|

|

|

(#106)

|

||

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

08.05.2010, 03:37 PM

Quote:

I think these are great springs - they really allow me to adjust the front of my truck from stiff to soft, and I've needed that to dial in the best handling setup for different types of driving (jumping vs. flat speed). Now, get back to rebuilding your shocks

|

|

|

|

|

|

|

(#107)

|

||

|

Muggy love

Offline

Posts: 285

Join Date: Apr 2009

Location: Slovenia

|

08.05.2010, 03:51 PM

Actually I only rebuilt one since the TiNi shaft snapped. And all the springs are already in the same order lol.

Never let a girl pick up the remote on 50% EPA!  EDIT Quote:

|

|

|

|

|

|

|

(#109)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

08.05.2010, 04:01 PM

Ok, I got my Al spindles today and added a bearing to each so they're ready to install when I get time. The inside diameter of the spindle where I want the bearing was about 15.85mm. So a little sanding with a mini-dremel sanding drum and they pressed right in for a snug fit.

Here's where the bearings are normally:  Here's where the third one is:  Inside view:  The reason I did this is that one of my 15x21 skinny bearings blew out a while back and I wanted to try to give it a little help. I don't know how much this will help, but it was easy enough to do. For the rear carriers, I have an 18mm od, 16mm id Aluminum sleeve that I'll use to install an extra bearing. |

|

|

|

|

|

(#110)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

08.06.2010, 05:27 AM

thats a great design! 3 bearings to take the load on each axle! But how do the shafts sit in the axle? i cant see how that would work? can you post a picture from another angle

|

|

|

|

|

|

(#112)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

08.06.2010, 05:50 AM

thanks buddy... i wish they did shafts and axles like that for the savage

|

|

|

|

|

|

(#113)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

08.15.2010, 08:29 PM

OK, back from a week's vacation and a little time to work on this now.

Here's what I plan to do with the 70mm m4 bolts through the bulkheads. I have holes drilled up through the bulkheads for the bolts like this:  at an angle so they clear the shock tower:  Now I need to make an aluminum top plate and a skid plate for below the chassis to shield the cap head bolts sticking out. I'm using the regular holes in the chassis for these four bolts. The m4 screws I have in the bulkheads now are doing the job, but get knocked loose from impacts - there's a lot of shear force on them with this 19lb truck. I imagine each time they get knocked loose and retightened, the plastic that's holding them is degrading (one of the eight is stripped now). I'm hoping that this is holds up much longer.

|

|

|

|

|

|

(#114)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

08.17.2010, 12:46 PM

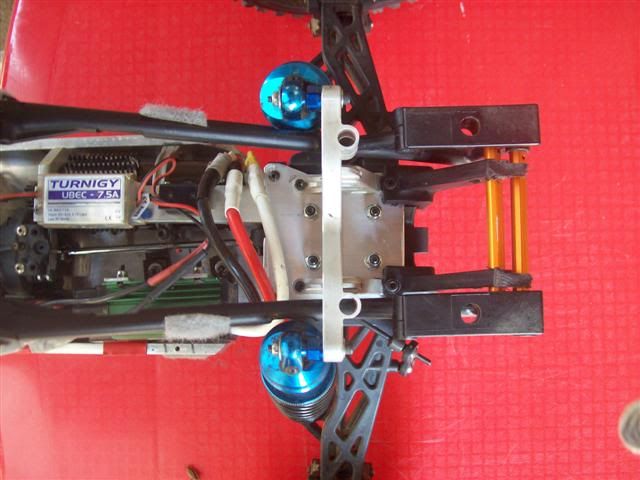

I rebuilt the rear end today with the bulkheads and m4 bolts shown in my previous post.

The shock tower is now screwed into the 1/8" Al top plate I made with m3 screws - so I'm not relying on any screws into plastic to hold things together. We'll see how it holds up. |

|

|

|

|

|

(#115)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

08.18.2010, 01:57 PM

I did some jumping with this today and had a few bad tumbles (the worst its had other than my soccer goal incident) and no breakages to report! My recent mods are holding up well so far.

|

|

|

|

|

|

(#116)

|

|

|

RC-Monster Stock

Offline

Posts: 36

Join Date: Jul 2010

|

08.18.2010, 03:35 PM

good to hear sir! nice project also

Danny |

|

|

|

|

|

(#117)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

08.28.2010, 11:10 AM

Thank you.

Here's my other (little) summer project. I love driving 1/8 buggies but don't really like the normal buggy body. So I had a Sportwerks Mayhem roller to convert and decided on this:  It's the Revo 2.5 Pro-line Baja bug body. Painted with pactra Lime Ice (RC303) rattle can backed with pactra backing black (RC304). RCM motor mount, powered by MMM with Neu 1512 3d on 4s. |

|

|

|

Winter maintenance/rebuild |

|

|

(#118)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

Winter maintenance/rebuild -

01.12.2011, 08:44 PM

Alright, I got this big thing out and started tearing it down to clean and rebuild. I haven't had much time to drive it since summer but am looking forward to getting it out again when the weather turns nice.

I took the front end off and started with the front diff. I checked the titanium nitride gears and saw some wear:   These gears will be replaced with new ones. I'm happy that they have held up so well to 8s-10s power on a 19lb buggy. I'll see if I can shim them any better this time around, but if the next set gets me through a season of bashing like these did, I'll again be happy. I also checked my home-made extended front center driveshaft, and it looks great - not twisting, bending, etc:  If I have time this winter, I'll make a spare, but this one will go back in for now. More updates to follow as I have time to tear down and rebuild. |

|

|

|

|

|

(#119)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

01.16.2011, 04:32 PM

I'm still rebuilding the front end. Today I rebuilt the shocks. I did something that mistercrash suggested when he was building his XXL - I put a thin lexan piece on the shock piston covering 10 of the 24 holes (imitating the traxxas variable damping kit). I've found I need to adjust the front shock pre-load a lot depending on whether I'm jumping (harder) or doing speed runs (softer) to get good handling. I'm hoping this mod will minimize the amount of adjusting I need to do - it should me good damping and good rebound. I used lighter oil (20wt) and I like the way it feels. We'll see:

Here is the front end partially rebuilt:  I bought new Al front bulkheads in a lot of parts some time back - so I'm going with them on the front. I have my "through-bolts" on the back holding everything together and will probably stick with them. My homemade Al shock mounts on the front have done well and have only slightly bent one of the screws holding them. There was some questions raised earlier in this thread about whether the screws would hold up - so I'm happy to report that they have. |

|

|

|

|

|

(#120)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

01.16.2011, 09:01 PM

By the lookd of the gear the pinion needs to be shimmed closer to the diff, and the diff needs to be shimmed so it pushes against the pinion more. When I build diffs I like them to feel a little "tight" they way they will wear in and not be slack. Just did a hpi bulletproof set in a gh savage bulk and they do feel a bit tight in places when you rotate them. I also use synthetic grease on those gears. Given the vay lst diffs are sealed, some gear oil or oil stabilizer could be used for lubrication. Keeping a thin layer of oil on the gears will cut down wear and drag alot. I wish the savage gears were sealed in a case like the lst...

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode