|

|

|

(#16)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

02.08.2011, 11:16 AM

cant wait to see how your brace system works!

|

|

|

|

|

|

(#17)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 339

Join Date: Aug 2005

Location: Indiana

|

02.08.2011, 11:21 AM

Linc, awesome ideas! can you please take a pic with both of the cvds and dogbone side by side? just want to see how thick is the dogbone compared to the cvd shaft.

|

|

|

|

(#18)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.08.2011, 11:30 AM

I will make the other end at some point today and then take pics

I measured the parts and the lst cvd will add 15mm per side. That is the difference in the drive pin holes. Quote:

I have noticed that the lst2 cvd bone end is slightly smaller than the original savvy diff output cup. So I will take apart a diff and see if the lst cups will fit the savvy diff. |

|

|

|

|

|

|

(#19)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.09.2011, 09:03 PM

Pics for the driveshafts are on my phone and the auto upload to photobucket is not working. Go figure, it is a "smart phone", and I am a dumbass for buying it.

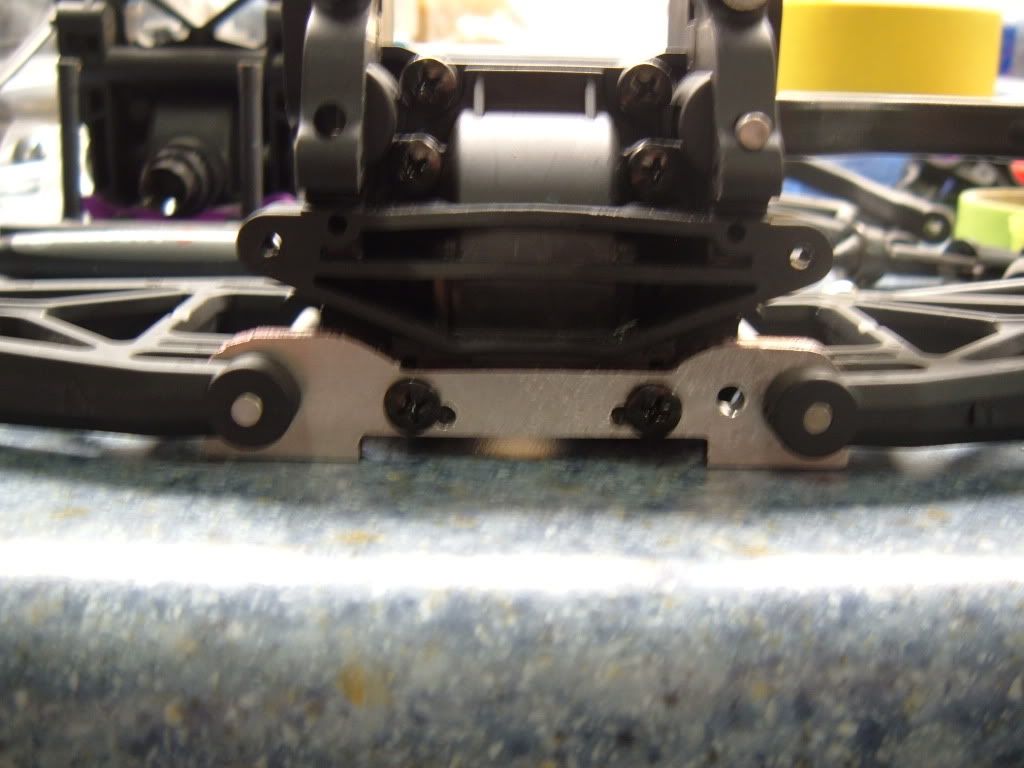

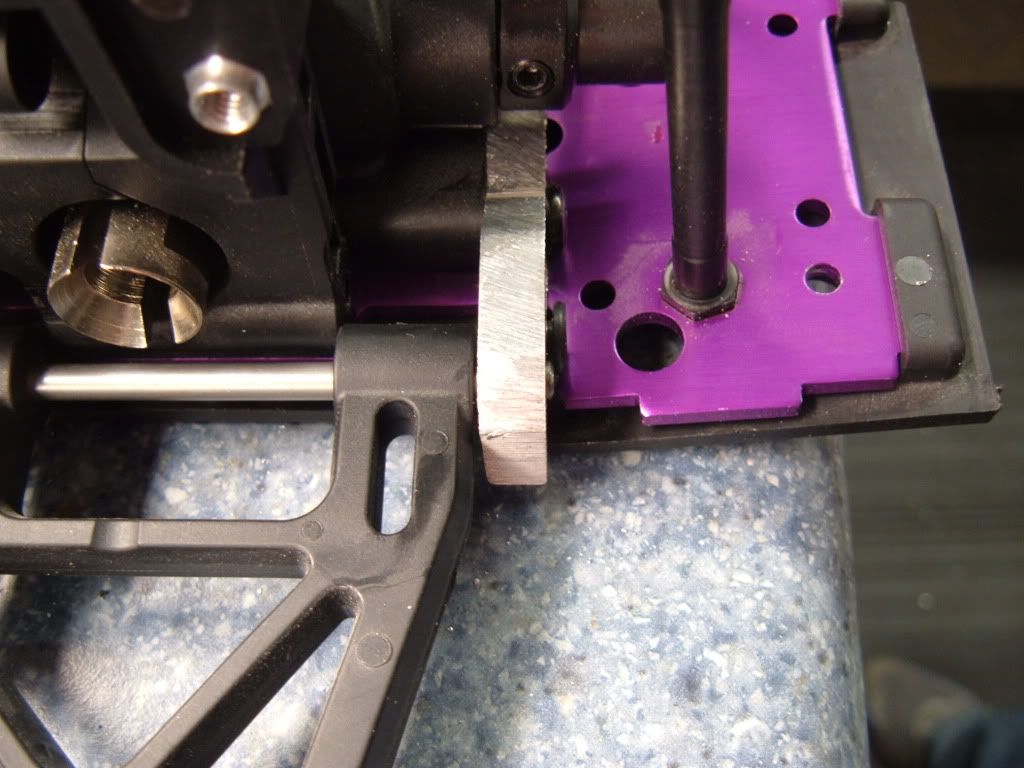

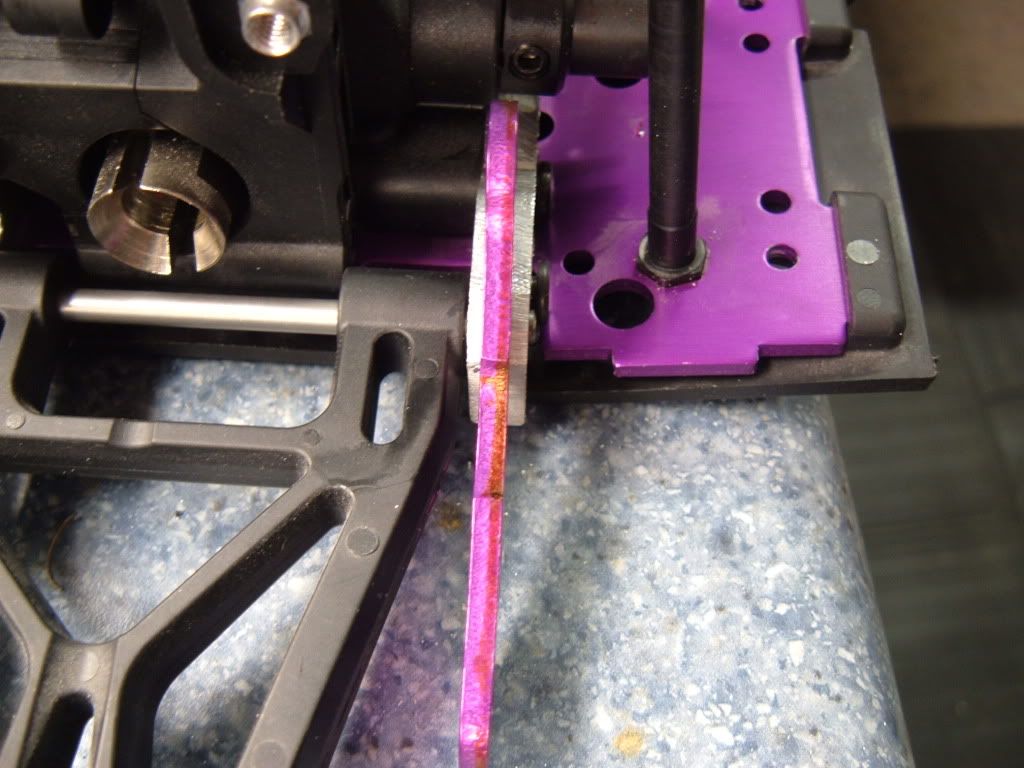

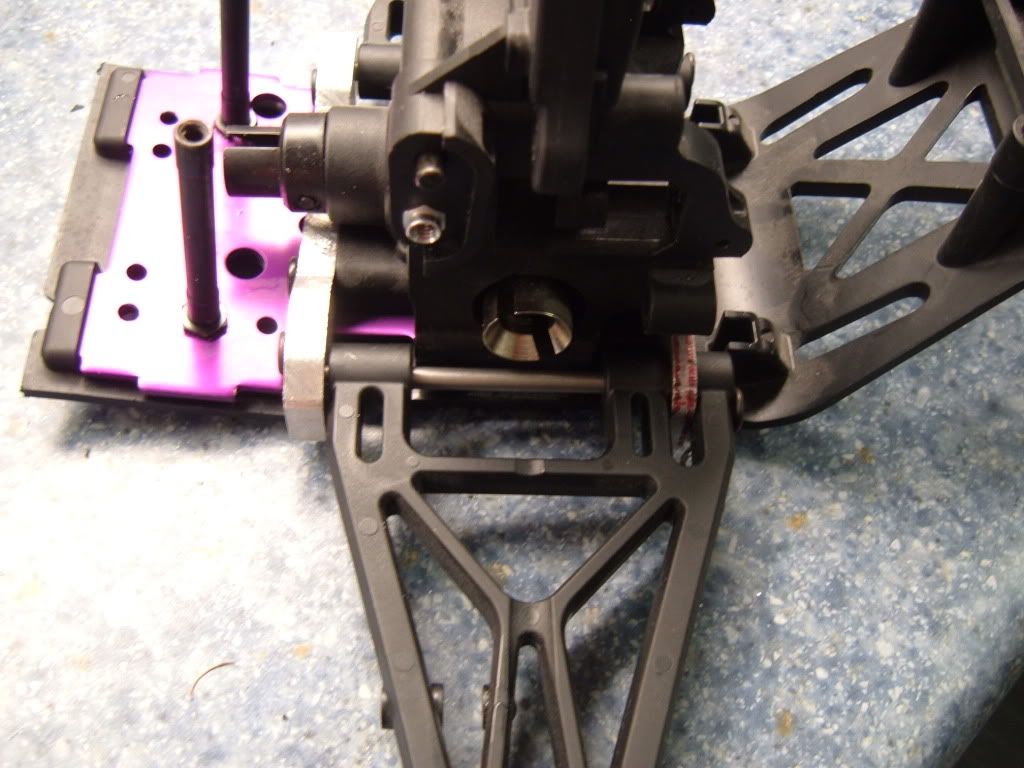

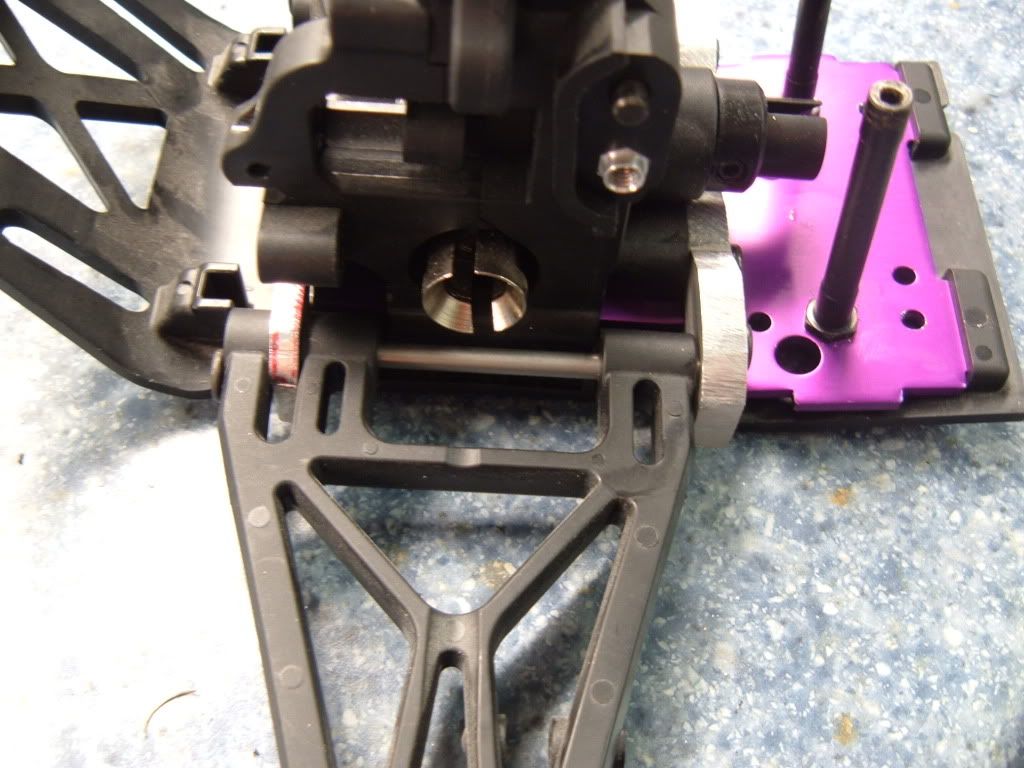

But the good old 3meg camera is working fine so here are some pics of the finished hingepin braces. Made out of 6061, not sure on the widths but the outside one is as thick as possible to fit in the slotted area of the arm (just slightly thicker than stock). The inside brace is easily 3 times thicker than stock. I had this material laying around, bought for some project at some point. I drilled and tapped the inside brace for 3mm screws to retain the pins, and did the same on the arms to keep the pin from getting out that way. Using the short traxxas servo screws, widest head m3 thread screw I had on hand. Did not want the threaded holes too close to the hingepin holes for strength reasons. One could make flat retainers that sit over the pin holes, like the ones pictured in post #4. I did not feel like cutting any more al so I did this. As soon as the turnbuckles show up I will assemble everything else.

|

|

|

|

|

|

(#20)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.09.2011, 09:06 PM

I did have to trimm off the stock hingepin retainers on the plastic skidplate. Not the ones on the bumper end, the ones closest to the pinion.

I also removed about 1mm of length on the hingpins, as they were slightly too long. This was very straightforward and easy. I could have done it all in under 1hr, and likely made both a ft and rear set in that time. |

|

|

|

|

|

(#21)

|

|

|

RC-Monster Aluminum

Offline

Posts: 897

Join Date: Mar 2010

Location: Same town as "Brand P"

|

02.09.2011, 09:33 PM

I think on the thick end you could have shortened the pin even more and then not drilled all the way through the hingepin brace. It would have eliminated the use for the retainer screw.

|

|

|

|

|

|

(#22)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.09.2011, 09:44 PM

Yes, this could be done. However I like being able to remove the pin from that end, the plastic skid does not have to come off for this. If you want the pins out the other way you have to remove it. Just 4 screws and the bumper mounts, but I like the option.

|

|

|

|

|

|

(#23)

|

|

|

RC-Monster Aluminum

Offline

Posts: 800

Join Date: Oct 2009

|

02.09.2011, 10:10 PM

Be interested to see what measurements you get for width from outside hex to outside hex.

From my measurements tonight I have: Savage X: 14.25" Savage XL: 15.25" RC8T: 15.125" I was a bit surprised by this. But on the flip side, the suspension arm is longer so the you should have more suspension travel. Also, the axles and extenders are far more robust than the Savage junk. |

|

|

|

|

|

(#24)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.10.2011, 12:17 AM

Quote:

|

|

|

|

|

|

|

(#25)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

02.10.2011, 09:21 AM

awesome job bud!!! looks very solid... im thinking some Titanium hinge pins to finish it off?

Have you got any pictures of the finished produt with the hubs and cvds installed? Can you please tell me what thicknesses of alloy did you use ? |

|

|

|

|

|

(#27)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,007

Join Date: Apr 2010

|

02.10.2011, 09:47 AM

Also because you now have the hinge pin pulled away from the bulk... doesnt this open a whole load of opportunity to run truggy arms and hubs instead...??? offering better steering possibilities?

BUT i am unaware of how strong truggy CVDs are? can they handle 6-10s power? |

|

|

|

|

|

(#28)

|

||

|

RC-Monster Aluminum

Offline

Posts: 800

Join Date: Oct 2009

|

02.10.2011, 11:09 AM

You can modify the bulkhead to allow the use of truggy arms; what creating new end plates does means that you don't have to modify the bulkhead and you get a bit more width, 30mm is what he's estimating now.

As far as how strong truggy arms/cvds are. Its a give and take. Truggy arms are usually made of stiffer plastic to reduce flex, etc. to give more predicatble handling, etc. So while they seem to be tougher, they may break when the Savage arms end up flexing a bit. As far as the CVDs... I bash my RC8T with no problems on 6S on a MMM with a 1518. But once again, its a trade off. Truggies are meant for racing, so things need to be decently tough, but also lightweight. The shafts on my RC8T are 3.75mm diameter vs the 5mm diameter of the Flux drive shafts. The axles are 8mm just like the Savage, but use truggy adapters with the pin going through the adapter and axle, unlike the Savage. All in all I would say that it should probably handle 10S. But then again, 10S is frankly on the ultra extreme end, unless you are running a really lower KV motor (something between 1000 and 1580). After all an out of the box Flux running 10S on 1580kv with 1.07 rollout (out of the box is 1.26) is like ~58.91mph according to Script Asylum calc. If you are running a lower Kv motor, I would think that the 8-10S won't matter on the abuse of the parts, other than added weight of the batteries. Quote:

|

|

|

|

|

|

|

(#29)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 339

Join Date: Aug 2005

Location: Indiana

|

02.10.2011, 11:18 AM

Quote:

People have been using Jammin CRT universals on their supermaxx but they did not last long.. Wish the ue supersavage cvd is still in stock. I bet that is the best money can buy for the savage owners. |

|

|

|

|

(#30)

|

|

|

RC-Monster Aluminum

Offline

Posts: 800

Join Date: Oct 2009

|

02.10.2011, 11:35 AM

Yes, that is true. However a Flux and a e-truggy aren't that far apart in weight and both are fairly rugged 8th scale vehicles; if I recall I think my truggy is like 9lbs or so loaded for bashing and my nitro Savage is like 10 or 11 and about that in Flux mode too.

Talking about 10th scale or smaller vehicles is kinda pointless. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode