|

Direct to diff outrunner conversion*update* |

|

|

(#1)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

Direct to diff outrunner conversion*update* -

09.25.2007, 12:02 AM

Copied this from the temp forum. Got bored recently and tried 4s lipo. The truck worked alot better, slight cogging from a standstill, but if I was liberal with the throttle it would take off without problems.

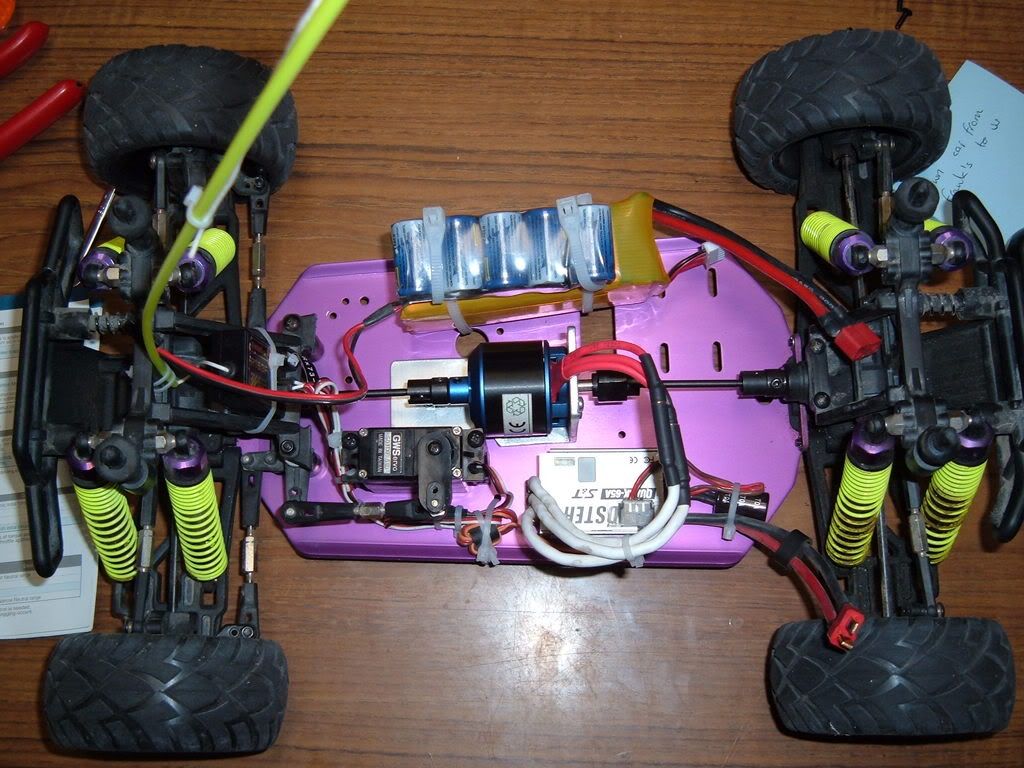

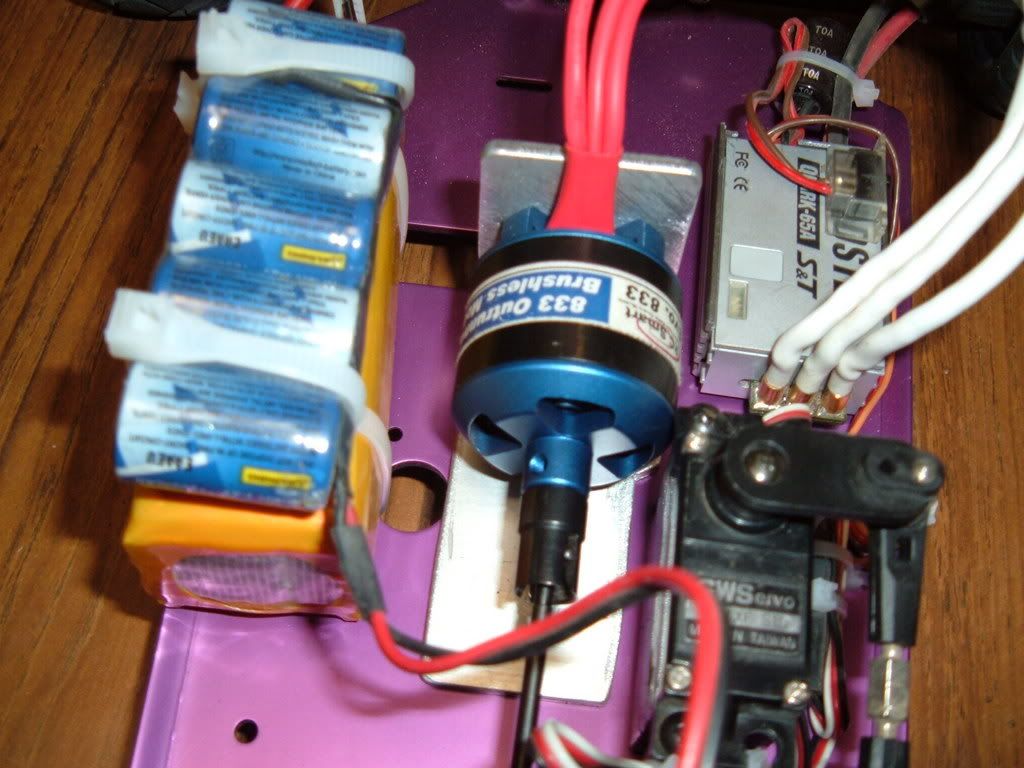

Here is a link to the thread: http://www.rc-monster.com/tempforum/...read.php?t=845 Here is the original post: Hey guys, just finished my mutant redcat/outrunner truck thingy. It runs great, still playing with the quark settings to get zero cogging from a standstill. I almost have it right. Truck runs well, temps after 10mins were 150 motor, 130 esc and 100 battery. I am running a 5s 2200mah 20c battery. Interestingly enough setting the quark for outrunner does not work as well as the std inrunner setting. I have the torque settings all the way up and the neutral set wide, as the maunual suggests that for cogg prevention. Differential Ratio: 2.75 Transmission Ratio: 1 Other Ratio: 1 Spur Tooth Count: 1 Pinion Tooth Count: 1 Total Voltage: 18.5 Motor KV: 833 Tire Diameter (inches): 3 Tire Ballooning (inches): 0 Motor Current Draw: 0 Motor coil Ω: 0 Spur/Pinion Ratio: 1 : 1 Total Ratio: 2.75 : 1 Tire Circumference (inches): 10.21 inches (259.34mm) Total Motor Speed: 15410.5 RPM Vehicle Speed: 54.18 MPH (87.03km/h) Effective Speed Rate: 2.93mph/V (4.7kmh/V) Effective KV Value: 833 Motor Torque: Amperage not specified... Final Torque: Amperage not specified... Heres the pics, enjoy. Please excuse the zipties

|

|

|

|

|

|

(#3)

|

|

|

Z-Pinch racer

Offline

Posts: 3,141

Join Date: Nov 2006

Location: SK, Canada

|

09.25.2007, 04:51 PM

That looks great! I am going to try my direct wheel drive outrunner setup some day... wouldn't that be quiet!

Which motor are you using BTW? Have you considered the new Eflite Power xx series motors? They are supposed to be one of the best outrunners available, from what I hear. Vids?

|

|

|

|

|

|

(#5)

|

|

|

Guest

Posts: n/a

|

09.25.2007, 05:45 PM

We did a direct to diff conversion on a Kyosho Inferno GT with a Neu 1512 1900kv motor. On 5S with 3.9" GRP Rally tires, we clocked it in excess of 90 mph several times.

What is the kv rating of the motor that you are using there? |

|

|

|

|

|

(#6)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

09.25.2007, 06:29 PM

Motor is a 833kv outrunner, got it cheap off ebay.

Not too familiar with the power output of the various sized outrunners. I would do a lower kv next time, 650kv sounds about right. I would also go bigger, like a 45mm can that is longer, so more torque. This setup has plenty of power, but the truck is very light, so that helps. This is not suited to off road IMO, it works great on road, very smooth with the quark and less drivetrain resistance than with a pinion/spur. Seems to be effecient too, not enough testing yet to be sure though. |

|

|

|

|

|

(#7)

|

|

|

Yip Yip Yip...

Offline

Posts: 1,489

Join Date: Aug 2007

Location: Australia

|

09.25.2007, 07:13 PM

That is nice. It should be really efficient. Less weight and less resistance. A bigger can would help. More power and may be better off road performance (?).

|

|

|

|

(#8)

|

|

|

Z-Pinch racer

Offline

Posts: 3,141

Join Date: Nov 2006

Location: SK, Canada

|

09.25.2007, 07:31 PM

http://www.greathobbies.com/producti...d_id=EFLM4060A

OR http://www.greathobbies.com/producti...d_id=EFLM4046A Those are 50mm cans, and the Power 60 does 1200 watts continuous. It weights the same as an XL motor. 380 grams You can also take the shaft out, and make a custom one, or whatever. |

|

|

|

|

|

(#9)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

09.25.2007, 09:34 PM

Quote:

The 46 size 670 kv looks interesting, The lower kv would let me put larger tires back on it and have more torque for startup. Do you think that the quark 65 would be ablee to handle that motor? Plus I would need to step up to better batteries, I have a pair of 20c 5000 2s lipos to run. And my motor mount would have to be remade to accomodate the larger can size. I will see about finding one of these motors and change up my setup. |

|

|

|

|

|

|

(#10)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 149

Join Date: Dec 2005

|

09.25.2007, 10:28 PM

if that is a 4 pole out runner, see if your esc has 30 degree timming, that should fix your cogging issue

|

|

|

|

|

|

(#11)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

09.25.2007, 10:42 PM

Not sure if the quark has that kind of adjustability, I will check.

Probably need to do the heatsink mod the the 65 as it appears to be comming of the thermal tape. Any reason why I can't delete the case entirely and just epaoxy a heatsink to the fets and maybe put it in a little box like the MM? Or maybe shrink it like a bk esc? |

|

|

|

|

|

(#12)

|

||

|

Z-Pinch racer

Offline

Posts: 3,141

Join Date: Nov 2006

Location: SK, Canada

|

09.25.2007, 10:57 PM

Quote:

I am not sure if the Quark 65 would handle it. What kind of speed would that get you with 670kv? That is what you need to know. Now I am curious about running one of these in my Revo... I am gonna go do some calcs. |

|

|

|

|

|

|

(#13)

|

|

|

Z-Pinch racer

Offline

Posts: 3,141

Join Date: Nov 2006

Location: SK, Canada

|

09.25.2007, 10:58 PM

Outrunners are usually 12 pole designs, otherwise, there would be no point to using them in place of inrunner (low pole motors).

|

|

|

|

|

|

(#14)

|

|

|

Z-Pinch racer

Offline

Posts: 3,141

Join Date: Nov 2006

Location: SK, Canada

|

09.25.2007, 11:14 PM

Okay, a Power 60 motor (400kv) on 5s2p A123, or better yet 4s lipo (lower top speed) should be just about right for a maxx or Revo truck.

Top speed would be around 48mph with 5s2p A123, or 45mph on 4s lipo. OR, on the extreme torque end... the Power 110 (295kv) on 5s lipo or 6s2p A123 for a little over 45mph, and crazy, crazy torque... that would be a silent, deadly machine.

|

|

|

|

|

|

(#15)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

09.25.2007, 11:23 PM

Yeah, my setup with the 46 on 4s lipo would be around 40mph. My only issue would be lack of a slipper for an off road vehicle, and you would need a good slolid motor mount, like 1/4" 7075 al. I was also thinking that i could incorporate two revo slippers, one on each end of the motor. a custom shaft and adapters to replace the spurs with drive cups would be required. Might add too much length though. If you really want one, I may be able to get a discount, not sure how much but give me the #s you want and I can ask my buddy. Looks like the 46 would be about 80-85 bucks from him.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode