|

XTM xlb 1/7 scale buggy build |

|

|

(#1)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 129

Join Date: Jul 2011

|

XTM xlb 1/7 scale buggy build -

04.03.2013, 11:42 AM

I recently picked up a XTM XLB 1/7th scale buggy on a whim, I got a really good deal on it and it came with a two bags full of extras and spares. I soon started tearing into stuff and trying to find out about the weaknesses of the buggy. My plans are to make it brushless with a MMMv3, Castle 1520 1600KV and 6s lipos. I already have my electronics set aside, but waiting for other bits and pieces before that part.

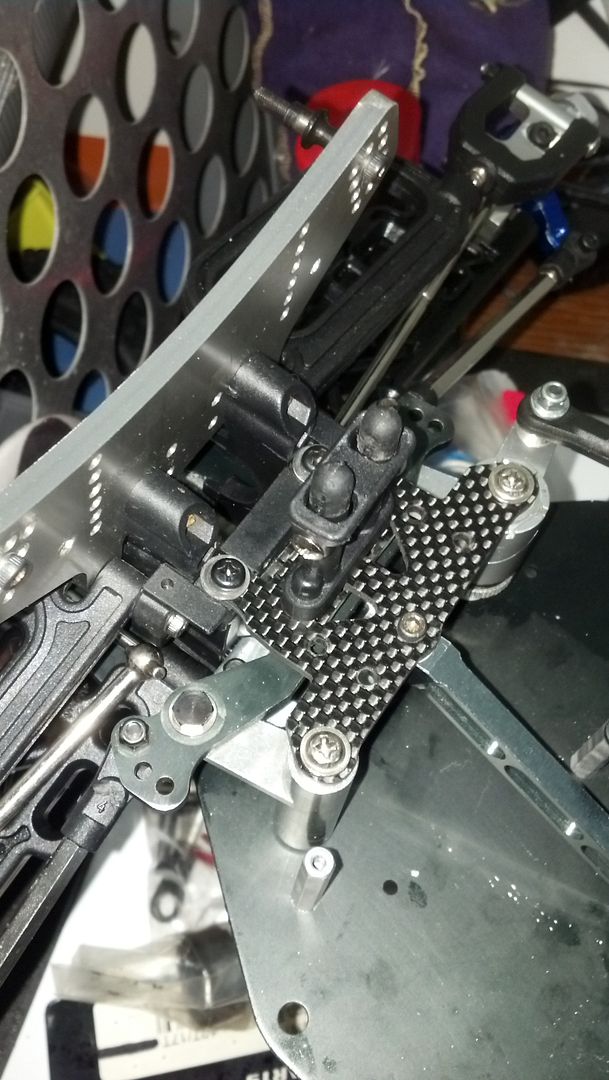

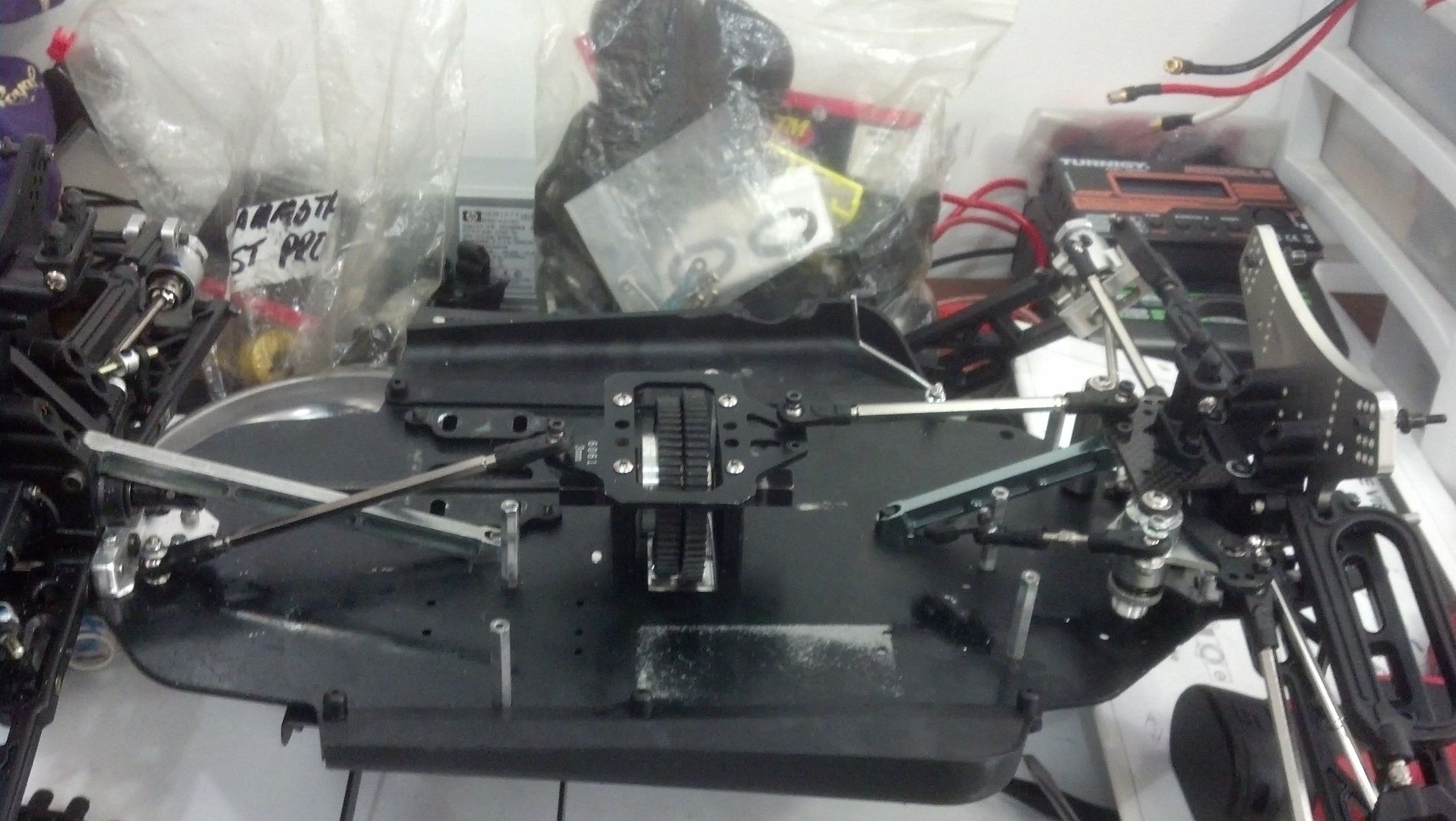

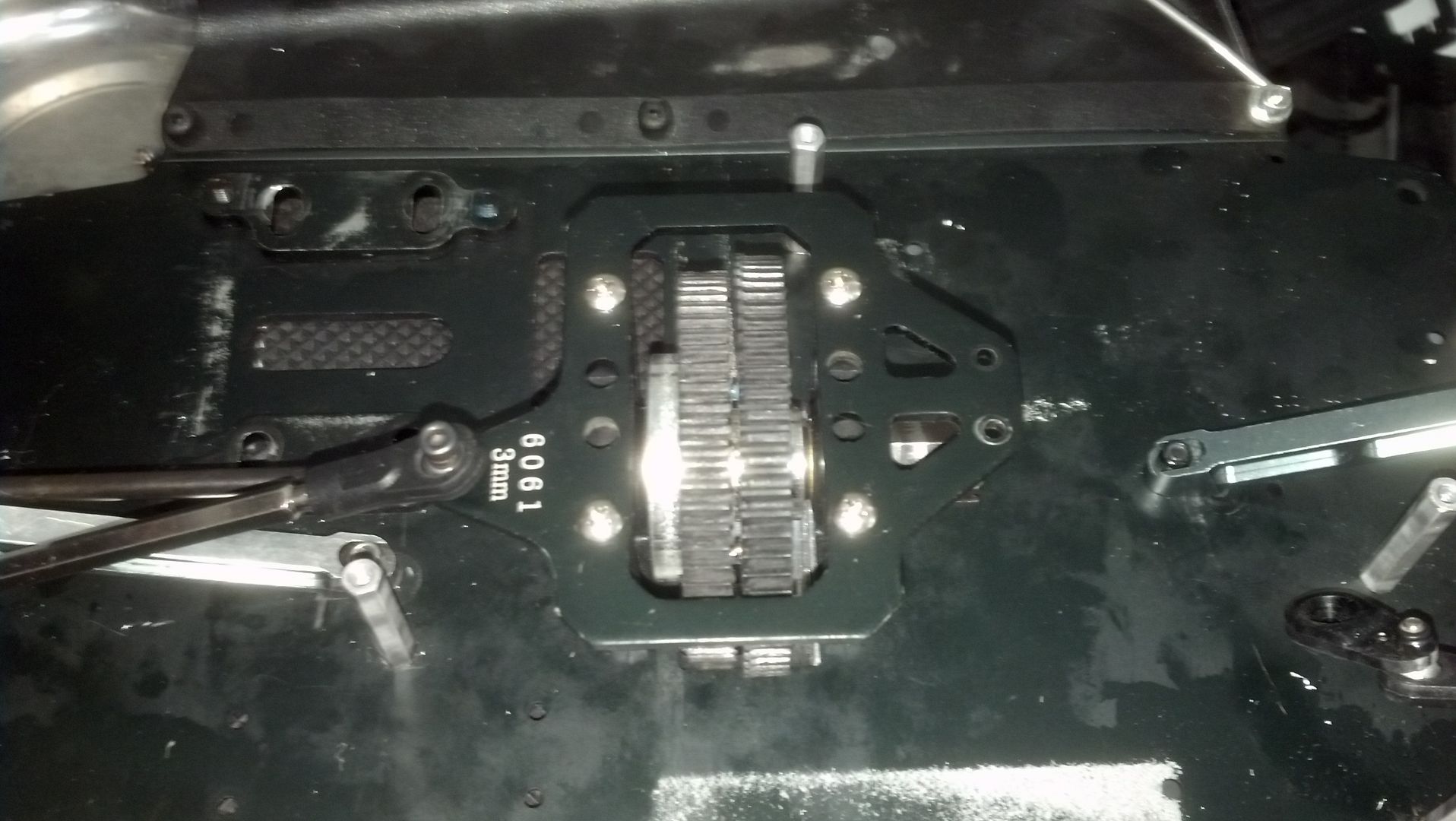

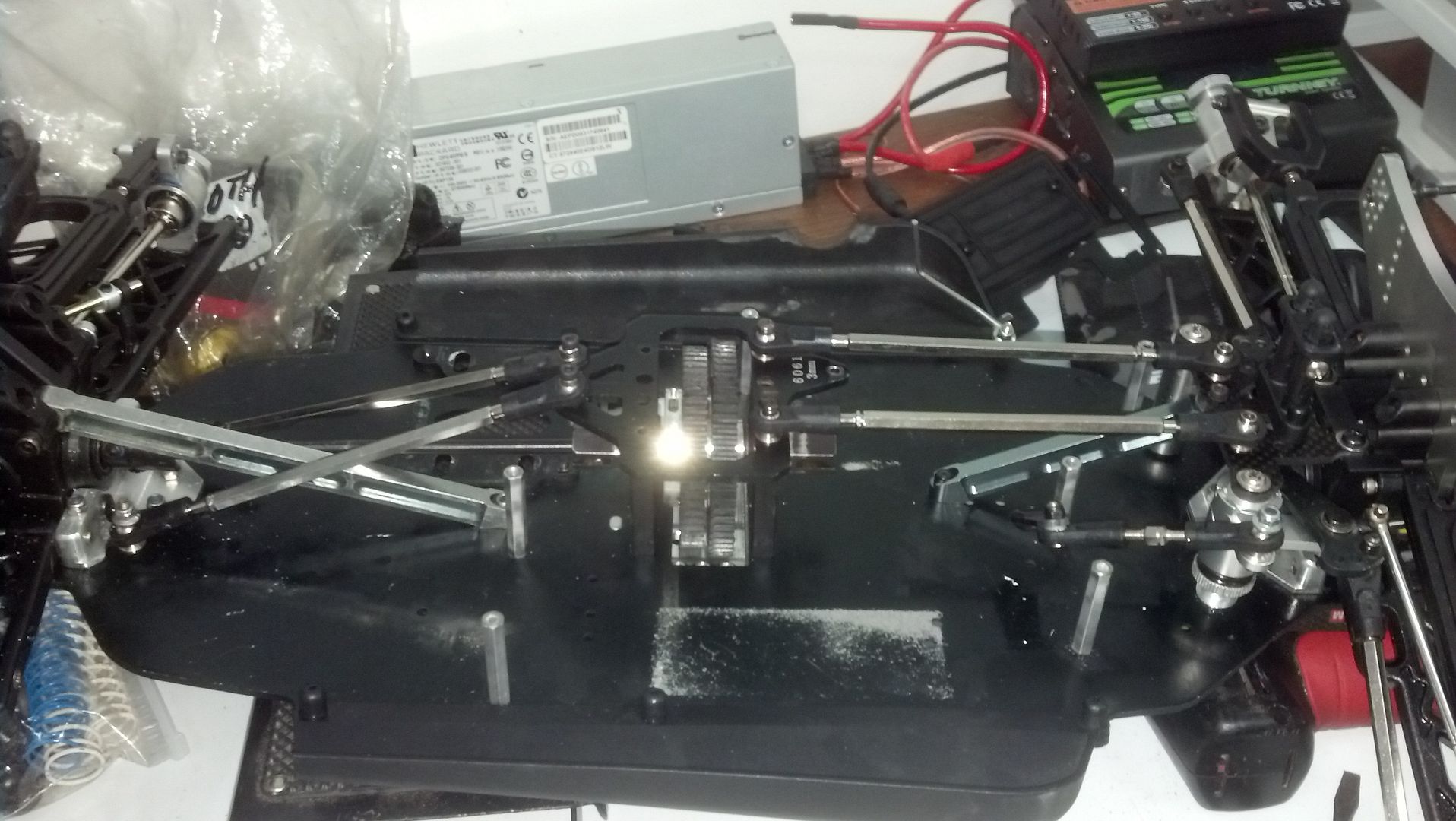

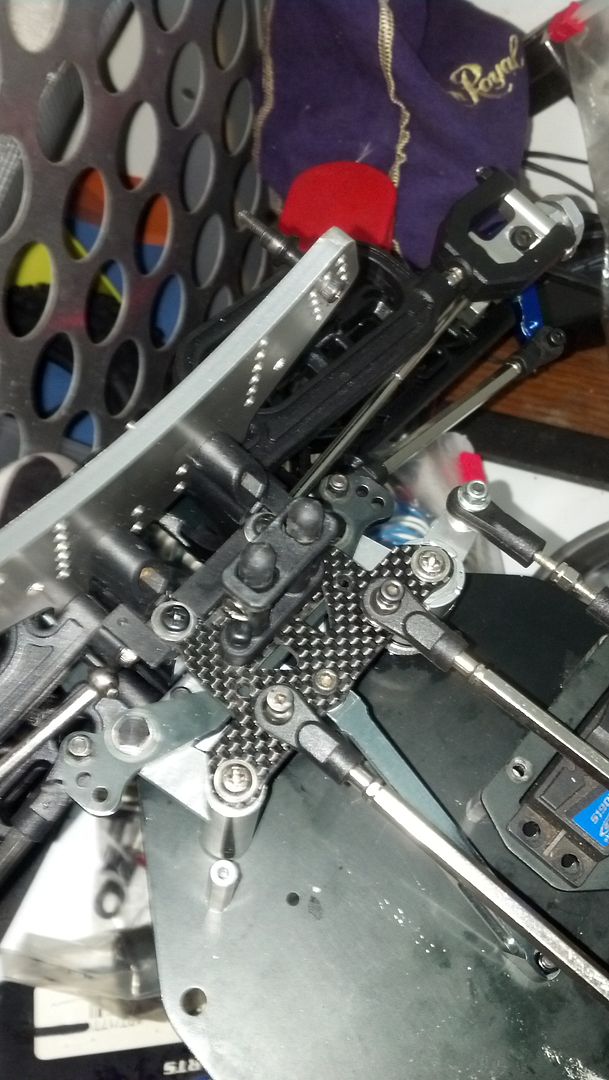

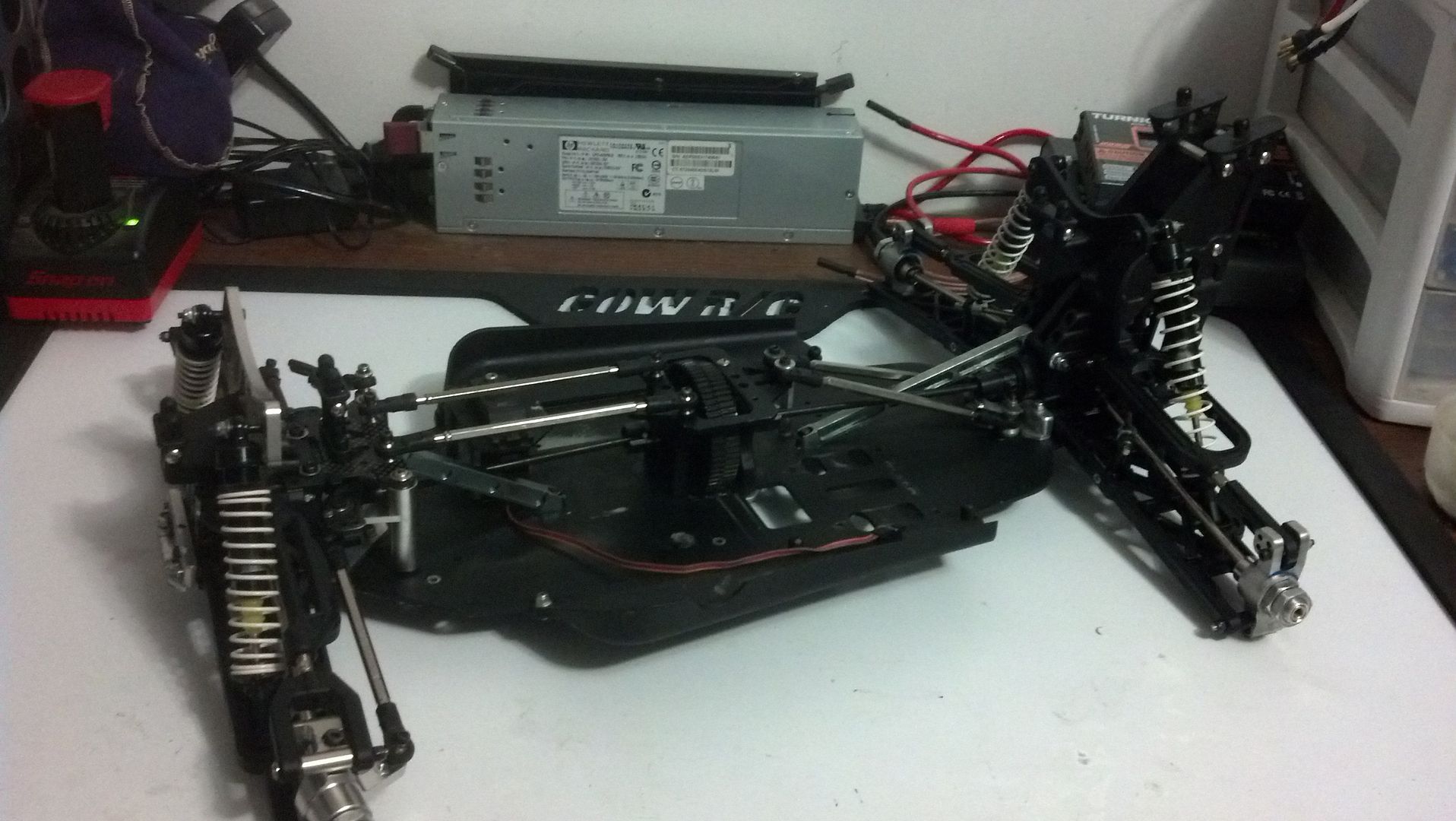

I learned the chassis is prone to flexing, This is the 1st thing I'm addressing! second, XTM used planetary style diffs apposed to the spider gear style and the stock 2 speed puts a lot of stress on the diffs because its essentially direct drive. I started off by digging through my box of Mugen MBX5T and MBX5R spares and came up with some interesting tid-bits... The mugen steering top plate was almost the same dimensions, So after some dremeling and drilling the m3 holes to m4 sized screws. It normally uses holes in the top plate to mount the front body post, The mugen on i had already had holes milled in it so i took a scrap piece of CF and made a plate to sandwich underneath the body post. Works great!    After i got all the steering sorted out, i went after the chassis bracing. It normally uses a set of turnbuckles and rod ends, but i already knew that this wasnt going to be strong enough. I Dug through my box of xlb spares and my mugen box again and came up with this;     A little more dremeling and a 2 more countersunk holes in the chassis and i was able to mount a set of MBX5T chassis braces pretty easily. Took me about 45 mins of thinking, dremeling, drilling to get it all situated. But i was still a little leery of the chassis flex, I know you dont want a stiff, hard as a rock chassis, you do want some flex for traction. But it was still a little to much to my liking. I then came up with this idea...The diff top plate has a mounting hole in the rear for the rear brace and 2 in the front...so i flipped the plate around!    This is where I'm at so far, I still have to take off the rear hinge pin retainer and modify it for a second rear brace and drill the chassis. I feel it's come out pretty good so far! Sorry bout the pictures, they aren't the best. Took them in the heat of the moment with my phone because it was already sitting there. Anyone has any feedback let me know! I'm also looking for a set of LST2 threaded shock bodied shocks! |

|

|

|

|

|

(#2)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 129

Join Date: Jul 2011

|

04.03.2013, 11:42 AM

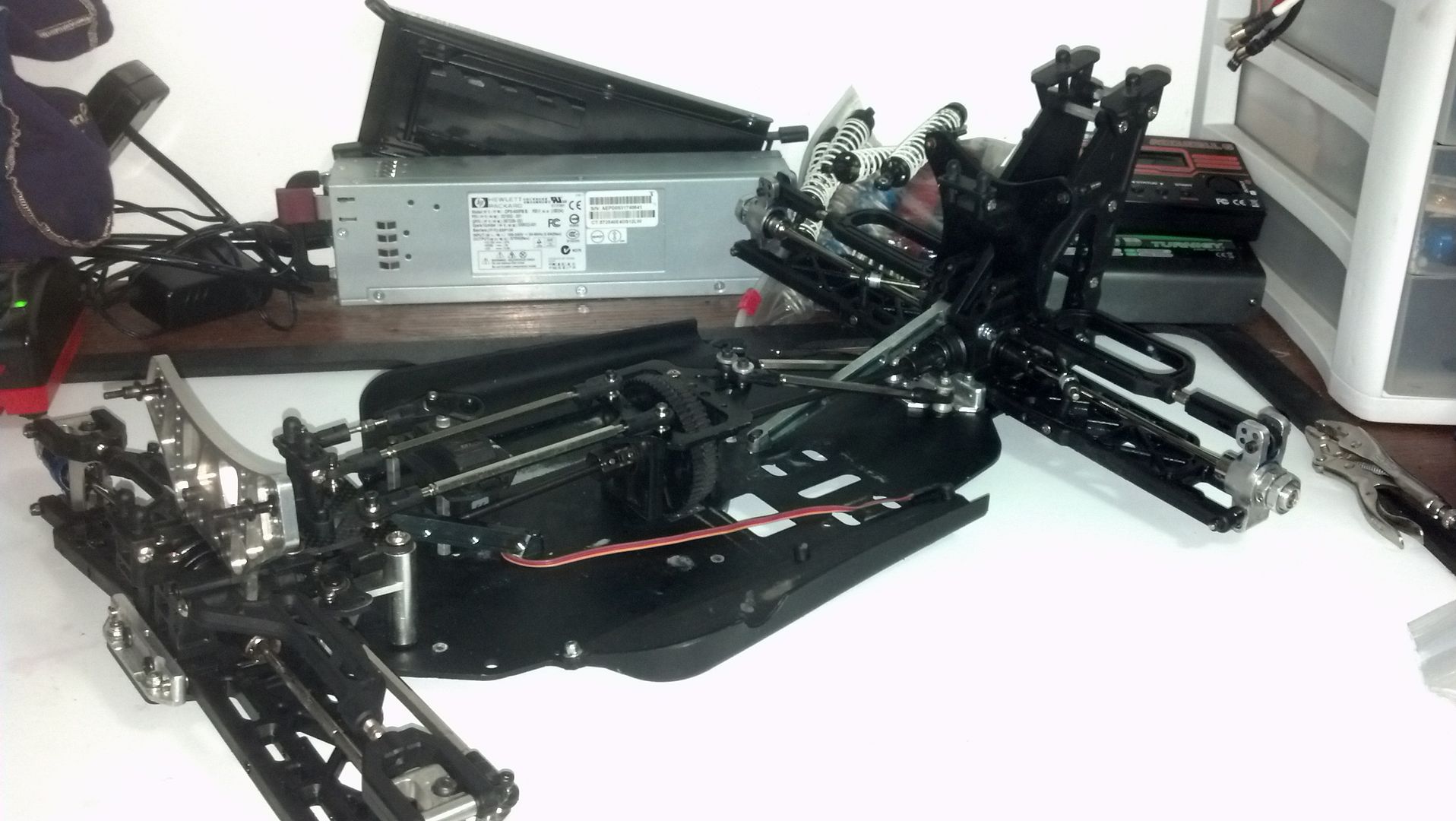

Spent a little more time on the XLB last night. Swapped out the XLB Upper a-arms for some XTM mammoth ST arms. This will allow me to run LST2 sized shocks :sneaky: I also had the front diff out because it was leaking, rebuilt the diff, shimmed and greased it up. I hopefully have a line on some newer style spider geared diffs that should work.

sense the shocks where leaking all over the place when i received it, i decided sense i don't have LST2 shocks yet, i will rebuild the stock ones to at least have something on it for now. Luckily i only rebuilt one shock and figured out that there was at least 3 different sized shocks in the bag. After that one I looked in the manual and fount the 4 correct length ones i was supposed to be using! Ended up using 50W losi oil because it was the thickest i had, manual shows 100w! also the manual states 30k-100k for the diffs!   Now here she sits, I'm waiting on a plastic diff mount from a XTM XT2E to see if it has the same goofy spacing as the XLB, It was a $3 part and it was cheaper than buying the aluminum motor mount and finding it didn't work.

|

|

|

|

|

|

(#3)

|

|

|

working on a brushless for my wheelchair.....

Offline

Posts: 4,890

Join Date: Mar 2007

Location: minnesnowta

|

04.04.2013, 04:12 AM

Is there any way to ditch the 2 speed?

Looks like it will be a fun car!

It's "Dr. _paralyzed_" actually. Not like with a PhD, but Doctor like in Dr. Pepper. |

|

|

|

|

|

(#4)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,152

Join Date: Sep 2008

|

04.04.2013, 07:31 AM

Very cool! Love the work you're doing on it. The bitsa builds are right up my ally. I have some spare lst shocks but I don't think you would like the shipping from Oz.

That's some heavy oils all round. Be watching

|

|

|

|

|

|

(#5)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 129

Join Date: Jul 2011

|

04.04.2013, 10:18 AM

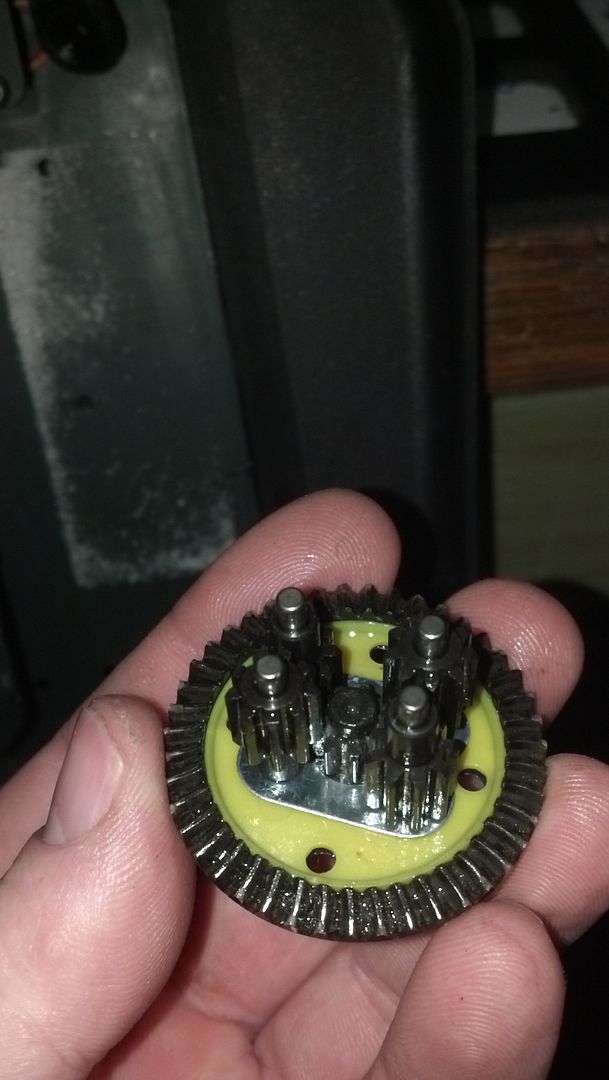

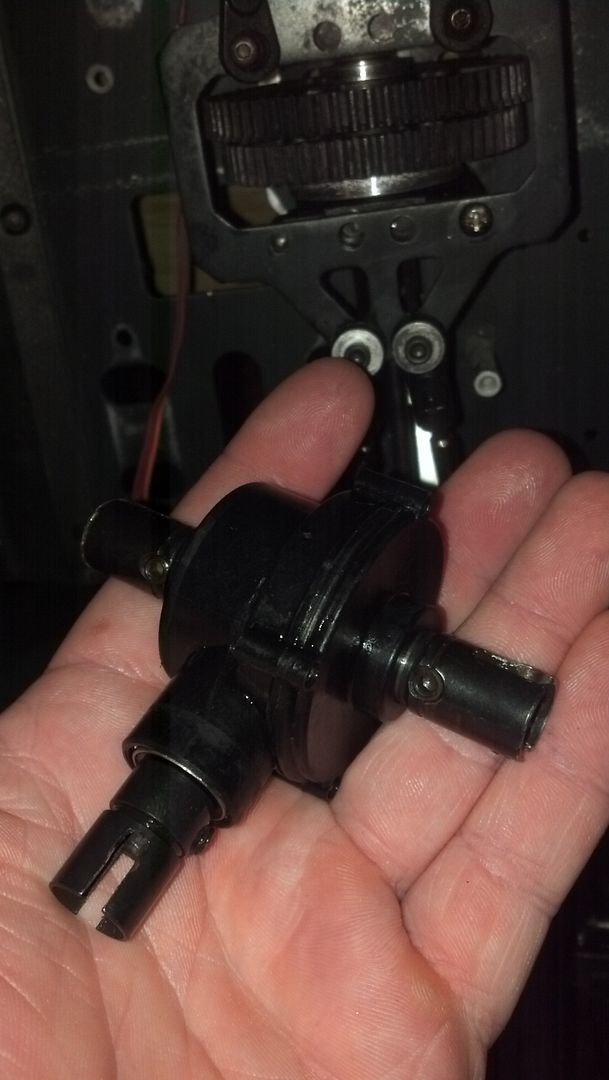

Xtm did make a center diff upgrade but with a goofy 63t spur gear and planetary gears inside instead of spider gears. I have one, but the spur has been stripped and finding one is close to impossible.

I've been doing a lot of research and cross referencing and I think I'll be able to use spider Diffs out of the newer xtm xt2e. I have only found one report of the xt2e center diff and motor mount working on the xlb and all that was said was it works with a little modification.... |

|

|

|

|

|

(#6)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 129

Join Date: Jul 2011

|

04.04.2013, 10:20 PM

So i measured the XTM xlb center diff and bearing to bearing it is 35mm, My spare mugen center diff is 32mm. If anyone has a extra center diff measure i'd greatly appreciate it. I cant find any specs on a XTM xt2e center diff yet.

|

|

|

|

|

|

(#7)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 129

Join Date: Jul 2011

|

04.11.2013, 09:29 PM

This kinda got put on the back burner right now as i have gotten busy with changing career's. But the xt2 mount did come in and is not going to work

I emailed mike about getting one made as he made one for a member previously. I Think i found that a OFNA jammin X1 center diff should work inplace of the XTM 2spd setup |

|

|

|

|

|

(#8)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 129

Join Date: Jul 2011

|

04.14.2013, 08:36 PM

Well some good news, my buddy came over to the west side of the mountains for the weekend to visit and had brought some of his rc gear over. Just before him leaving we spotted a kyosho diff from his e-mbx5T conversion that had bad internal bevel gears. Lo and behold its 35mm bearing to bearing!

So I'm gonna order new gears and a 52t spur gear and then I'll be moving on to the next step! I wish Mike would get back to me on a mount, I really don't want to have to fab up a tekno mount.

|

|

|

|

|

|

(#9)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,402

Join Date: Aug 2008

Location: Twin Citys Mn

|

05.16.2013, 09:04 PM

we put lst diffs in a buddys xlb, the held up, the stock xlb diffs failed pretty fast on 5cell

|

|

|

|

|

|

(#10)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 129

Join Date: Jul 2011

|

05.16.2013, 09:50 PM

I found a Kyosho center diff that will work and I mailed the diff/mount and related parts to Mike to have him make me a motor mount. Hopefully he has some spare time to whip one out for me.

Where the LST diff's drop in or was there some modification needed? I know the stock xlb diff's with the planetary setup aren't very good, but i hear good things about using the XLT2 spider style as an upgrade. I'd like to hear more about the lst diffs though! |

|

|

|

|

|

(#11)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,402

Join Date: Aug 2008

Location: Twin Citys Mn

|

05.18.2013, 12:07 AM

it wasnt drop in, but it wasnt to crazy to fit them in if i remember right

|

|

|

|

|

|

(#12)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 129

Join Date: Jul 2011

|

07.01.2013, 07:10 PM

Still waiting on my diff mount from mike...been a long drawn out process so far. At least waiting has paid off a little, I was able get 6 losi xxl shocks to continue on with the conversion! I didn't even realize how huge these shocks actually are! Now to figure out how I'm gonna get them on lol. Pardon my messy work area, I just brought my MGT in and plopped it on the desk

|

|

|

|

|

|

(#13)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

07.01.2013, 10:32 PM

Nothing like a lst shock. Makes the rest look like they are missing some parts!!!

Cool build, I will be watching! |

|

|

|

|

|

(#14)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 129

Join Date: Jul 2011

|

07.01.2013, 10:40 PM

Haha yeah! I've never seen one first hand before, only pictures and my first reaction was "Holy F%&# these are huge!" I still need to get some lst shock standoffs and I was hoping i dont have to buy full tower setups off of Ebay sense i dont need the rest, but it looks like it might go that way

Linc i'll be using the 40 series crimefighters from you on this bad oscar once its all done

|

|

|

|

|

|

(#15)

|

|

|

RC-Monster Mod

Offline

Posts: 6,597

Join Date: Apr 2007

Location: NJ

|

07.02.2013, 08:49 AM

Don't know what it was - I tried them in my XL Savage and just kept snapping shafts but they are huge and looked great

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode