|

|

|

(#121)

|

|

|

Destroyer of Tires

Offline

Posts: 626

Join Date: Feb 2009

|

02.18.2012, 08:56 PM

Good to see your still working on this, love how its turning out.

|

|

|

|

Weird looking |

|

|

(#122)

|

|

|

JERRY2KONE SUPERMAXX

Offline

Posts: 3,452

Join Date: Sep 2006

Location: HAYMARKET VIRGINIA

|

Weird looking -

02.19.2012, 05:47 AM

That channel is kind of weird looking. I think I would have tried to find some way to shape the chasis a little bit to reduce the flexing instead of adding more parts to the setup? That exta aluminum just looks a little bit ghetto to me. Maybe just a piec of althread would not look so over bearing. Just another view or idea. Don't get me wrong we have to find what work for us, but I think I would have found another way. R&D is always a series of trials and tribulations. It is good to see that you have not given up on this.

|

|

|

|

Do the U!!!!!! |

|

|

(#123)

|

|

|

working on a brushless for my wheelchair.....

Offline

Posts: 4,890

Join Date: Mar 2007

Location: minnesnowta

|

Do the U!!!!!! -

02.19.2012, 07:06 AM

Compared to a traditional r/c the u looks a little out of place, but for a custom build I love it!

There is plenty of strength there, a few random holes won't weaken anything, I say you cut holes to run wires and further cleanup the wiring. I like what you did with the motor wires.

It's "Dr. _paralyzed_" actually. Not like with a PhD, but Doctor like in Dr. Pepper. |

|

|

|

|

|

(#124)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,152

Join Date: Sep 2008

|

02.19.2012, 07:27 AM

I've seen angle used like that in a few cars. TBH it does look a bit ghetto but it adds so much rigidity. Nice work Brian.

I was thinking of getting some of these baja wheel extenders. I was thinking to use the fronts, lop off the 12mm axle and dill out the centre to suit the lst axle. Do you think this would work? |

|

|

|

|

|

(#125)

|

||

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

02.19.2012, 07:52 AM

Quote:

|

|

|

|

|

|

|

(#126)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,152

Join Date: Sep 2008

|

02.19.2012, 07:58 AM

It occurred to me that I could use a sleeve but it would need to be a snug fit to reduce slop.

|

|

|

|

|

|

(#127)

|

||

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

02.19.2012, 08:40 AM

Quote:

But if you want the full extension of these pro-line adapters I'm using, they are a direct fit on an 8mm axle. I only have to add an insert to them when I make them shorter: http://www.ebay.com/itm/Pro-Line-23m...item2318c5e810 |

|

|

|

|

|

|

(#128)

|

||

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

02.19.2012, 08:49 AM

Quote:

I actually put a lot of thought into bracing this - as it is a long truck and I chose to use a flat chassis for this build - for the ease of layout. I don't have a mill, nor will I use any machine-shop services for this build, so changing the chassis was not an option. I thought of different ways to bracing the length of the truck. Smaller braces front and back (like on truggies) would not work because it is too long. I thought of doing something down the center on the principle of the ue razorback - but the design was becoming too complex with the center diff and too much material would be used, in my opinion. In the end, the simplest solution seemed best - a top plate, which is all I have here. I couldn't use a flat top plate unless I attached it to the chassis at many points along its length - which I didn't really want to do. Finally, the u-channel is incredibly simple - just attach front and back - and has the extra usefulness of a place to route wiring. I'm still open to buying some different size u-channel (I looked at 1" x 1/8" with 1/2" legs - so lower profile) but this is what I had on hand and decided to try it out. I don't think it looks bad, and in the end, I am going to put a body on it, so we'll see - maybe I'll stick with this and maybe I'll try something else. |

|

|

|

|

|

|

(#129)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,152

Join Date: Sep 2008

|

02.19.2012, 09:00 AM

Quote:

The price of those prolines is pretty hard to go past

|

|

|

|

|

|

|

(#131)

|

||

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

02.19.2012, 01:05 PM

Quote:

|

|

|

|

|

|

|

(#132)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

02.20.2012, 02:47 PM

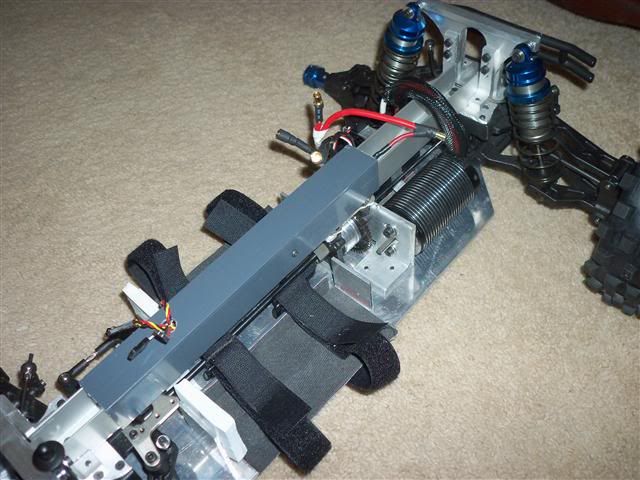

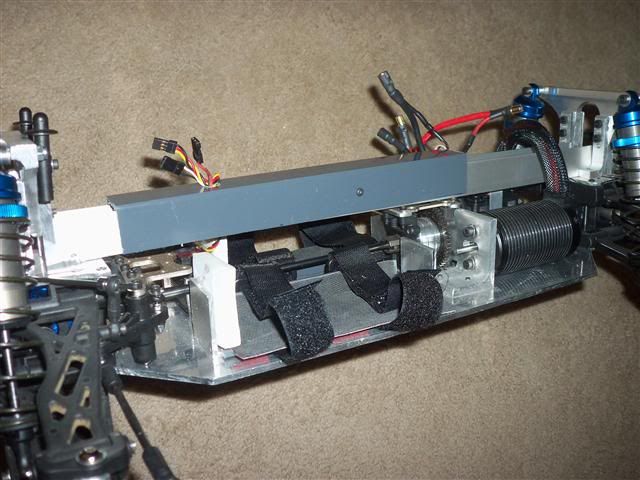

I had some pvc channel that fit over my al channel perfectly - so decided to use it for a cover and contain my wiring and bec underneath:

The receiver will mount on top of the pvc in front by the hole with the wires coming out ready to plug in. |

|

|

|

|

|

(#133)

|

|

|

Destroyer of Tires

Offline

Posts: 626

Join Date: Feb 2009

|

02.20.2012, 04:40 PM

Caving in to peer pressure? Just playin, the pvc does make a nice cover and finishes it off. Function over Form, but there's nothing wrong with dressing things up a bit at times.

|

|

|

|

|

|

(#134)

|

||

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

02.20.2012, 05:14 PM

Quote:

Anyway, for those of you who want to incorporate this unique design feature into your next custom build, I used: 1"x1"x1"x1/16" aluminum u-channel from McMaster-Carr pvc u-channel from smallparts.com (but order from amazon for free super-saver shipping). I cut the pvc legs down to 1.125" for a perfect fit. |

|

|

|

|

|

|

(#135)

|

||

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

02.23.2012, 08:29 PM

And for those of you wondering, the reason I switched to a black 1717 is this:

Quote:

|

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode