vid of it when finished. I enjoyed watching the vid of your previous 4WS build and its unusual look when turning. Btw, you might find that with the cutout you have for the slipper that rocks will get stuck under the adjustment ring as its diameter is much larger that of a normal center diff case. That's why my cutout is as wide as it is. |

|

|

|

|

|

|

(#39)

|

||

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.08.2010, 09:06 PM

Quote:

I'm glad you liked the vid. It was pretty short and crummy, but just something to show the 4ws in action. Meant to make another vid, but have barely drove it this yr. |

|

|

|

|

|

|

(#40)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.12.2010, 06:03 PM

I made a better template using acrobat. The one attached earlier is handdrawn and scanned. This one I added lines digitally to be sure they are square and they print darkly. You have to tell the printer to print comments for the lines to print. Kinda lame, but Adobe is teh ghey.

I may end up cutting another template with a shorter wheelbase. The bug body I want is really suited for 480mm wb and I'm worried it may be too long to look right, but IDK at this point. Since I may bail on the batts inside the tvps, there is not much point to the bit extra length. Prolly buy the body and compare the two templates before I make any cuts into my alu stock tho. |

|

|

|

|

|

(#41)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 453

Join Date: Mar 2006

|

10.27.2010, 11:15 AM

Any updates?

|

|

|

|

|

|

(#42)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.27.2010, 04:29 PM

Not too much, I've been away on a long vacation, just got back, and have family in town for my daughter's birthday. Not much time to do much with it.

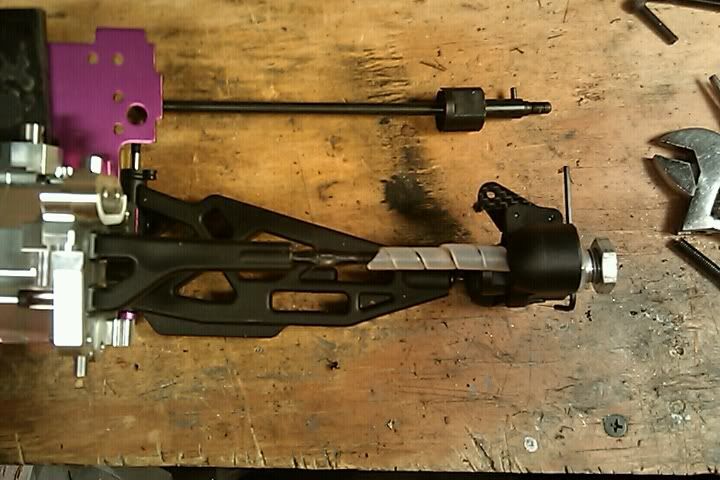

Looks like the MMM XL will be out soon, so gonna have to get my azz in gear tho :) I did get in the Mugen arms and carriers before I left and did some sizing up to get a rough idea if it can work. The bottom arms should be fairly easy to mount. Just a couple spacers will be needed. I will have to remove the material where the lower arm pins go thru on the FLM bulkhead. The arms will just be held by the braces truggy style, which should be fine. Making me a bit nervous to go hacking up the bulkhead just yet tho. It did seem like I will gain about 8-10mm ea side over the XL width tho. That's w/ 0 offset hubs also. Offset hubs can push that to 20+mm. Its hard fought for a bit of width, but hopefully its worth it. I don't need to do anything that will ruin the bulkheads if I decide the mugen arms don't work out well and decide to go back to the Sav arms. If anything, str should be the same, but a little less weight and nowhere for pins to bend in and get stuck.  As I thought, the ugly bit will be to figure out the top arms. Here's a pic of the Sav adj arm mounted to with the mugen arm. The arm is way shorter. so I need either a long turnbuckle and some type of coulper to attach the pillowball, or find some way to use the Mugen upper arms. I'm worried this will be the weakpoint in the design. Got a couple ideas, but nothing great so far.

|

|

|

|

|

|

(#43)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

10.27.2010, 04:43 PM

Also, the shock mounts will sit a bit more forward, so I can use the LST shocks easy enough if I want to keep them, or have plenty of room for other shocks depending on how I want to go. In the interest of $$$, I may use the LST shocks for now and worry about other options later if needed. They still look tthe coolest on there anyway, and do work well.

BTW: The pillowballs are M6 thread. One option may be to talk to FLM to see if they can make a extra extended version of their alu savage upper arms w/ a M6 thread. But, I've seen him request minimum orders on some types of custom work, so who knows if that would work. Sounds expensive anyway, want to stay away from alu arms, and would like something easily replacible if it breaks anyway. I may just use a take a ballend from a 'uggy, remove the ball mount aprt, and just use the long tube end as a coupler between the M5 turnbuckle and the M6 pillowball intially just to get something working. May end up working well if I can find a section long enough to encase much of the turnbuckle. I still have my 0.5" nylon rod on backorder. I could use that too if the plastic proves strong enough. |

|

|

|

|

|

(#44)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

11.01.2010, 09:36 PM

So I'd been debating just how to go on a couple things, so I decided I'd order the body now and see how it looks and decide from there. Got it in today, and all I can say is, Wow... this thing is fraking huge!

I cut the tvps to match the wheelbase, but what I didn't know was just how wide it was going to be. I like it from most angles, but a couple others I'm not hot on... Pix:    The last is the one I don't like. Could be that its just the narrow width and lack of a wing and the back not cut out. Gonna have to find a way to make a good roll cage too to protect it. As huge as the sav looks extended, this body managed to make it look small lol! OTOH, I don't think I can shorten the tvps much as the body won't fit. 20" it is. Gotta get the width going to make it look right tho I think. |

|

|

|

|

|

(#45)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

11.01.2010, 10:02 PM

Here's a pic of an actual FG beetle. Looks like the ass end is just kinda big regardless.

What I did notice tho is that the inside of the tires on the FG are even with the edge of the body. They are tucked about an 1" in on the Sav. Hopefully getting the wider track and the body better mounted and painted will solve the dimension issues.  Been really busy, but what I aiming for now is getting another set of tvps cut with a few tweaks now I know the WB I want. I will focus on getting the TVPs done first. I did measure out what I need to cut out on the FLM bulkheads, and its going to be a bit of work, so that bit will come later. The truck will drive fine in the config it is now w/ the Sav arms, so no need to rush it. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode