|

|

|

(#46)

|

|

|

RC-Monster Stock

Offline

Posts: 49

Join Date: Apr 2008

|

12.27.2012, 10:44 AM

you did the forward only conversion as well I assume? I think I'm going to ditch the mechanical brakes when I redo this. they were a pain to change the first time anyway.

But if you ditch the 2 speed, then the motor heats up a lot more because you don't have the lower gear to start it off right? Quote:

|

|

|

|

|

|

(#47)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 280

Join Date: Apr 2008

|

12.27.2012, 10:58 AM

Well, you need to gear appropriately for your motor & wheels too.

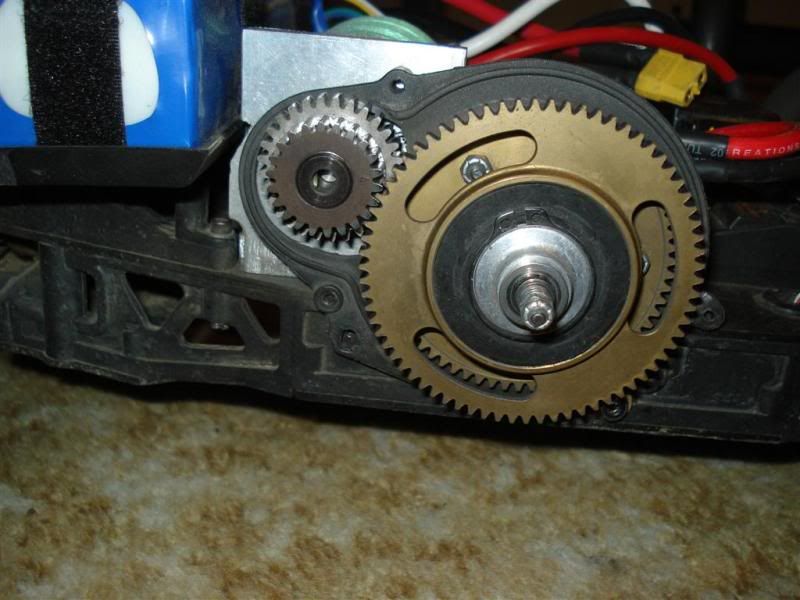

I originally built this as a racer with a .32 engine, then converted it years later. So, it was already sporting the FOC kit with a gear flip which increases speed. I have also changed the bevel gears to the higher ratio for more speed since being converted. I'm using a motor much bigger than yours because I wanted the torque to be able to gear up for insane speeds. Last clocked chasing with a car at 100km/h at 3/4 throttle (still to try the 34T pinion on the freeway). My motor gets to about 65-70 degrees Celsius, not sure of Fahrenheit, after a full pack doing WOT runs. ESC has a fan & it rarely turns on. Unless it's a 30+ degree day. If I gear down it will flip constantly, but, this is still a wheelie king!! Another thing, I soon discovered that my truck was mostly starting off in 2nd gear anyway as the torque produced was overriding the two-speed clutches instantly! This next video is running my original setup (See pic) which was a +4 over stock on metal gears which explains the ringing noise in the camera.  http://www.youtube.com/watch?v=gmbs_-iFO9A MP7.5 Kanai III Tekno Neu 1515/2.5D 1700kv MM 4S LST 2 Carbon CC 1717 1Y 1580kv MM 6S Futaba 3PKS Spektrum Pro |

|

|

|

|

|

(#48)

|

|

|

Destroyer of Tires

Offline

Posts: 626

Join Date: Feb 2009

|

12.27.2012, 01:57 PM

A 36mm motor will bolt into the Losi mount, the mounting pattern is the same. Your 11xl motor is a older design 2 pole that now a days would be considered marginal depending on how fast you want the truck to go. They're not bad motors, things have just improved so much. The 2 speed does decrease the load on the motor at lower speeds and from a stop decreasing temps somewhat. You also have the advantage of a pretty low Kv and higher voltage improving efficiency and lowering temps also.

If it were me, I'd try it as a single speed with your motor and go from there. Try gearing it for about 40mph or with a pinion that has the same tooth count as first gear. You might have to add a heatsink/fan but that's pretty common for those motors. Some more detailed info on your current setup and future plans will help. Motor Kv, current esc and future, current gearing 1st and 2nd, tire size, etc. |

|

|

|

|

|

(#49)

|

||

|

RC-Monster Stock

Offline

Posts: 49

Join Date: Apr 2008

|

12.27.2012, 03:47 PM

Quote:

I would like to go with a hobbywing ezrun 150amp esc or the turnigy 150amp although probably the hobbywing as it seems to have a much better rep and its only like 12 bucks more. That opens up the option of going single speed and forward only which i'd like to do as I much prefer the motor braking. One big question is I see pretty much all the motors are 2000KV and higher and that seems what everyone is running. Can I run that type of KV on 6s? I'd prefer to be able to buy a simple 40 dollar brushless motor and replace it if needed. Don't have the bucks for the expensive stuff. When I did the conversion years back, I was told you needed lower KV , but I seem to be reading a number of places that people are using these higher KV motors on 6S. EDIT: one other thing, are there other motor mounts for this truck besides TDR, Losi and Fine Design? Just wondering because I see a number of motors with heatsinks built into the casing and pretty sure those aren't fitting in the losi mount and definately won't fit the FD mount which leaves the TDR mount which IMHO looks like the best option, but its also quite pricey. |

|

|

|

|

|

|

(#50)

|

|

|

Destroyer of Tires

Offline

Posts: 626

Join Date: Feb 2009

|

12.27.2012, 11:24 PM

An airplane esc generally isn't as smooth as a car esc. The Hobbywing will be more controllable as it is programmed for car use. The reason you see more higher Kv motors out now is because the most popular conversions are buggies and truggies. Most of them are limited to 4s use in the classes they race in and 4s is cheaper for bashers too so higher Kv sells better. All else being equal (including top speed) a lower Kv with higher voltage will be more efficient than higher Kv and lower voltage. Motors like the 11xl needed to be lower Kv with higher voltage to pull around larger trucks like the LST.

The Losi mount has a 43mm diameter so it will take a Castle, Tekin or most any finned motor. But those fins don't contact the mount causing it to hold heat in, plus it's limited in its gearing. If you kept the Kv around 1500 you could run 6s (stock trans gearing) with the Losi mount, but 2200kv you would need to drop down to 4s to keep the speeds and temps in check. I wouldn't recommend the 11xl or similar 36mm motor in the Losi mount. |

|

|

|

|

|

(#51)

|

||

|

RC-Monster Stock

Offline

Posts: 49

Join Date: Apr 2008

|

12.27.2012, 11:47 PM

so are there any reasonable priced low kv motors you could recommend? otherwise i might end up going 4-5S when this motor burns out.

Quote:

|

|

|

|

|

|

|

(#52)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 280

Join Date: Apr 2008

|

12.28.2012, 01:19 AM

Look for a Leopard 4082 1600kv & you can run 6S. They are sold from Hong Kong on ebay. Free postage too!

The larger the diameter & longer the can the more torque it will produce over a smaller size can with the same kv. So. don't just think a lower kv will improve things without taking into account the can diameter & length. It is smooth canned & will fit a Losi mount. I use this in my 1075mm Cat boat running twin 6S in parallel. It goes ok. http://www.youtube.com/watch?v=eJO5N0Wh4eU MP7.5 Kanai III Tekno Neu 1515/2.5D 1700kv MM 4S LST 2 Carbon CC 1717 1Y 1580kv MM 6S Futaba 3PKS Spektrum Pro |

|

|

|

|

|

(#53)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 129

Join Date: Jul 2011

|

12.28.2012, 04:33 AM

I like how you put that "it goes OK" 1:30 into the video and its screaming across the water! I've been looking into the leopard 4082 1600kv for my conversion. I have a castle 1520 but don't want to keep taking the motor out of my truggy to use it. I've heard good things about it so far

|

|

|

|

|

|

(#54)

|

||

|

RC-Monster Stock

Offline

Posts: 49

Join Date: Apr 2008

|

12.28.2012, 10:25 AM

That motor doesn't look bad at all especially for the price. Would anyone here recommend sensored over sensorless or does it not really matter anymore?

Quote:

|

|

|

|

|

|

|

(#55)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 280

Join Date: Apr 2008

|

12.28.2012, 12:24 PM

Sensored is more suitable for racing applications where you want a very precise feel at low RPM. Like exiting a slippery corner.

Sensorless is better for high power requirements. I use the Mamba Monster with the 'Torque Control' setting active & no 'Punch Control'. It seems to be much smoother to drive. This ESC has given me hours of 'driving pleasure' with no fuss at all. I update the software regularly & it never misses a beat. MM's are not too badly priced from ebay either. If you want a motor that they don't currently have in stock, just email them & they should be able to give you an indication of a restocking date. I bought mine from ebay, along with the water cooling jacket. BTW, I don't think the boat is quick yet. I'm upgrading my ESC to a 240HV & running it on 8S.

MP7.5 Kanai III Tekno Neu 1515/2.5D 1700kv MM 4S LST 2 Carbon CC 1717 1Y 1580kv MM 6S Futaba 3PKS Spektrum Pro |

|

|

|

|

|

(#56)

|

||

|

RC-Monster Stock

Offline

Posts: 49

Join Date: Apr 2008

|

12.28.2012, 01:49 PM

what makes sensorless better for high power applications? Finally got the truck out again today with my son and his mini summit. Complete disaster, it has so much power it just flips over constantly. I had an aluminum wheelie bar that sheered all four bolts holding it on. Looks like I"m looking for a new one unless I can figure something out.

I also think I damaged the transmission as its making a funny sound now. Still driving fine but definately making a different noise than it was. any ideas how to calm this thing down? One speed conversion probably calm it down I assume, not really sure how the pinions work on this since I guess you have to replace both of them if I wanted to go smaller pinions or something while I have the 2 speed. As for temps, battery was slightly warm, 6s 3000mah 20-30c pack, ESC was quite warm to hot and motor was pretty hot. Hot enough that you wouldn't want to touch it for more than a quick second. Sorry can't be more precise than that, I used to have a temp gun when it was nitro, but it died and I haven't needed one since. Quote:

|

|

|

|

|

|

|

(#57)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 280

Join Date: Apr 2008

|

12.30.2012, 03:02 AM

You may not have damaged anything, the motor mesh may have moved. That's happened to me in the past. I have beaten the crap out of my truck & never had the transmission or diffs let go. They are still the stock LST2 stuff.

I don't think your battery is able to cope with the required amp draw. You should increase both the C rating & mAh/capacity of the pack. Always have batteries that can deliver at least 20% more power than you require. I use the Turnigy 6S 4000mAh 40C packs & they barely get warm. As for 'calming things down' adjust the power setting lower in the ESC. Spoon feeding people is not my idea of education. Do some research, Prof. Google is there for a reason. Here are a few links which you should read before asking anymore questions. The first one is pretty good & has pics. The rest are just forums. http://rctruckstop.com/2011/12/15/br...vs-sensorless/ http://www.rcgroups.com/forums/showthread.php?t=975447 http://www.rctech.net/forum/electric...ensorless.html http://www.ultimaterc.com/forums/sho...d.php?t=140618 http://www.hobbytalk.com/bbs1/showthread.php?t=226007 MP7.5 Kanai III Tekno Neu 1515/2.5D 1700kv MM 4S LST 2 Carbon CC 1717 1Y 1580kv MM 6S Futaba 3PKS Spektrum Pro |

|

|

|

|

|

(#58)

|

||

|

RC-Monster Stock

Offline

Posts: 49

Join Date: Apr 2008

|

12.30.2012, 11:56 AM

I know you mean well, I've been reading everything I can find on this stuff. I checked the gear mesh, spurs and pinion look fine. mesh seems okay. I'll have to tear it down when I have the chance to check it out more. I think hitting the palm tree at full speed didn't help it :) It was far out and I didn't judge it right and smacked into the tree.

Anyway, The battery at the end of the pack is warm and nothing else so I think its okay. I can't calm it down with the current ESC, but I think the gearing needs to be changed. otherwise it will wheely all the time with no end in sight. I used to race all sorts of brushed cars 20 years ago, I'm just not really familiar with this one when it comes to setting up this brushless conversion. Quote:

|

|

|

|

|

|

|

(#59)

|

|

|

Destroyer of Tires

Offline

Posts: 626

Join Date: Feb 2009

|

12.30.2012, 05:27 PM

Switching to a single speed is going to calm the wheelies a littleif you keep the same top speed gearing. Right now you're geared for about 44mph btw. But it sounds like your motor is already at its temp limit, I'd seriously consider a new motor.

From what I remember the Fine Design kit placed the battery out back, I'd consider moving it up front to help curb the wheelies also. As far as your weird sound, its likely not the trans, the diffs are more likely to blame. Factory shimmed diffs are tough, but don't always hold up very well to brushless power. Your palm tree incident may have something to with it too. I actually cracked a front diff case in an impact, no other damage was done either. |

|

|

|

|

|

(#60)

|

||

|

RC-Monster Stock

Offline

Posts: 49

Join Date: Apr 2008

|

12.30.2012, 05:52 PM

Quote:

I noticed the back center drive shaft is a little bent. diffs seem good. checked the gear mesh earlier and it looked okay. i'm gonna rip the tranny down to do the forward only once I get new esc anyway. I'll have to get this kit soon I think, that fine design motor mount isn't the best, screws it comes with would make you laugh, i'm afraid to take them out as I know they will never go back in again without stripping. |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode