|

|

|

(#46)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

12.27.2007, 05:20 PM

Putting the pinion on the very end of the motor shaft is bound to cause alot of stress on the shaft, especially if the truck is doing jumps and bouncing around. It would in all likelyhood snap, but that is down to the fact it is only 1/8", the common size used when it was designed. Hopefully the 5mm shaft upgrade will allow the pinion to be place further towrds the end of the shaft without risk of damage. Still, Traxxas were aware of this, yet said nothing- now there are a lot of people with motors that are no good for the new truck; you have to have a little sympathy for them and understand their predicament. I think a clever person with a CNC will need to design a new motor plate that is recessed in certain areas to allow the motor to be mounted further forward & line up with the spur better.....

|

|

|

|

|

|

(#47)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

12.27.2007, 05:24 PM

Good information there Linc on your motor comparisons. I like to see side by side data like that.

On the "wrong or right" angle of looking at this, Traxxas makes alot of great products. This is their design, and afterall, they can build them however they want to. That's their right to do so. In my postings, I don't intend to be "hard" on anyone. I'm merely looking at the differences and what we have to do to make this work. I would like to see Traxxas come up with an answer to this. Since it's not a very likely thing for aftermarket manufacturers to change their already successful motor designs. The upside to all of this is a MUCH tougher built transmission AND a MUCH tougher slipper design that does promise a HUGE power Capacity. Those of us who play with designs and different builds, this just presents to us another challenge but with benefits.  I for one, love a good challenge.

|

|

|

|

|

|

(#48)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

12.27.2007, 06:11 PM

Yes challange is a good thing. If traxxas designed a spur gear like the pede/rustler design, that "cups" over the slipper it would cure the problem. My point is that a 4yr old design, that is really not that "new" anymore, is somehow more important than a brand new, desined for high power brushless, vehicle? I just have to wonder about some people. What is the point of the new emaxx, if they already had an old emaxx with the novak system in it, why buy a new vehicle? Does not make much sense to me? The only difference between the two at that point would be better steering and slightly longer wheeelbase! The upgraed drivetrain would not be necessary, cause they would already have a vehicle that works. Not to knock Novak, but the system needs upgrading and there are much better components available for the same price. I know that the novak is popular, but so were alot of other rc products that no one uses anymore, mainly due to new and better products taking their place.

|

|

|

|

|

|

(#49)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,803

Join Date: Aug 2005

Location: arkansas

|

12.28.2007, 01:27 AM

i guess it wouldnt matter except for i just realized they are talking about a 1/8 shaft instead of the 5mm like every other decent sized brushless motor uses.

|

|

|

|

|

|

(#50)

|

|

|

NeuMaxx

Offline

Posts: 1,286

Join Date: May 2007

Location: Near New Orleans

|

12.28.2007, 05:46 PM

Straight from the horse's mouth:

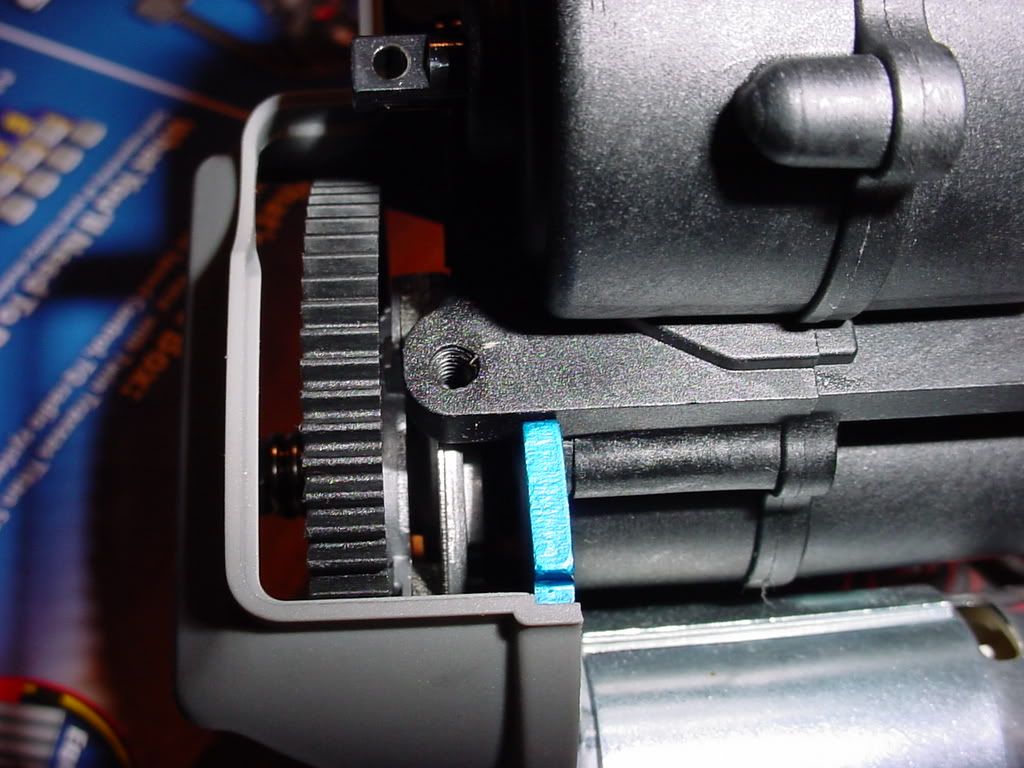

"OK guys, here is the story. The Novak system WILL bolt up and WILL work. You have to leave the pinion extended off the end of the shaft. The pinion should turn true and fit far enough onto the shaft to remain secure. The only issue revolves around the shaft of the Novak motor. Stock up on rotors, as you will probably break them if you run hard (they could even break on the old E-Maxx, this is not breaking news- no pun intended). We pictured the Novak system simply because it was the only true bolt in, readily available system on the market at the time. Hobbyists wil probably see these companies evolve to produce systems compatible with, and able to withstand the power necessary to propell the truck. -You cannot use a dished spur, it would interfere with the right transmission mount. -Post #57 has the best solution in this thread so far, or until Noval offers a 5mm shaft. However, two things to note: 1) It will need to be run without the gear cover (both upper and lower parts). 2) The motor plate is designed to provide additional support for the input shaft bearing on the trans case-this is a snug fit. Moving the plate may still work, but we cannot promise this as we only tested it as designed. Traxxas produces innovative new designs which tend to cause others to evolve. There is a short period of time following a new release that sometimes requires special procedures in order to achieve the desired results. As time goes on, hobbyists will see more and more readily available products to achieve those same results. Zinno a Traxxas employee |

|

|

|

|

|

(#51)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 125

Join Date: Sep 2007

|

12.28.2007, 10:53 PM

Hi my name is Doug I am paralyzed from the chest down with no hand function and limited arm control due to a bad dirt bike wreck last year.

I just have to say that I love this forum...1 year ago I baught my first Maxx and got into this hobby...The first few months I didnt know much but 3 Maxx's and a year later with the help of forums like this one... I know my Maxx inside and out, and was able to find a single stick transmitter and receiver that allows me to drive my trucks with the palm of my hand I just want to thank everyone who ever posted..without your EXP I wouldnt have a hobby at all  Ok sappy stuff to the side I have 2 old maxx's left and 1 new on the way...The shaft length is a problem but one that will be fixed in time...the v twin can be done at home with a simple Y harness from the receiver just like Kershaw Designs twin 970 set up if thats what you want (that special programming to run twin motors is just crap)...I myself want a 5mm shaft because I beat my trucks like (red headed step children) and the less down time this cripple has the better. any way thanks to all. |

|

|

|

|

|

(#52)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

12.28.2007, 11:02 PM

Hey Doug, glad that we can help you out, plus I am sure that your experience with rc will be handy to us as well. I have only been in this hobby 2 years, but the steep learning curve taught me quickly!

I undestand your desire to run a 5mm shaft, it just makes sense for hard bashing. |

|

|

|

|

|

(#53)

|

|

|

Knowing You're Hooked on RC: Priceless...

Offline

Posts: 271

Join Date: Feb 2006

Location: Blue Springs (KC) MO

|

12.28.2007, 11:03 PM

Is there a way to flip the motor around and mount it with the front of the motor facing backwards? They used to make conversions for the E-Maxx like that to move the mass of the motors backward. I don't know if it would work here or not, just an idea.

Brijar!!! Slash 2x4 LCG Two Slash 4x4s Rustler |

|

|

|

|

|

(#54)

|

|

|

RC-Monster Aluminum

Offline

Posts: 748

Join Date: Oct 2005

|

12.29.2007, 11:48 AM

To solve problem with shaft length motor manufactures need to flip front motor cover and have bearing sticking out like Lehner or Plettenberg motors, as well as brushed motors. That solution has as many "+" and "-", but does help with shaft (plus extra room inside motor can for windings and magnets), not good for mounting screws...

For Traxxas: why not to redesign slipper, put spur gear in place of slipper? - not easy access to spur, Ok - it is great spur + dust from slipper ends up being further from motor bearings +/- access to slipper itself    |

|

|

|

|

|

(#55)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

12.29.2007, 02:05 PM

Thats a good point. So far as the reversed motor mounting thing goes, it works perfectly with the old tranny. One would place short spacers between the existing motor mount and then bolt another one (mount) on top as it were using the gear cove mounting screw holes, sandwiching the spur and slipper. It wont work with the new tranny mount easily since there is only one gear cover screw present....

|

|

|

|

|

|

(#56)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,436

Join Date: Nov 2005

Location: Edmonds WA

|

12.29.2007, 03:08 PM

So in the interest of "making this work". How about taking a second motor mount plate, trimming off about half of it, and bolting it onto the "factory" plate. Then mark the contact area of the motor on the factory plate, and trim that off (after removing the New mount, of course). Thus you've just made an offset motor mount, with the offset equivelent to the thickness of the motor mount plate.

|

|

|

|

|

|

(#57)

|

||

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

12.29.2007, 04:01 PM

That idea sounds very familiar:

Quote:

|

|

|

|

|

|

|

(#58)

|

||

|

RC-Monster Aluminum

Offline

Posts: 862

Join Date: Dec 2006

Location: Perth, Western Australia

|

12.29.2007, 10:09 PM

Quote:

|

|

|

|

|

|

|

(#59)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,436

Join Date: Nov 2005

Location: Edmonds WA

|

12.31.2007, 06:44 PM

|

|

|

|

|

|

(#60)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

12.31.2007, 09:01 PM

He he, apparently though Patrick had the same idea before me even, over on the noob forum. Im getting slow in my old age....

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode